Russia’s Robotics Industry Poised for Breakthrough

Russia is accelerating industrial robot adoption, building an autonomous robotics ecosystem amid shifting global supply chains.

Strategic Push for Robotics

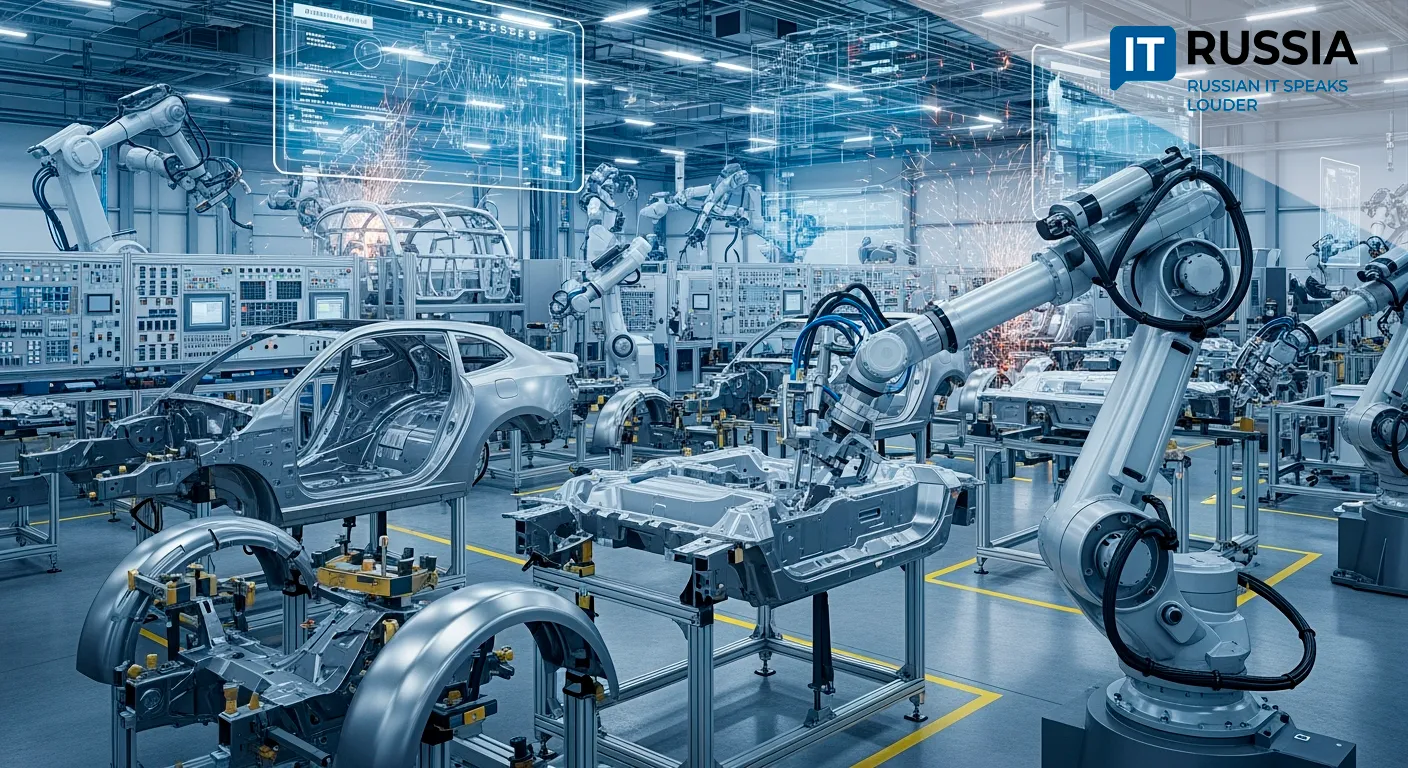

Russian industry and the fuel and energy sector are undergoing a sweeping transformation, driven by the adoption of robotic systems. This process gained momentum after 2022, when key Western robot suppliers—ABB, Fanuc, and Universal Robots—exited the Russian market, creating both a challenge and a strategic opening for domestic manufacturers.

Facing a shortage of skilled labor in critical industries like machinery, metallurgy, energy, and logistics, Russia has made robotics a strategic necessity. As of 2024, there were about 29 industrial robots per 10,000 employees in Russia—still far below the global average but signaling steady growth.

