Coal’s Digital Renaissance: How Algorithms and Automation Are Rewriting Russia’s Mining Future

In May 2025, Russia’s coal industry—supporting over 6.5 million people—entered a new phase. The transformation isn’t driven by picks and carts, but by algorithms, sensors, and digital twins.

A New Player Enters Old Mines

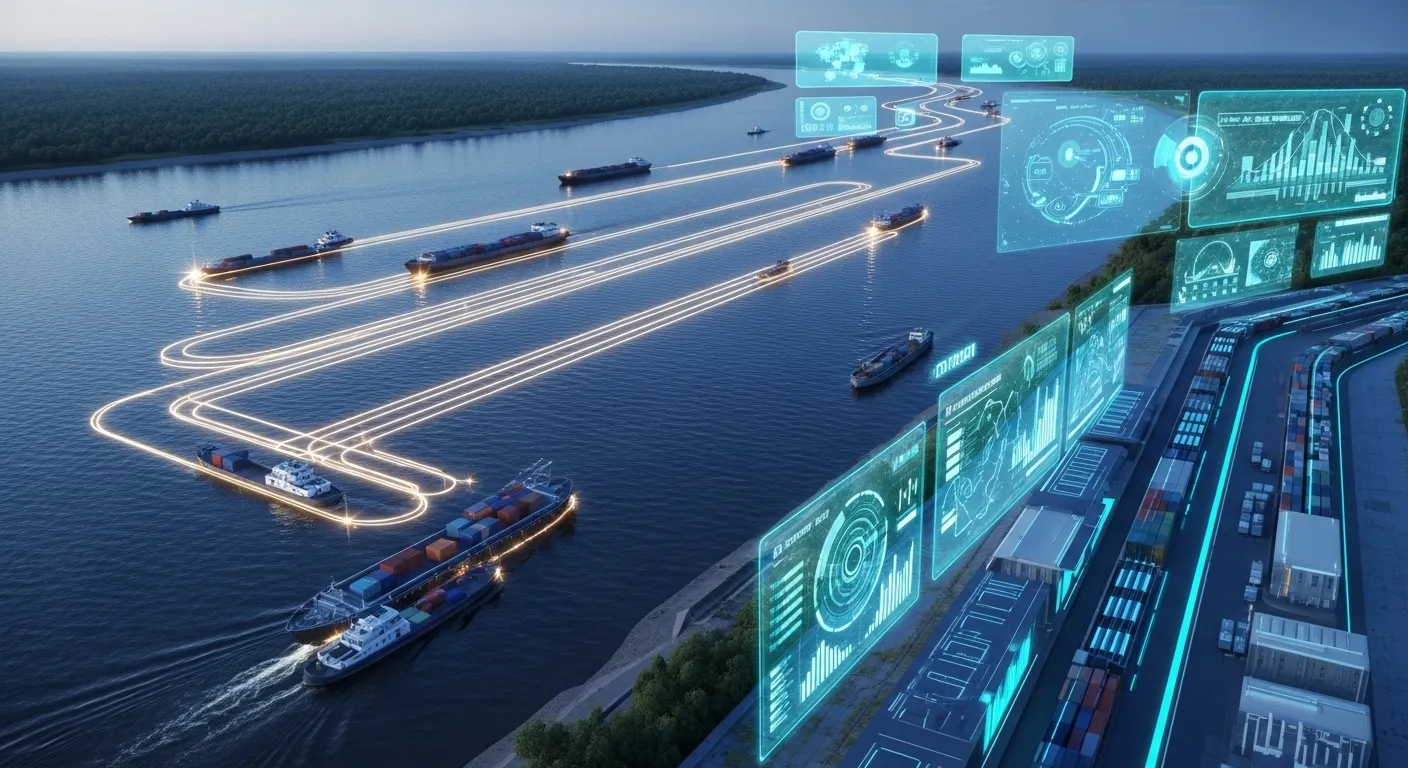

Coal remains a major economic engine for many Russian regions, accounting for 15% of national exports and supporting millions of stable jobs. Global demand, especially from the Asia-Pacific region, is climbing steadily, with 220 million metric tons exported in 2024 alone.

For Russia, this translates to protected incomes, secure jobs in mining towns, and critical foreign currency inflows. But the sector’s biggest disruptor today isn’t material—it’s IT engineering, now spearheading a full-scale digital overhaul.

