GigaChat Goes Underground: Russian AI Powers Mining Equipment Monitoring

Russia's homegrown AI system, GigaChat, is being deployed to manage and optimize drilling operations at one of the country's major mining equipment factories.

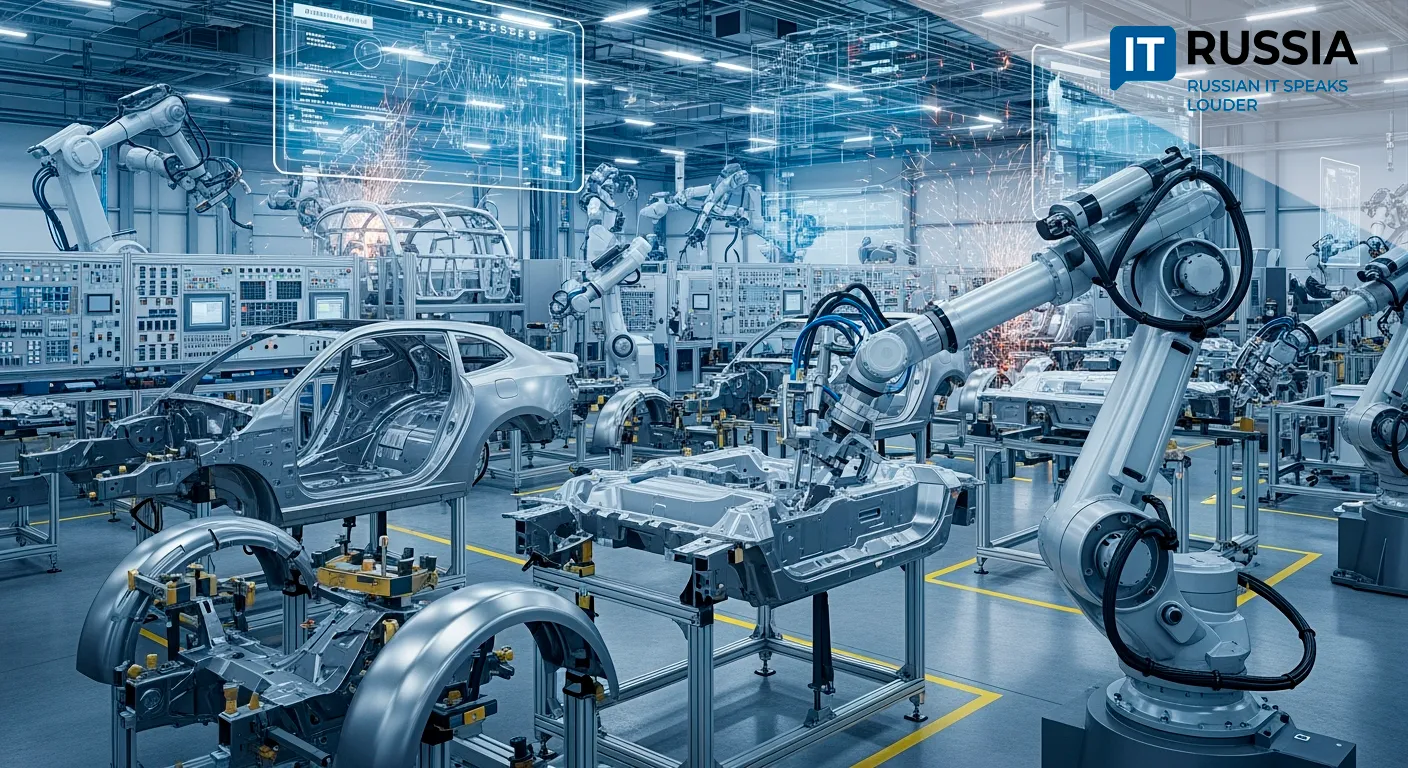

An Intelligent Hub for Heavy Industry

Founded in 1957, the Orenburg Drilling Equipment Plant (ZBO) has grown into one of Russia’s top exporters in the ferrous metallurgy sector. Its product line includes drill rods, casing pipes, and core drilling equipment—all subjected to high-frequency induction hardening for increased durability and coated for corrosion resistance.

Now, ZBO has embedded Sber’s AI platform, GigaChat, into its production line through a digital command center. The system processes sensor data in real time from key assets such as the ZBO S15E and ZBO S50 units. It also aggregates multimedia incident reports submitted via messenger by staff and service teams—eliminating the delays and clutter of traditional reporting systems.

GigaChat generates analytical summaries, flags anomalies, tracks compliance with service regulations, and automates maintenance alerts. The result is a digital nervous system that enhances responsiveness and situational awareness across the plant.

Delivering Results in the Field

Unlike lab prototypes, this is a real-world deployment of a Russian AI in a mission-critical industrial environment. According to ZBO personnel, the system has increased equipment uptime by more than 15%. In heavy industry, that figure directly correlates to profit, as each percentage point can represent millions saved in downtime and repair costs.

Safety has also improved. Automated compliance tracking and early issue detection reduce the likelihood of accidents and injuries—vital in mining operations where risks are ever-present. This deployment illustrates the operational maturity of Russian AI and its ability to manage complex industrial workflows.

Next-Gen Capabilities with GigaChat 2 Max

The integration of GigaChat into industrial processes paves the way for advanced applications like RAG systems and LangChain-based agents. Rather than merely notifying operators of faults, the AI can recommend repair strategies drawn from a vast case library.

The recently launched GigaChat 2 Max handles four times more context and delivers twice the accuracy. This unlocks new possibilities for predictive maintenance, big data analysis, and supply chain optimization.

Sber’s 'Research Assistant' tool, introduced at the 2025 SPIEF, equips engineers with data mining capabilities, automated report generation, and insights into hidden trends—key enablers for product development and process improvement.

From Proof-of-Concept to Industrial Deployment

ZBO’s success follows years of import substitution in Russia’s defense, energy, and mining sectors, and the localization of AI technologies such as NtechLab’s video surveillance systems.

Major firms like Yandex and Sber invested heavily in core AI infrastructure. In 2024, Sber and the AI Alliance launched open platforms for science and industry. ZBO’s use of GigaChat is a logical evolution—turning theory into functioning tools on production floors.

Russia is expected to see a rapid uptick in AI adoption across metallurgy, oil & gas, logistics, and power in the next year. Domestic AI could also become a bargaining chip in technology exports to allied countries.