Declaring Technological Independence

Russia’s government and private sector have committed to a bold goal: joining the world’s top 25 nations in robot density by 2030—requiring a 14-fold increase. This initiative is being framed as a ‘technological declaration of independence.’

The energy sector alone plans to deploy at least 22,000 robots in the coming years, aiming for 145 robots per 10,000 workers. This effort is expected to boost both safety and productivity in hazardous environments.

Robots are particularly valuable where skilled labor is scarce. They take on repetitive, physically demanding, or dangerous tasks, freeing up humans for more complex roles and reducing operational costs.

State Support Driving Growth

Western vendors won’t find it easy to return. Since 2021–2022, Russia has launched subsidized lending programs with 1% interest rates for acquiring local robotic solutions. It has also established robotics R&D and education centers.

Thirty regional industrial robotics hubs are planned. The first opened in Tatarstan at Innopolis University, the second in Perm.

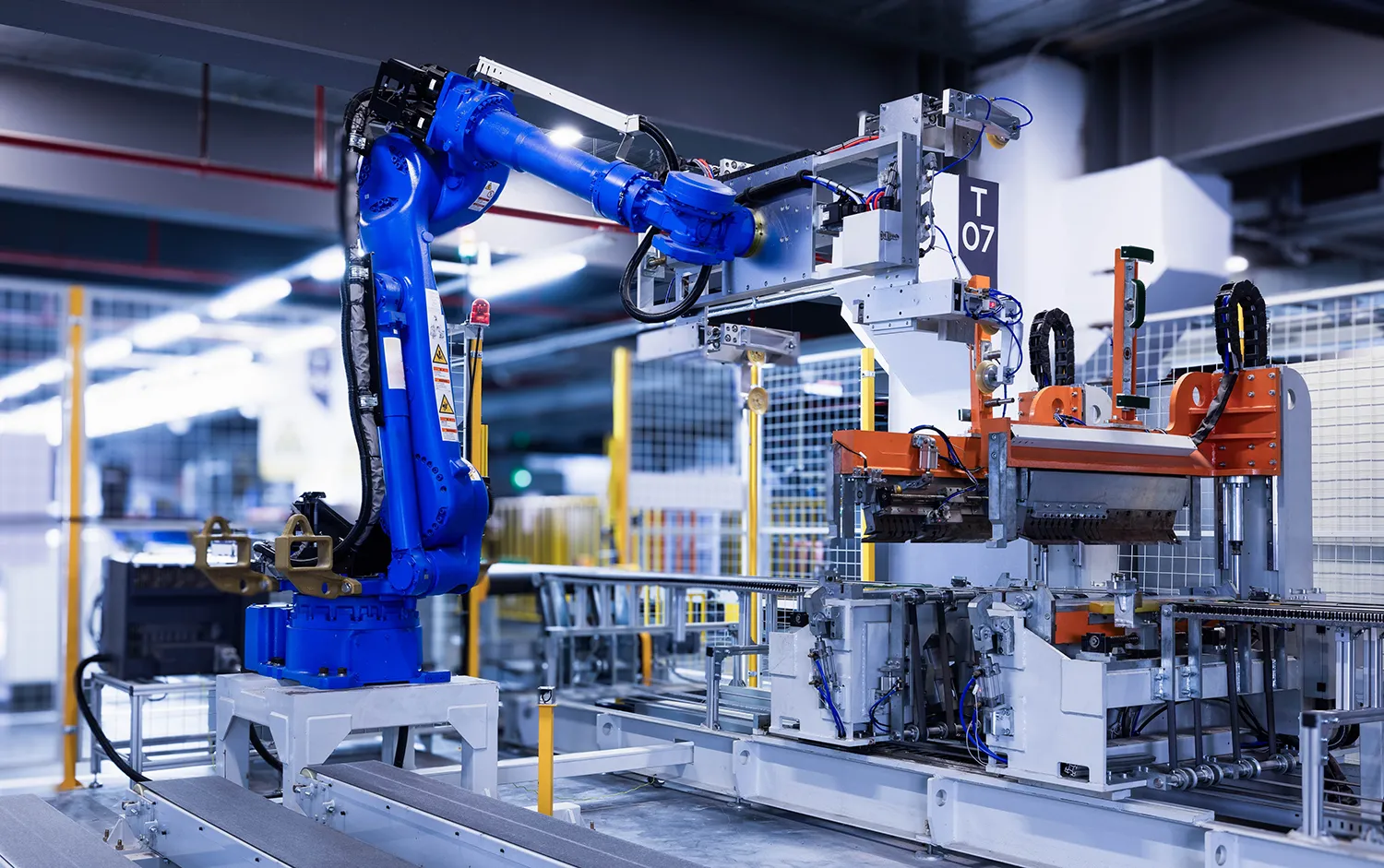

Russian manufacturers such as Corporation of Robots, Promobot, and TBot are expanding production, releasing new models, and tailoring solutions for local industries.

