Digital Disruption in Petrochemicals: How AI Is Making SIBUR Cleaner and Smarter

Since 2018, SIBUR has been rolling out artificial intelligence across its operations — from logistics and quality control to emissions management. The results speak volumes: in just six years, the company has reported over 45 billion rubles in combined economic gains, with nearly half attributed to AI-based solutions. One standout innovation is the EKONS recommendation system, which helps optimize gas processing facilities in Russia’s Khanty-Mansi and Yamalo-Nenets regions.

AI as a Driver of Efficiency and Sustainability

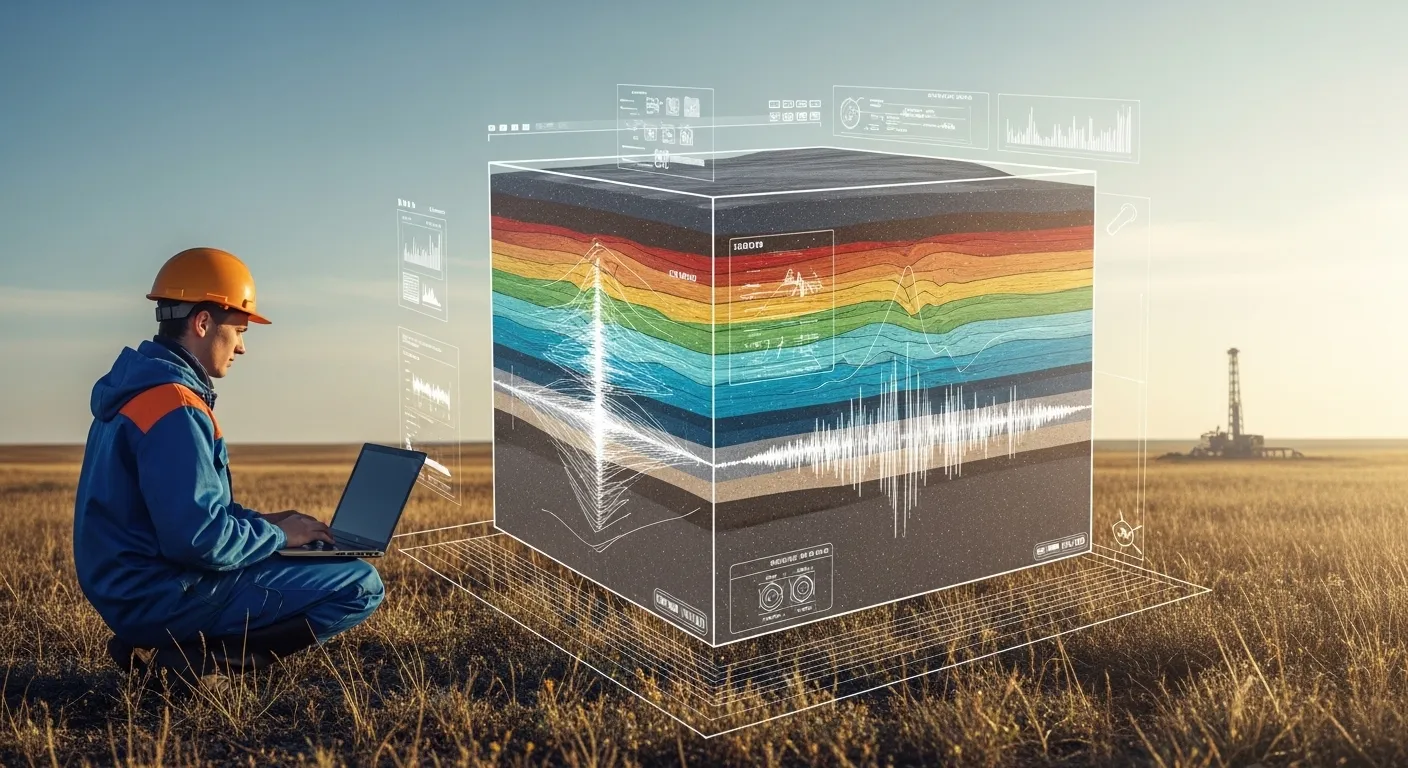

With over 25 industrial sites and tens of thousands of assets, SIBUR relies on digital ‘autopilots’ that provide operational suggestions or autonomously adjust production regimes. Computer vision systems — like the 'Black Screen' — prevent emergencies in real time, while predictive analytics monitor more than 600 parameters per unit every few minutes to prevent malfunctions.

AI is also used to forecast raw material prices and product demand. From 2021 to 2022 alone, predictive diagnostics saved the company over 1 billion rubles.

Smarter Algorithms, Cleaner Output

Today, SIBUR runs more than 20 recommendation systems, and 70% of its surveillance cameras are AI-enabled. Tasks that might take a human analyst years can now be resolved in minutes by algorithms.

