Russian AI Can Now Diagnose Robots and Recommend Repairs

Researchers in Sevastopol have developed new AI algorithms that detect malfunctions in robots by analyzing indirect signals in real time—without relying solely on sensor readings.

A research team at Sevastopol State University has created algorithms capable of identifying failures in robots based on indirect indicators. The system monitors a robot’s behavior in real time, detecting deviations even when direct measurements are unavailable or incomplete.

In modern robotic systems, sensors cannot measure every parameter directly, so diagnostics often require inference from limited data. The Sevastopol algorithms work much like a physician making a diagnosis by analyzing a combination of symptoms rather than a single one.

A Mathematical Model Behind the Diagnosis

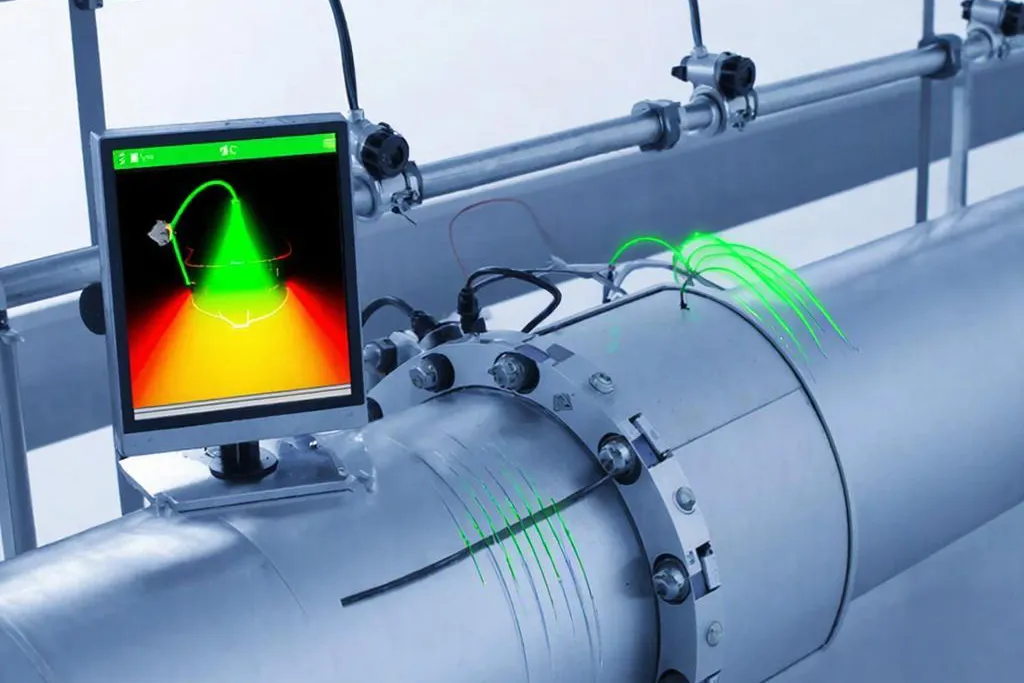

The team led by Alexey Kabanov developed a method that simplifies the robot’s complex mathematical model into a more tractable form. This model is used to build an observer—a computational module that compares actual sensor readings with how the robot should behave. When discrepancies grow, the observer pinpoints where the failure may be: in the actuators, sensors, mechanical components, or control system. This allows the system to detect problems long before they become critical.

Noise? No Problem.

The key advantage of the method is resistance to noise and imperfect sensor data. Real robotic systems always produce “dirty” signals—vibrations, temperature effects, and mechanical wear distort readings. Classical observers often fail under such conditions, as they assume perfect correspondence between the model and reality. The Sevastopol algorithms operate reliably even with modeling errors and avoid unstable switching modes, making them suitable for industrial controllers.

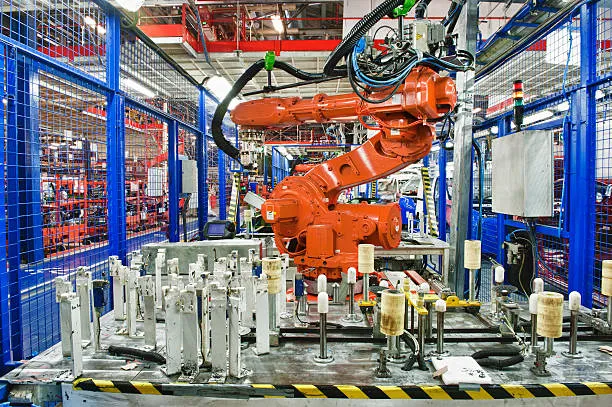

The new diagnostic techniques are especially useful for autonomous robots—inspection drones, industrial manipulators, and mobile infrastructure-maintenance robots. Early detection of anomalies ensures greater reliability and operational safety across the entire robotic system. The algorithms are now undergoing testing in preparation for industrial-scale deployment.