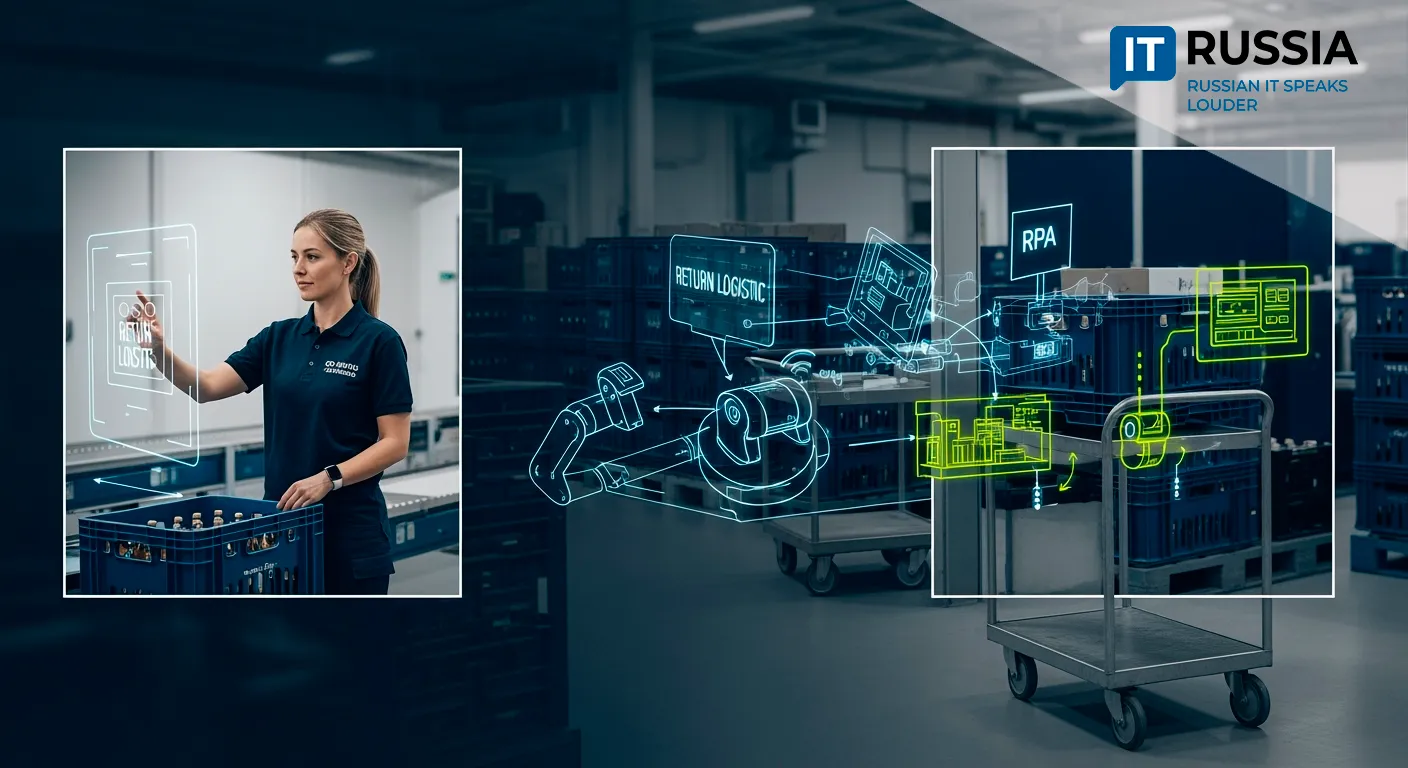

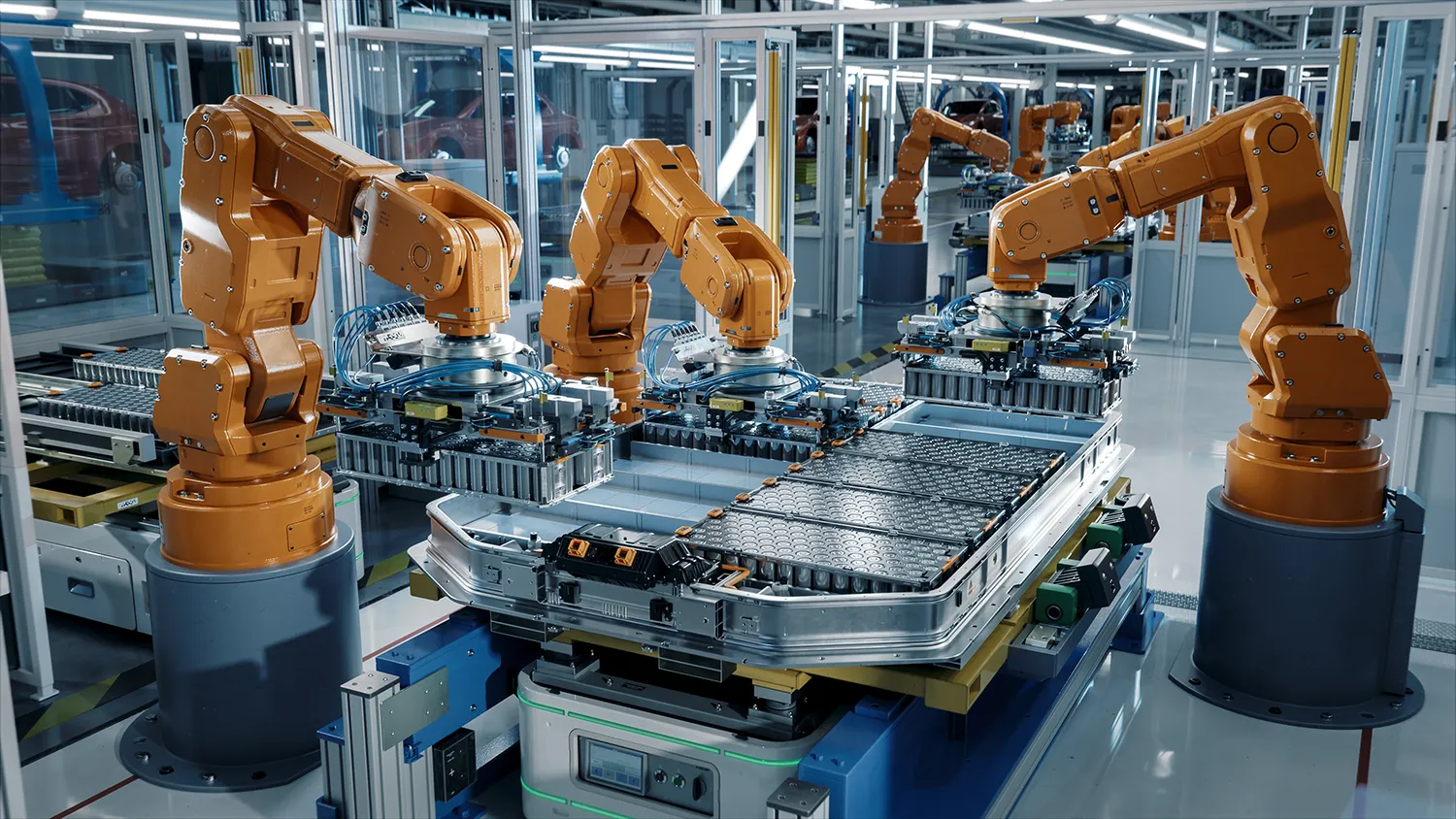

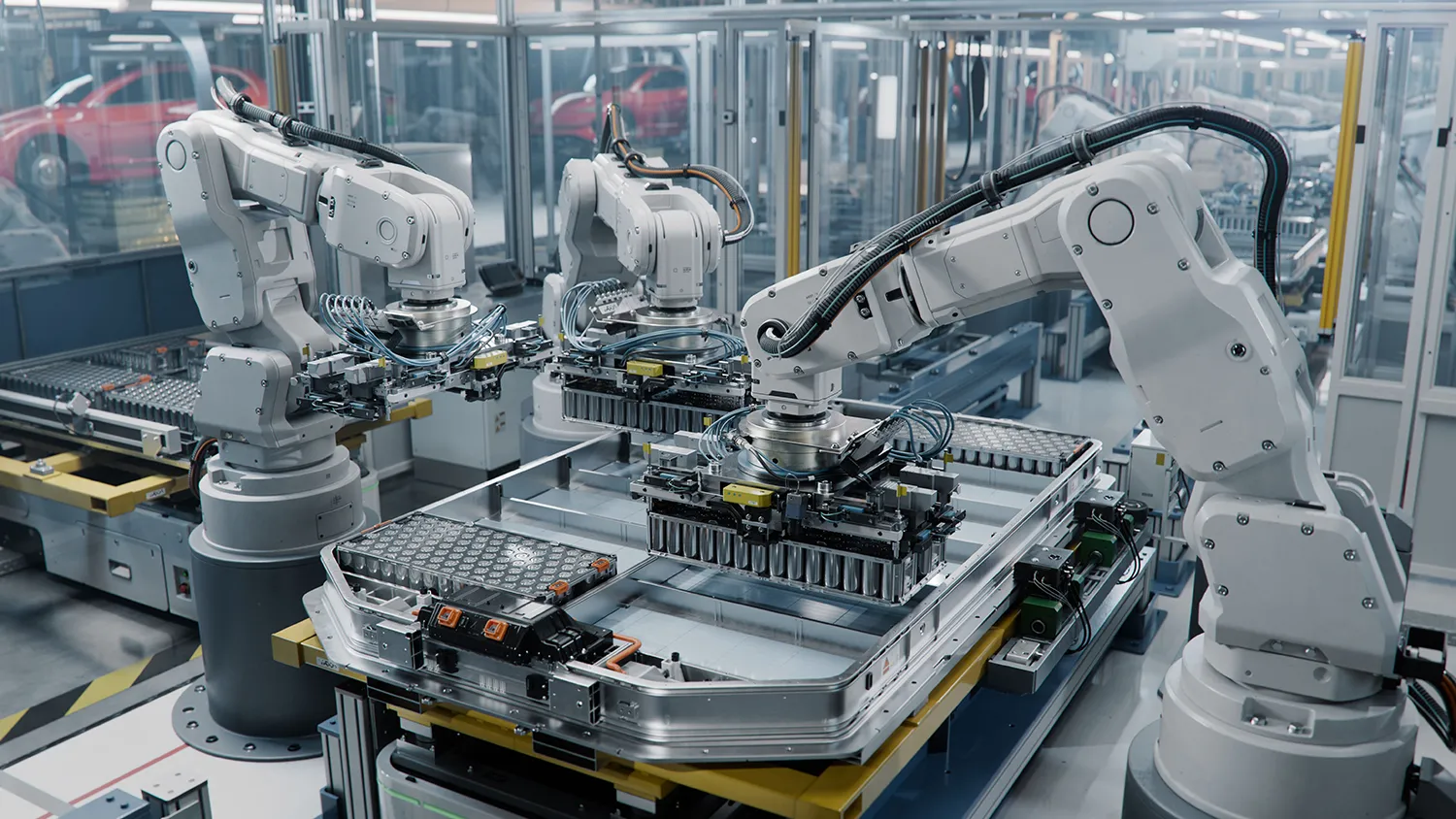

Autonomous mobile robots (AMRs) are gaining traction in warehouses and logistics. In manufacturing, robots are increasingly used for quality control, assembly, painting, and equipment servicing. In the energy sector, they’re deployed for diagnostics and maintenance of oil and gas infrastructure.

Momentum Builds Across Industries

The shift is underway: a mining robot was developed in Chelyabinsk, and Rosneft doubled production speed using Russian-made robotic manipulators.

In February 2025, automotive group Sollers launched a robotic engine production line. Agroholding Ruslakto has deployed robotic palletizing systems at its dairy plants.

AvtoVAZ commissioned a new Lada Iskra welding shop featuring 112 robots, capable of processing 30 car bodies per hour. ITELMA introduced specialized robotic systems for automotive electronics. Kaliningrad’s Avtotor began using a next-generation robotic line that speeds up welding fivefold.

These examples reflect the outcomes of Russia’s evolving industrial policy.

A Foundation for Sustainable Growth

The Ministry of Industry and Trade, in collaboration with Yandex and Sberbank, is developing a unified software standard for industrial robots.

While most technologies target domestic needs, there’s growing interest from CIS countries and developing economies facing similar labor shortages and import dependencies.

A successful robotics rollout will enhance Russia’s industrial competitiveness, lower costs, and shorten production cycles. The country is building ecosystems with R&D centers, test sites, joint IT platforms, and training programs—creating a launchpad for global expansion.

In this light, robotics is not just a reaction to external pressure but a long-term modernization strategy.