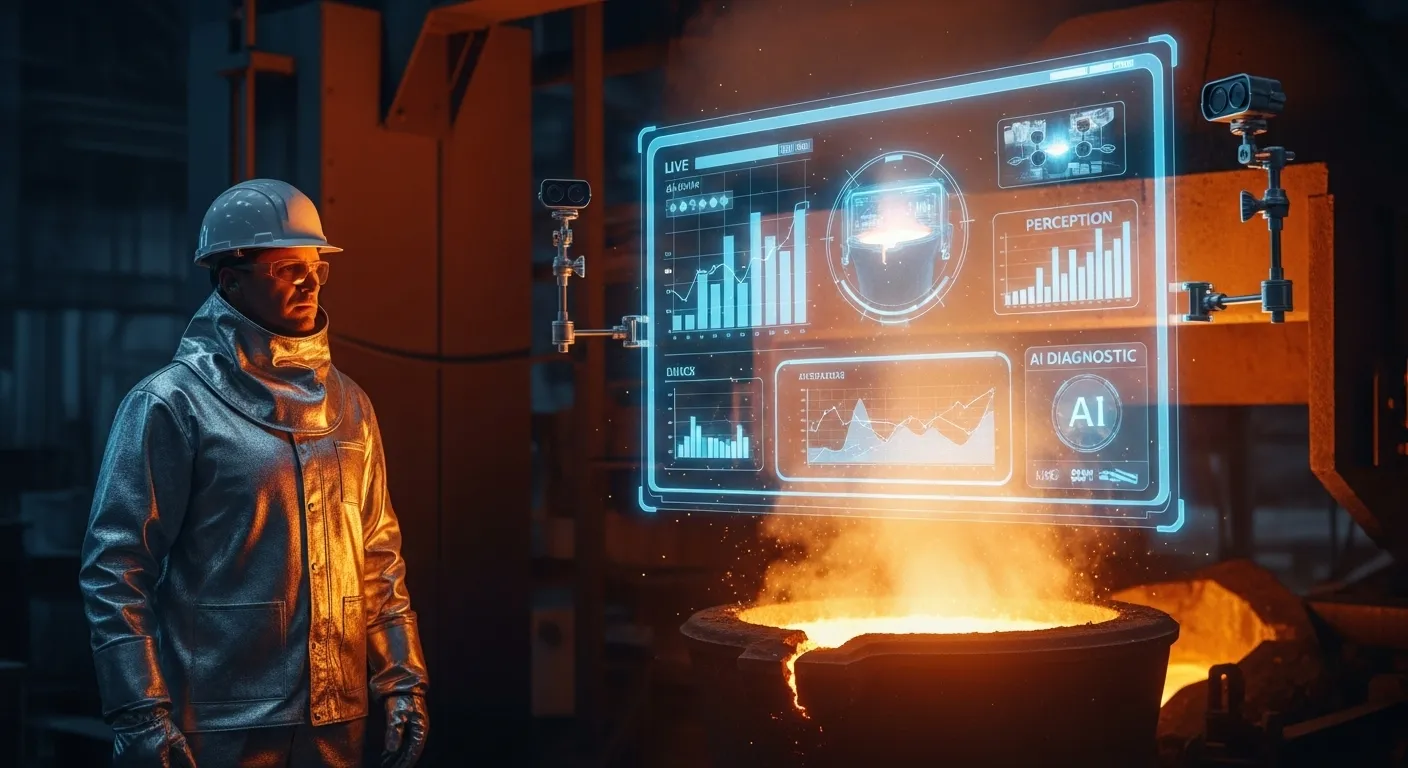

At the core of this transformation is EKONS, an AI tool that uses complex mathematical models to calculate key production indicators in real time. Operators get instant feedback — green means profits, red means losses. Adjustments can be made within seconds, improving both financial performance and environmental efficiency.

At the ZapSibNeftekhim plant, for example, more efficient fuel gas usage reduced CO₂ emissions by 80,000 tons per year. In Khanty-Mansi and Yamalo-Nenets, EKONS has already cut operating costs and increased productivity at critical installations.

Digital Tools with Global Potential

SIBUR’s digital push is reshaping Russia’s petrochemical sector, but its implications reach much further:

- Technology spillover: EKONS and other AI tools could be replicated across refineries and gas-chemical facilities in Russia. - Export-ready solutions: Video analytics and RTO optimization are already generating interest in CIS countries, China and India. - Domestic tech independence: SIBUR is developing its own AI-enabled cameras to reduce reliance on Western vendors.

What’s Next: AI-as-a-Service for Heavy Industry

Over the next three to five years, SIBUR plans to roll out its AI systems to new locations, including Kazanorgsintez and the Amur Gas Chemical Complex. It also aims to export its digital products to emerging petrochemical markets and build AI-as-a-Service platforms tailored to industrial needs.

In the long term, these initiatives promise to enhance Russia’s technological sovereignty while defining a new industry standard — one that is cleaner, safer and more competitive.