Not a Gift, but a High-Tech Investment

Russia’s mining innovation is advancing along three key axes, all driven by digital technologies and showing clear results.

First, the export focus is shifting toward premium-grade coal. Innovations in enrichment have raised the share of high-calorific (6000+ kcal/kg), low-ash (<10%), and low-moisture (<15%) concentrate from 35% in 2021 to 50% in 2024.

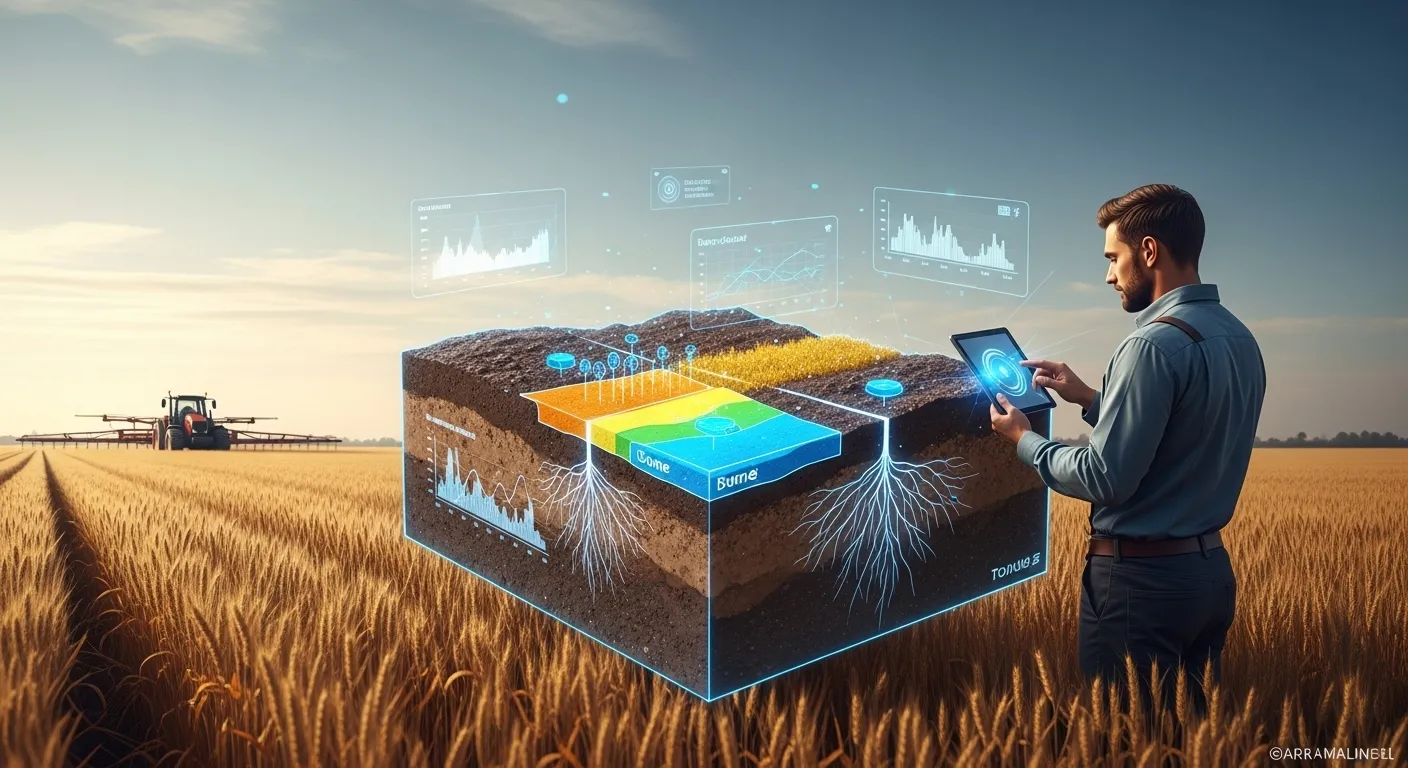

Second, import substitution is spawning a new export product—Russian mining engineering. Domestic platforms now manage extraction, logistics, and enrichment processes. AI-powered mining fleet systems have cut downtime by 22% and fuel use by 8%, while predictive analytics platforms have increased extraction yields by 1.5–3%—worth millions in added value for global clients.

