To the Depths Below – Digital Moles

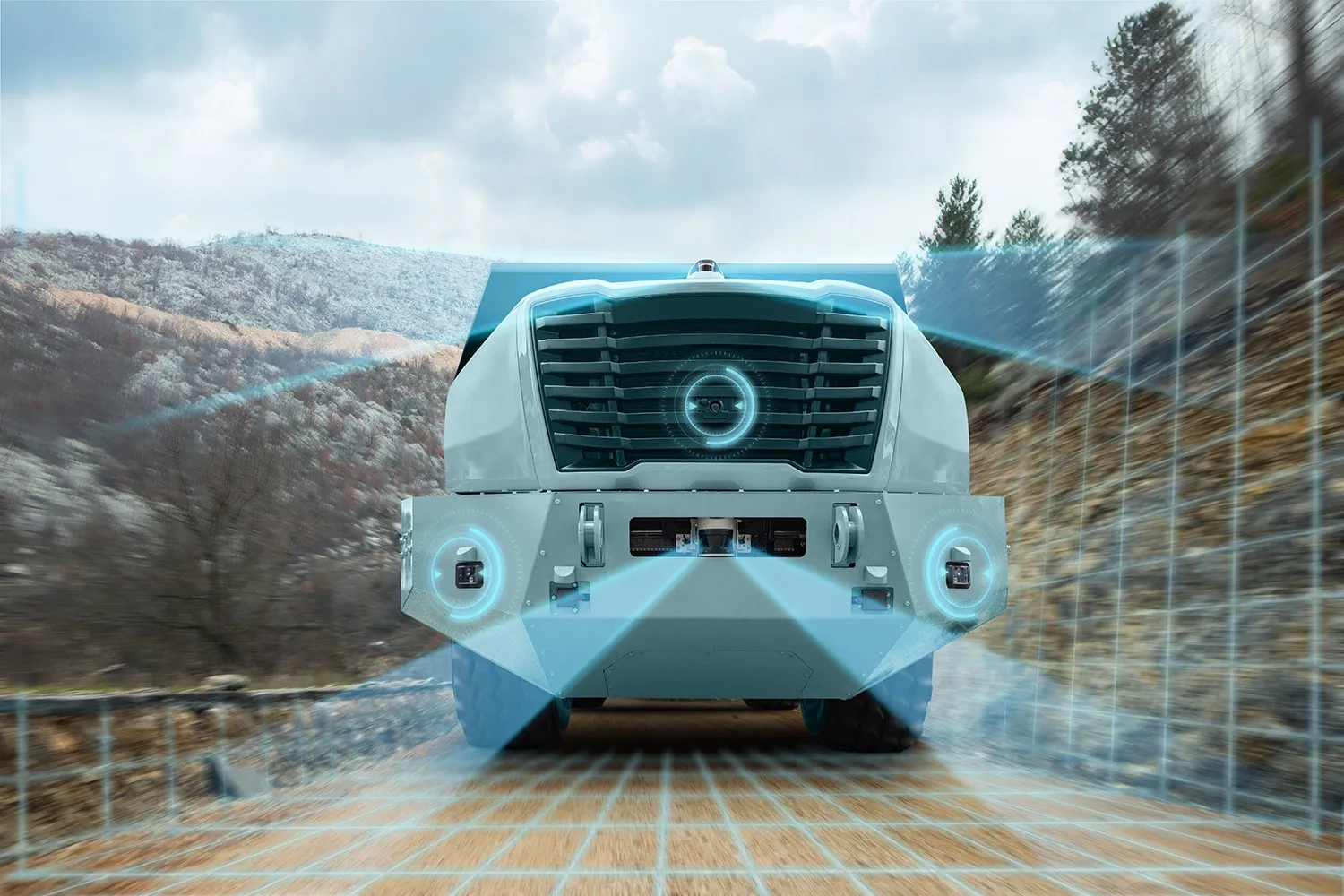

As the mining industry undergoes a technological transformation, Russian engineers and students are pioneering a breakthrough system that could change how underground development is done. A collaboration between Sirius University and VNIIPIpromtechnology has produced a prototype of an autonomous tunneling robot control system — aligning with global digitalization trends in mining.

Underground GPS for the Digital Age

At the heart of the project lies a custom-built algorithm for autonomous underground navigation. Since GPS signals cannot penetrate below ground, the robot must navigate on its own using a synthesis of inertial positioning (an internal ‘step counter’ and turn detector) combined with preloaded 3D models of the mining environment. Picture a Mars rover — but working in the much tighter, more hazardous conditions of Earth's subsurface.

The project fits into a global trend:

analysts forecast that by 2030, up to 50% of newly developed underground mining

equipment will feature high levels of autonomy. Underground mining remains one

of the most dangerous industries worldwide. According to Russian statistics

agency Rosstat, the injury rate is significantly higher than the national

industrial average. Autonomous tunneling robots can take over some of the

riskiest tasks — minimizing human exposure. The logic is clear: 'better to lose

a sensor than a specialist.'

These robotic systems don’t require rest or shift changes. For them, 24/7 isn’t a slogan — it’s an operating mode. Early estimates suggest a productivity increase of 20–30% with autonomous deployment. At a strategic level, developing proprietary technologies for mining — a sector vital to Russia — reduces dependency on expensive foreign hardware and software.

