Drilling Rigs in Russia’s Arctic Set to Shift to Automated Mode

Nornickel plans to move all drilling rigs in Talnakh to automated operation.

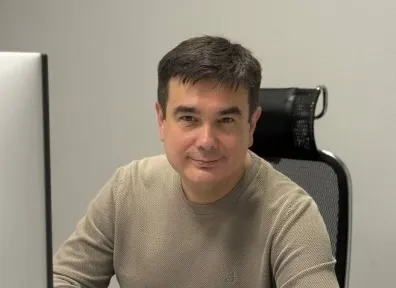

Nornickel, Russia’s leading mining and metals company and the world’s largest producer of high-grade nickel and palladium, plans to switch all drilling rigs in Talnakh, part of its Polar Division in the Arctic, to automated operation. The transition is scheduled to be completed in 2026, with some rigs already running in automated mode. The announcement was made by Alexander Leonov, vice president and head of the company’s Polar Division.

A Clear Timeline

According to Leonov, automating drilling first requires retrofitting the rigs themselves.

The company tested a domestically developed drilling automation system, Assistent Prokhodcheskogo Burenia (Assistant for Development Drilling), or APB, in October 2025. The system was trialed at the Oktyabrsky and Skalisty mines.

From Mine to Mill

Leonov said the company is also rolling out digital advisory tools for operators to help manage production processes.

At Nornickel’s facilities, artificial intelligence has also been integrated into flotation - the process of separating fine solid particles, mainly minerals, based on differences in their wettability. The AI monitors the process in real time, analyzes dozens of parameters, and adjusts settings on the fly to maximize metal recovery.

Earlier, we reported that Nornickel had upgraded its tailings storage monitoring system - critical and potentially hazardous facilities - using unmanned boats and drones.