AtomMash Launches ‘Spider Robot’ to Enhance Nuclear Plant Safety

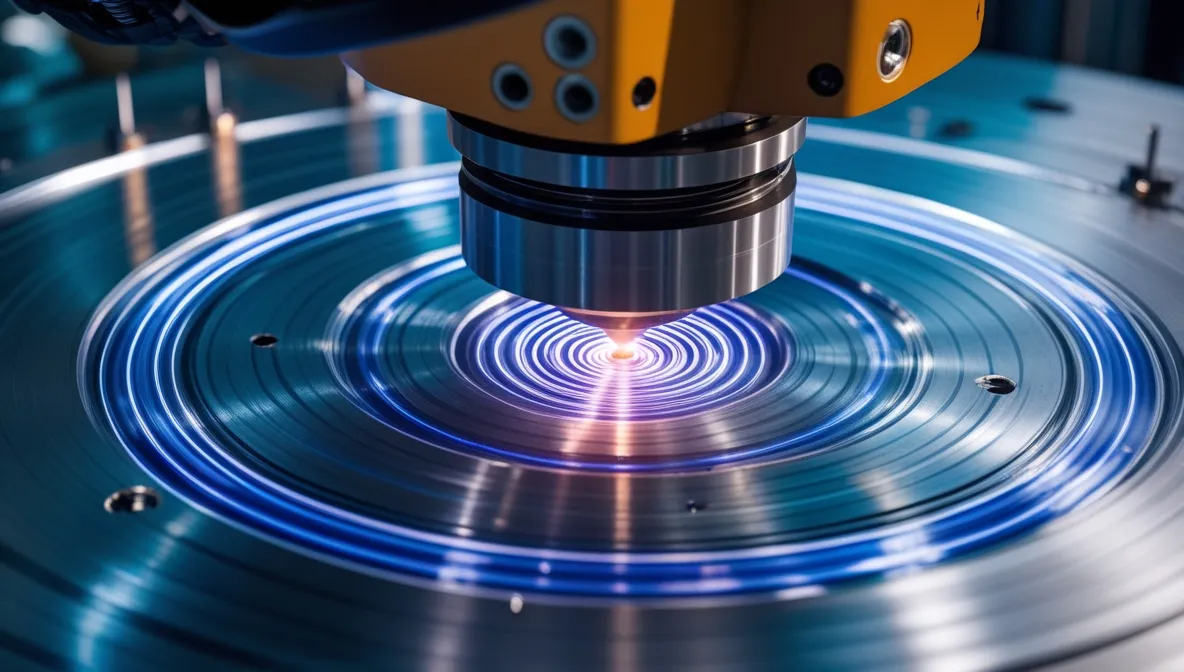

At the AtomMash plant in Volgodonsk, part of Rosatom’s engineering division, a new ‘spider robot’ equipped with advanced ultrasonic technology is transforming weld inspection for nuclear reactors — working three times faster than a human and eliminating human error from critical safety checks.

A Revolution in Quality Control

In October 2025, AtomMash, the engineering arm of Rosatom, introduced a next-generation ultrasonic inspection system in the form of a spider-like robot designed to test the weld seams of reactors and steam generators. The robotic complex performs quality control on welds up to 30 cm thick — three times faster than manual inspection — and ensures unparalleled accuracy even on complex geometries and hard-to-reach surfaces.

Ultrasonic testing relies on acoustic waves to detect internal flaws in welded joints. Traditionally, skilled technicians manually position sensors and interpret signals — a process vulnerable to fatigue, subjective interpretation, and error. A single mistake could result in equipment failure, radioactive leakage, or even a nuclear accident.

Why This Matters

The integrity of a welded joint is the foundation of nuclear reactor safety. Even a tiny flaw in a steam generator or pressure vessel weld can lead to catastrophic consequences. Historically, inspections have been carried out manually by certified technicians — a time-consuming and highly specialized process, often affected by human error.

The spider robot eliminates these challenges. It performs inspections three times faster than humans, guarantees consistent precision independent of operator fatigue, and can operate in confined or hazardous environments, including the inner cavities of steam generators. Its onboard algorithms analyze echo signals with microsecond precision, detect sub-millimeter defects, and generate detailed 3D maps of weld structures — a leap forward for nuclear safety worldwide.

Import Substitution as a Strategic Priority

The development of industrial robotics for the nuclear sector is now one of Rosatom’s key priorities amid geopolitical restrictions. Until 2024, Russian plants relied heavily on foreign automated inspection systems — mainly Western and Japanese models. Sanctions accelerated the push toward domestic innovation.

Rosatom’s subsidiary, AtomIntelMash LLC, is developing a new generation of industrial robots for welding, mechanical, and inspection tasks. The state corporation aims to capture 50% of the Russian industrial robotics market by 2030, manufacturing up to 3,000 units annually with projected revenues of roughly $72 million.

Precision as the Core of Safety

Ultrasonic flaw detection works on the echo principle: the robot emits ultrasonic waves that reflect off defects or material boundaries and analyzes the returning signals. The quality of results depends on the sensitivity of sensors, wave frequency, scanning angle, and material properties.

The latest-generation transducer on the spider robot detects various defect types — cracks, pores, incomplete fusion, inclusions, and delaminations. The robot automatically adjusts its scanning parameters to suit each weld’s geometry and material, something manual inspection simply cannot achieve. Results are stored in a centralized database, forming a complete diagnostic record for each reactor component.

For nuclear power, this level of precision is critical. Even a microscopic defect can cause corrosion, fatigue fractures, or pressurized leaks within the reactor vessel.

Export and Industrial Potential

Once the technology’s reliability is fully demonstrated, it could be applied beyond nuclear power — in shipbuilding, pipeline infrastructure, petrochemical plants, and rail systems. Globally, automated weld inspection is in high demand, though it requires international certification to meet strict safety standards.

This innovation underscores the capacity of Russian engineers to develop advanced technologies for the most demanding industries. In nuclear power, safety now depends not only on human expertise but increasingly on precision data and intelligent algorithms.