Every Third Barrel Is Digital: Russia’s Oil Sector Accelerates AI Integration

More than one-third of the oil produced by Russia’s Neftisa Group now involves AI and digital tools—a sharp rise from just 13% in 2022, signaling the country’s rapid digital transformation in energy extraction.

AI-Powered Pump Monitoring: A Breakthrough in Udmurtia

One of Neftisa’s production facilities in Udmurtia recently patented a homegrown digital assistant that automatically analyzes dynacards—graphs tracking the performance of downhole pumps. The process is comparable to using an ECG to monitor a well’s health.

Previously, engineers manually reviewed hundreds of these charts to detect signs of failure, like equipment wear or sand intrusion. Now, AI scans them instantly and continuously, flagging anomalies and emailing alerts to relevant engineers in real time.

This neural network replaces hours of tedious analysis, freeing expert personnel to focus on complex challenges. The results? Higher efficiency, improved safety, and lower operational costs—all driven by Russian-developed software.

Beyond Algorithms: Building a Digital Oil Ecosystem

This initiative aligns with Russia’s national Digital Energy Strategy 2030, which provides a regulatory framework for the sector’s digital shift. What distinguishes Neftisa’s progress is that it’s no longer hypothetical—it’s proven and measurable.

Creating sophisticated tools like AI assistants drives R&D, enhances local expertise in machine learning, big data analytics, and industrial IoT, and spurs demand for a new class of professionals—'digital oil workers' fluent in both geology and Python. By deploying its own platforms, the sector reduces dependency on imports and stimulates regional tech ecosystems and innovation clusters.

The Russian Way: Parallel to the Global Trend

While international majors like Shell, ExxonMobil, and Saudi Aramco are also deploying digital technologies, Russia emphasizes sovereign platforms and import substitution. Its oil sector mirrors global digitalization trends—but on an independent path.

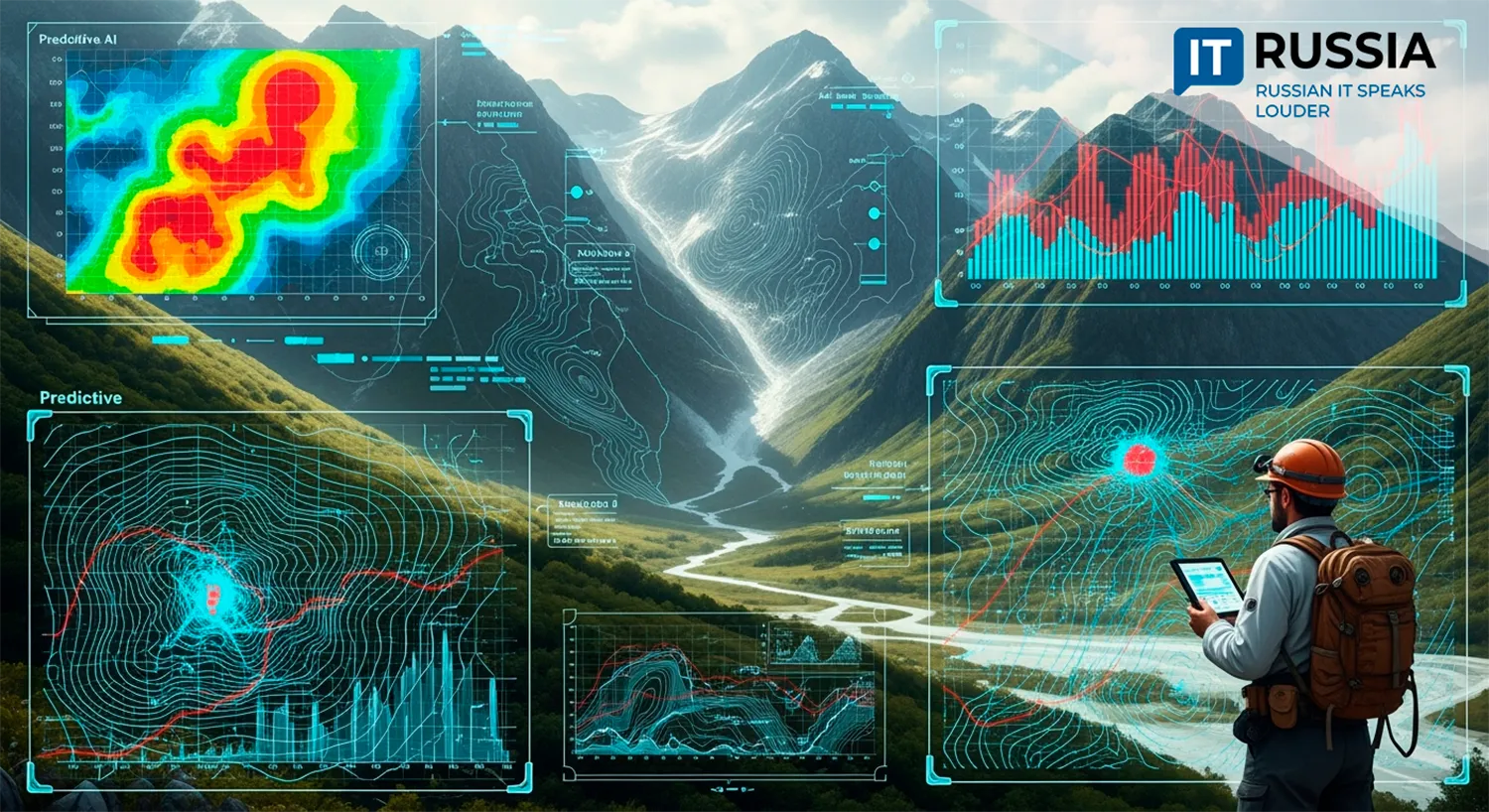

AI tools are evolving from diagnostics to full operational control. Today’s digital managers oversee predictive maintenance, reservoir flooding optimization, hydraulic fracturing, and logistics. Wells are beginning to 'speak'—and digital systems are listening and responding.

These advances rest on years of groundwork: Gazprom Neft’s Digital Transformation Center, over 30 in-house digital products, and flagship AI systems like ERA:ISKRA (drilling simulation) and ERA:OptimA (hydraulic fracturing optimization). MessoYakhNeftegaz pioneered digital twin field models and autonomous drilling cycles in Tyumen. And the federal TRIZ program (Hard-to-Recover Reserves), launched in 2021 with Gazprom Neft, has already cut the cost of developing such reserves by a factor of three.

Russia’s 2025 investment outlook projects up to RUB 3.8 trillion in the energy sector, much of it dedicated to digital innovation.

Data Is the New Oil

The jump from 13% to 34% in just two years marks a transition from pilot projects to large-scale digital deployment. If the industry ensures data quality and accessibility, strengthens cybersecurity infrastructure, builds legal frameworks, and develops integrated digital platforms, full-scale scaling will be within reach.

For now, Russia’s energy sector is rewriting its operational code—and domestic software developers are becoming co-authors of that transformation.