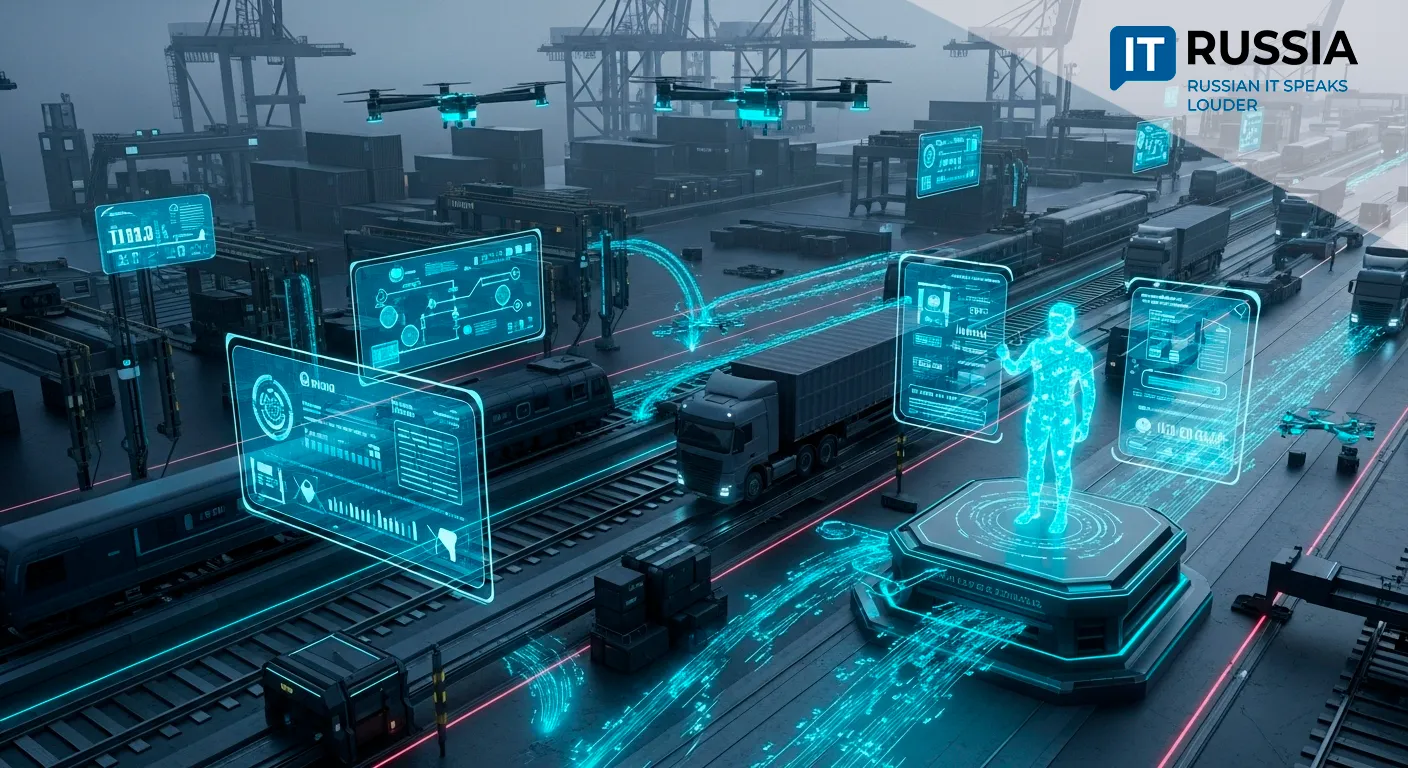

Third, automation is revolutionizing the labor landscape. Pilot programs using autonomous contactless mining have slashed costs by 17–25% (2021–2023). In line with Industry 5.0, robots handle dangerous tasks, while engineers manage operations via VR headsets and neural assistant systems. By 2027, up to 15,000 high-tech jobs are expected to emerge, replacing about 30,000 low-skill positions.