Beyond Nuclear: Rosatom's Strategic Leap

This initiative showcases Rosatom’s strategic shift to expand its digital and robotics capabilities beyond the nuclear sector. VNIIPIpromtechnology, best known as the engineering brain behind the ambitious 'Breakthrough' nuclear project, is now applying its expertise to the mining sector. The skills honed through years of digital engineering (BIM) and robotics are being retooled for new industrial challenges.

Sirius University, a leader in technology

education, serves as the ideal innovation hub. This isn’t its first robotic

collaboration: earlier prototypes of tunneling robots for the Breakthrough

project laid the groundwork. Now, students from Russia’s top technical

universities — including MEPhI — are collaborating directly with

VNIIPIpromtechnology’s industry veterans, bridging the academic-industrial

divide. These collaborations are fertile ground for the next wave of startups

and disruptive technologies.

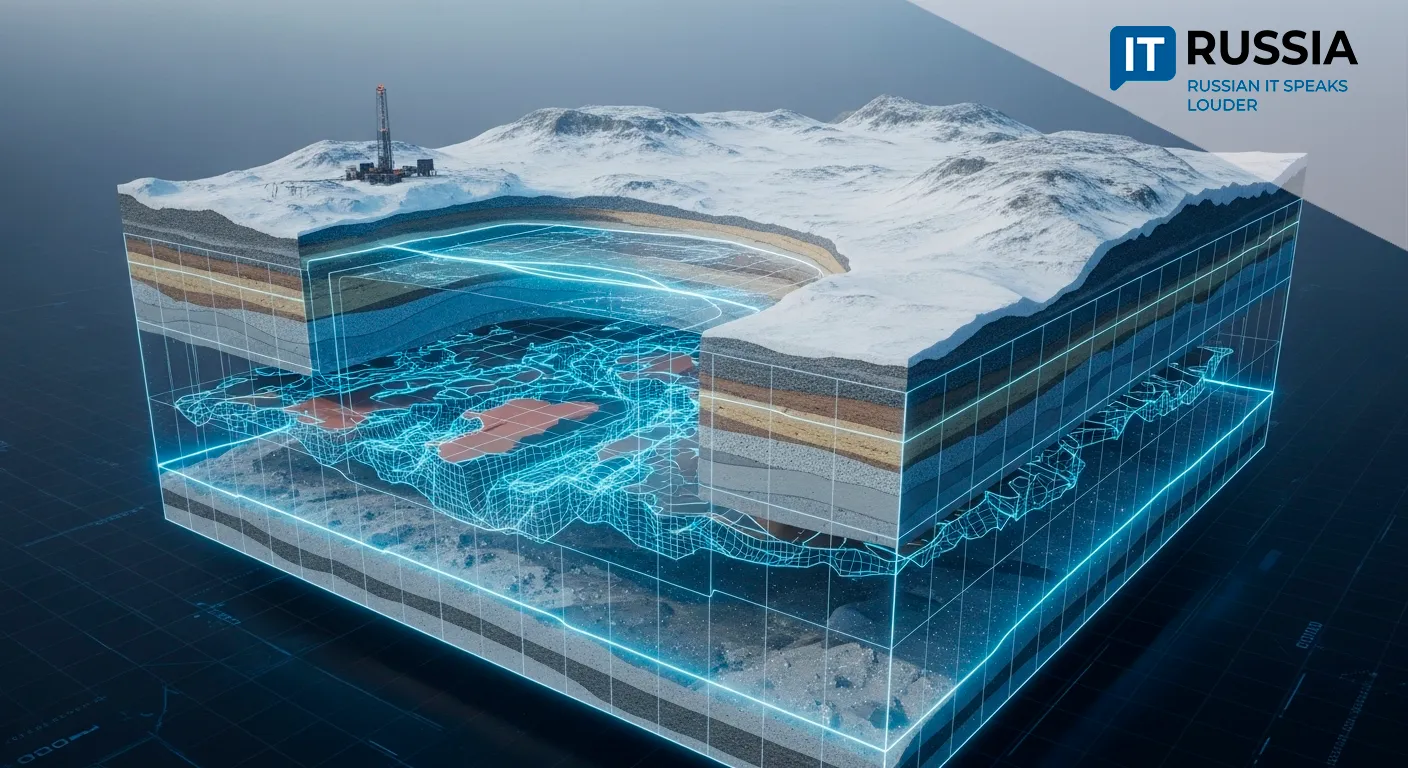

Built for Harsh Terrain — with Global Potential

The system is particularly relevant for geologically complex regions like the Arctic and Russian Far East. While initial deployments will focus on domestic operations, the project has export potential. GPS-free underground positioning is gaining traction worldwide. Russian-developed algorithms, tested under severe conditions, may appeal to mining markets in Canada, Australia, and South Africa. The global mining tech industry is watching — and Russia has positioned itself to lead.

Pilot deployments at Russian mining sites

are expected within the next 2–3 years. These trials will further refine

navigation algorithms and integrate the system with other robotic platforms,

such as drilling and blasting units. The next critical steps will include

industrial certification and scaling up deployment.

What began as a summer student project in Sochi now looks like a strategic investment. The 'digital mole' may well redefine safety and efficiency standards in underground mining. By connecting its engineering centers and university research labs, Rosatom is proving that academic-industry collaboration can yield real-world innovations. Who knows — Russian navigation algorithms may soon be guiding tunnelers not just in Siberia, but beneath the mines of Australia and Canada.