Russia Tests Modular Robot for Oil Pipeline Inspection and Repair

The Tubot system can clean, diagnose, and maintain pipelines—preventing leaks and saving millions in repairs.

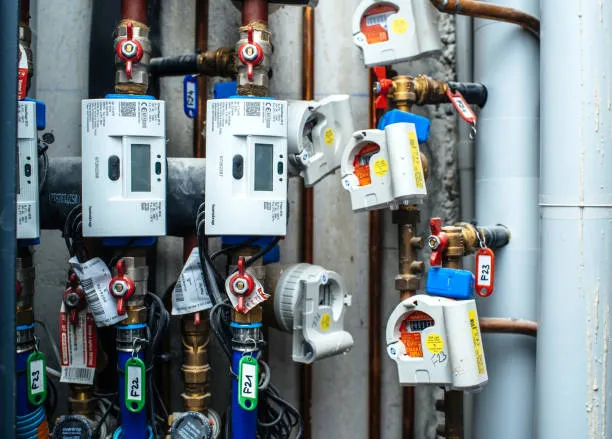

Russian engineers have successfully tested a modular robotic system designed to inspect, clean, and repair oil and gas pipelines. Developed by the startup Tubot, the robot has been trialed at Sibur facilities and a Yamal-Nenets oil field, proving its readiness for large-scale industrial use.

The robot’s key innovation lies in its modular design: it consists of detachable blocks that can be connected in different configurations. This allows operators to assemble robots of virtually any length and adapt them to pipelines of various diameters.

Preventing Accidents Before They Happen

The explosion-proof design of Tubot is critical for working safely in environments with flammable materials. The robot can be equipped with sensors, cameras, cleaning tools, and even devices for applying protective coatings inside the pipe.

According to the developers, using Tubot can cut pipeline repair costs by up to 80%, making it one of the most cost-effective innovations in industrial maintenance. Field tests in northern Russia and Bashkortostan confirmed the robot’s high traction power and its ability to tackle the most challenging internal contaminants.

The project underscores how AI and robotics are transforming Russia’s energy sector, improving safety, reducing environmental risks, and setting a new standard for smart industrial infrastructure.