From Simulation to Reality

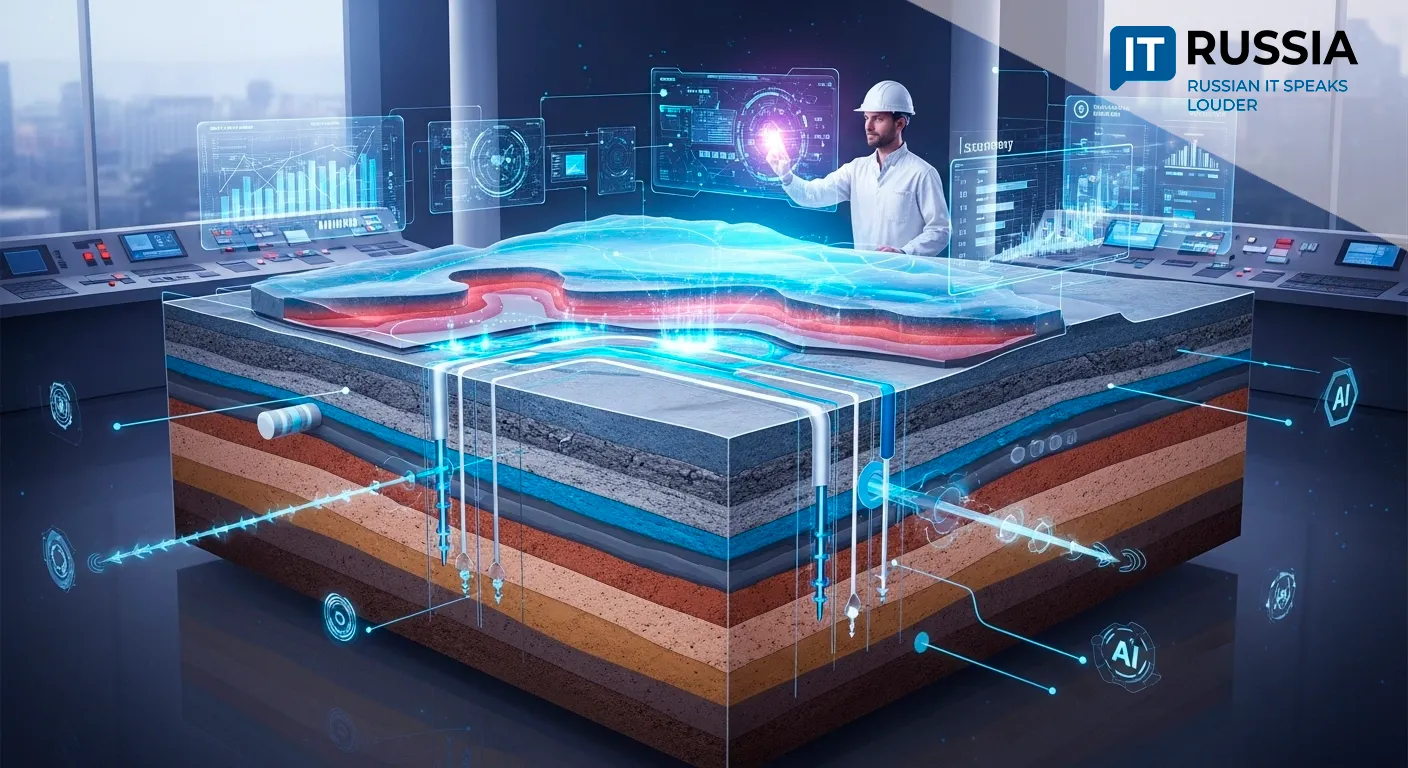

The shift began in 2021 with the development of domestic software for 3D deposit modeling and enrichment plant control. These early investments totaled 5 billion rubles.

