Russia Unveils Robotic Tomograph for Fusion Reactor Component Inspection

In a move set to streamline fusion reactor

assembly and quality control, Russian engineers have introduced an advanced

robotic tomograph that promises to cut inspection times from hours to minutes.

A Leap in Non-Destructive

Testing for ITER

In July 2025, Russia’s D.V. Efremov Scientific Research Institute of Electrophysical Apparatus (NIIEFA), part of Rosatom, together with Tomsk Polytechnic University (TPU), introduced a robotic ultrasonic tomograph for inspecting critical components of the International Thermonuclear Experimental Reactor (ITER). The system represents a breakthrough in non-destructive testing (NDT), enabling rapid, automated analysis of welds, material thickness, and structural integrity.

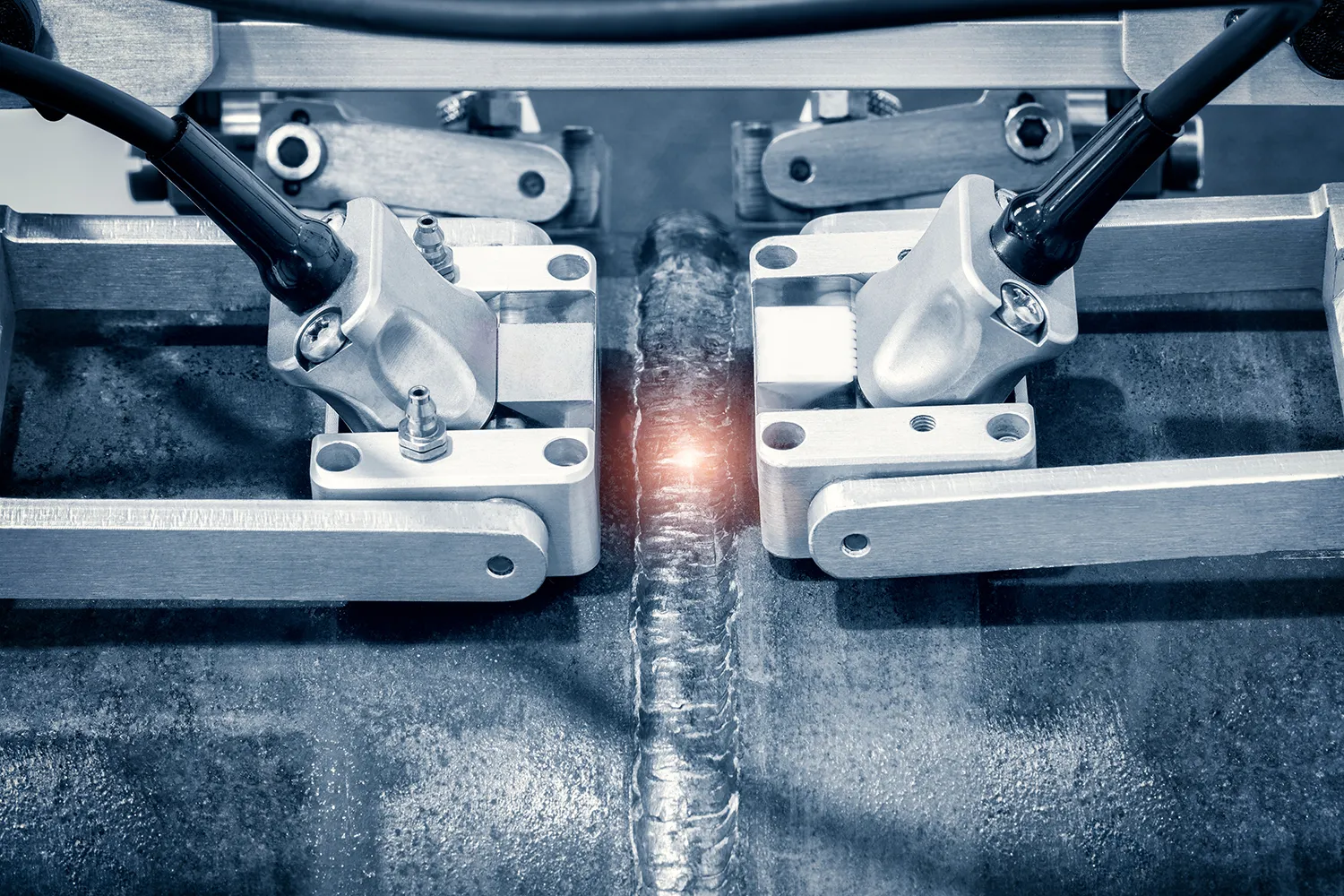

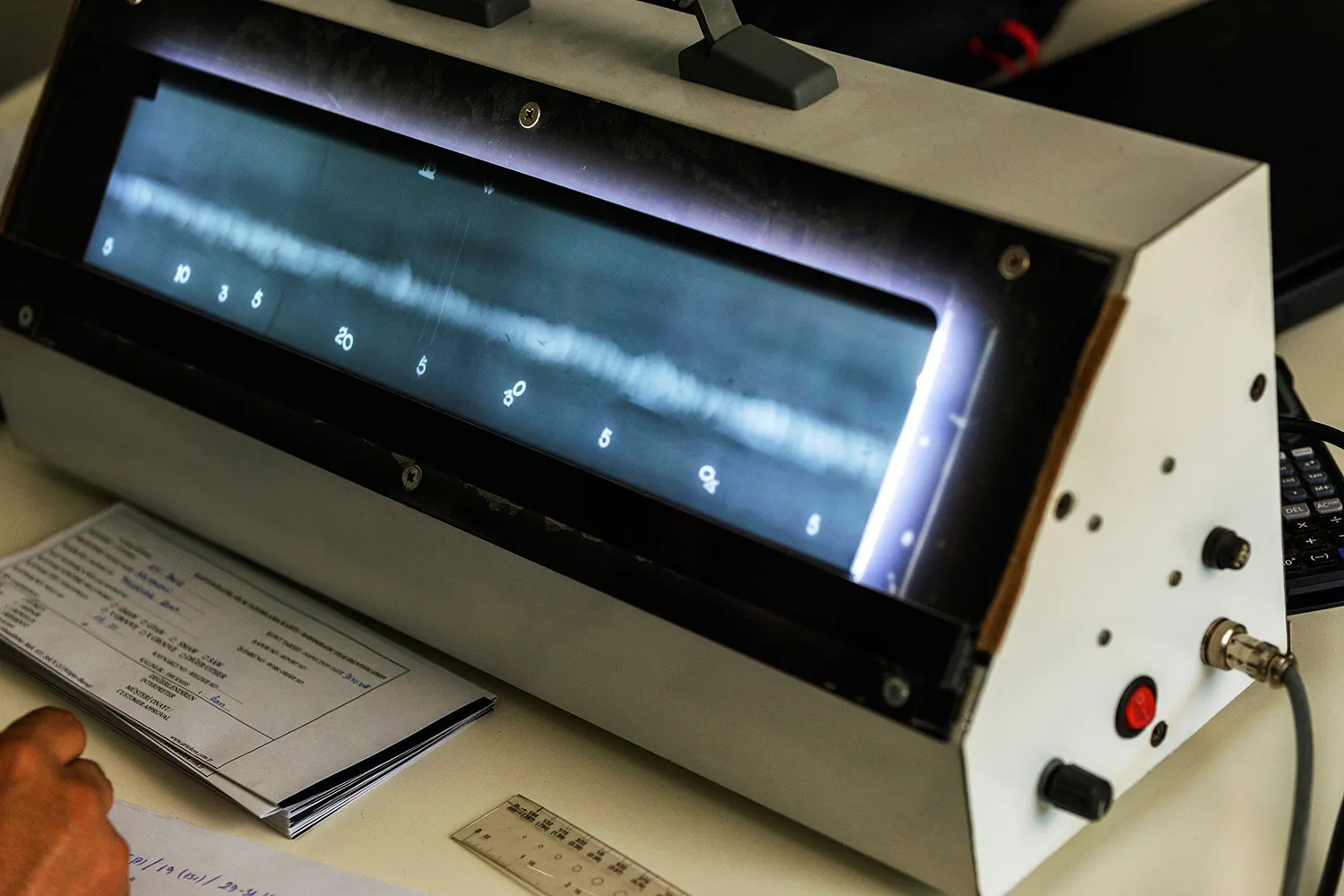

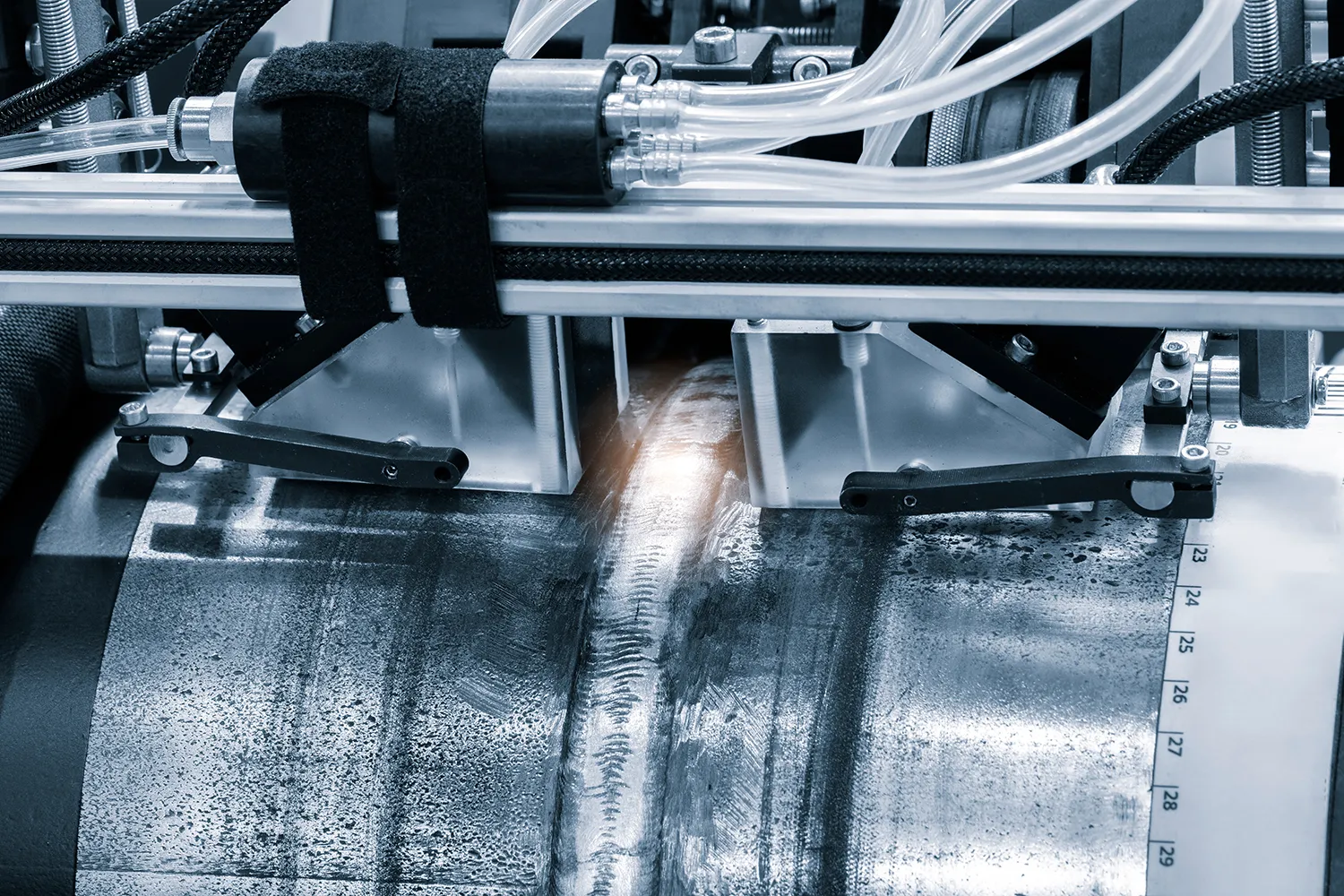

Developed within the framework of ITER—a 35-nation initiative to build the world’s first full-scale fusion reactor—the prototype system, called OORUK (Robotic Ultrasonic Inspection System), features an immersion bath, robotic manipulator, elevating table, and custom-built software. Jointly designed by TPU and NIIEFA, the software generates high-resolution 3D images, identifying structural defects down to a few microns.