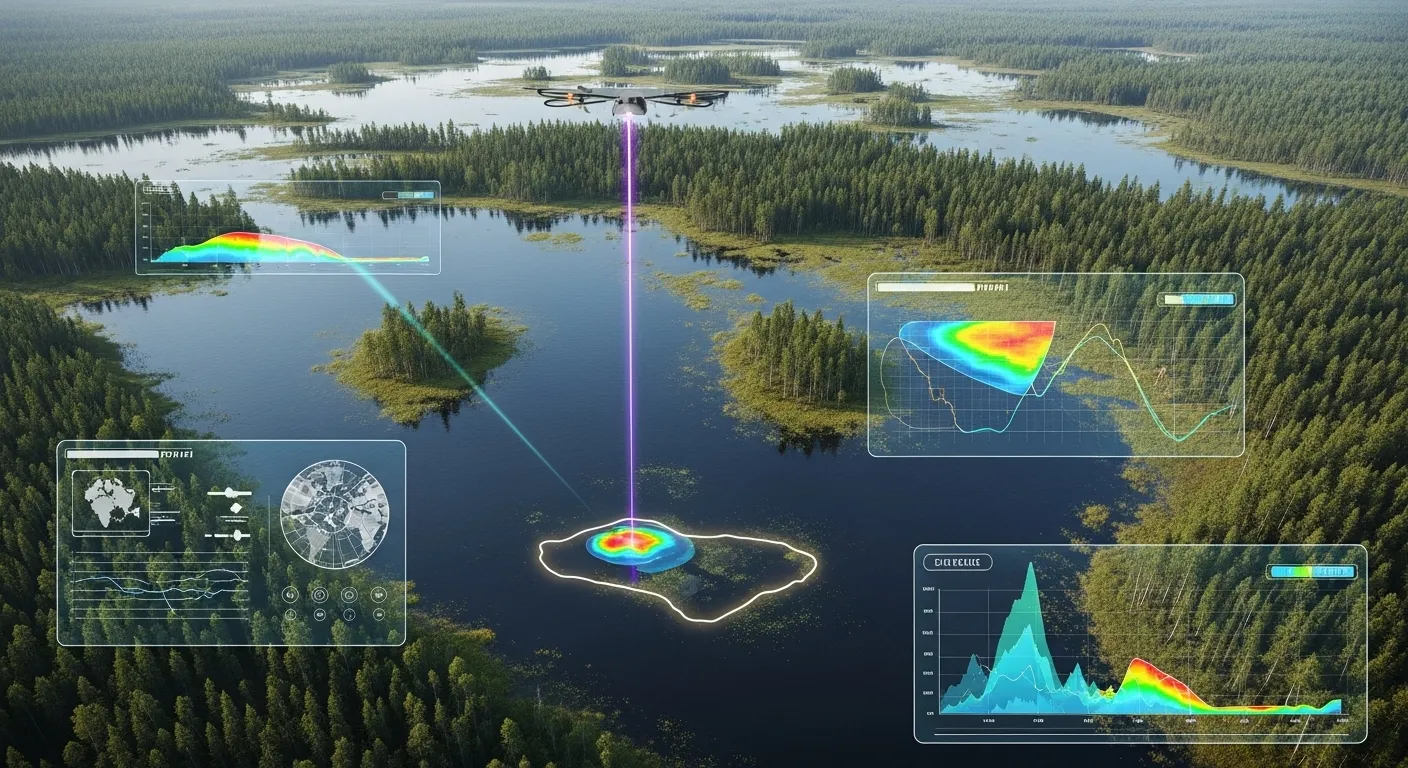

By 2023, AI was analyzing geological survey data, increasing forecasting accuracy by 30%. IoT platforms enabled real-time equipment monitoring, reducing unplanned repairs by 15%. Robotics kept workers out of harm’s way, cutting injuries by 40% in trial zones. The average cost reduction across automated operations reached 17%.

Recent focus has shifted to the human factor. Studies from HSE and MAI show 68% of mining engineers see digitalization as a tool for improving safety, while only 12% fear job loss. The concept of a 'digital miner'—a high-tech operator—is taking shape.

A Bold and Electrified Vision

TAPP Group, a Russian engineering firm, is proposing a radical idea: turning coal-rich regions like Kuzbass and Buryatia into digital hubs powered by local generation. Rather than ship raw material to ports, the energy would support AI infrastructure and cloud computing centers at the source—where power is cheap, land is abundant, and skilled labor already exists.

Path to a Digital Mining Economy

Success depends on three pillars: long-term state programs, compliance with global ESG trends, and alignment between technological and human capital development.

Government support will help solve cost-efficiency challenges. Investments in engineering are expected to reach $500 billion by 2027. Automation and digitalization are projected to boost productivity by 25–35% by 2030.

Russia’s coal sector stands at a transformative threshold. In the era ahead, coal won’t just burn—it will power the digital future.