The new platform eliminates manual labor and reduces preparation time from hours to minutes. The entire control cycle can now be executed by a single technician. The system has already passed a series of performance tests and is ready for deployment.

Fusion-Grade Quality Control with Export Potential

The stakes are high. ITER aims to become the world’s first sustainable fusion power plant, and its components must meet the most stringent international safety and performance standards. The vacuum chamber and magnetic assemblies must operate reliably under extreme thermal and electromagnetic stress.

Traditional inspection methods—particularly manual ultrasonic testing—are slow and labor-intensive. The robotic tomograph addresses this by offering automated, precision scanning, minimizing human error and enhancing safety. It complies with IAEA standards and supports Rosatom’s broader push for digitalized, high-accuracy monitoring.

The ultrasonic system captures detailed 3D models without requiring physical disassembly. It is driven by domestically developed software, capable of integration into Rosatom’s digital infrastructure.

This innovation has major export potential. BRICS nations such as China and India, along with Rosatom’s partners in Egypt and Turkey, have shown interest in adopting advanced NDT solutions for nuclear and scientific projects. Customized to meet international standards, the system could also be applied across the Asian and Middle Eastern energy sectors.

Domestically, the tomograph is suitable for use at nuclear power plants and in high-tech manufacturing—monitoring turbines, pipelines, and more. Future upgrades may include artificial intelligence to enhance automated defect recognition.

From Research to Market: Russia’s NDT Momentum

Russia has been steadily expanding its contribution to ITER since 2020, delivering superconducting and magnetic components. In 2023, NIIEFA built a prototype for the MITICA neutral beam injector. By 2025, it had developed a laser-based tomograph that significantly reduced inspection time.

While X-ray tomography

remains the standard in the U.S. and Europe, Russia’s ultrasonic solution

offers a compact, highly automated alternative. OORUK builds on TPU’s

long-standing expertise in radar systems, including the Radiodozor-M platform.

By 2027, Rosatom plans to scale this solution across additional facilities. By 2030, exports to BRICS countries are expected to become a reality—solidifying Russia’s role as a leader in the global NDT technology landscape.