In Russia Artificial Intelligence Gets a Job in Quality Control

An AI-based quality inspection system deployed at an industrial plant has taken over checks of assembly operations, detecting manufacturing defects with high accuracy.

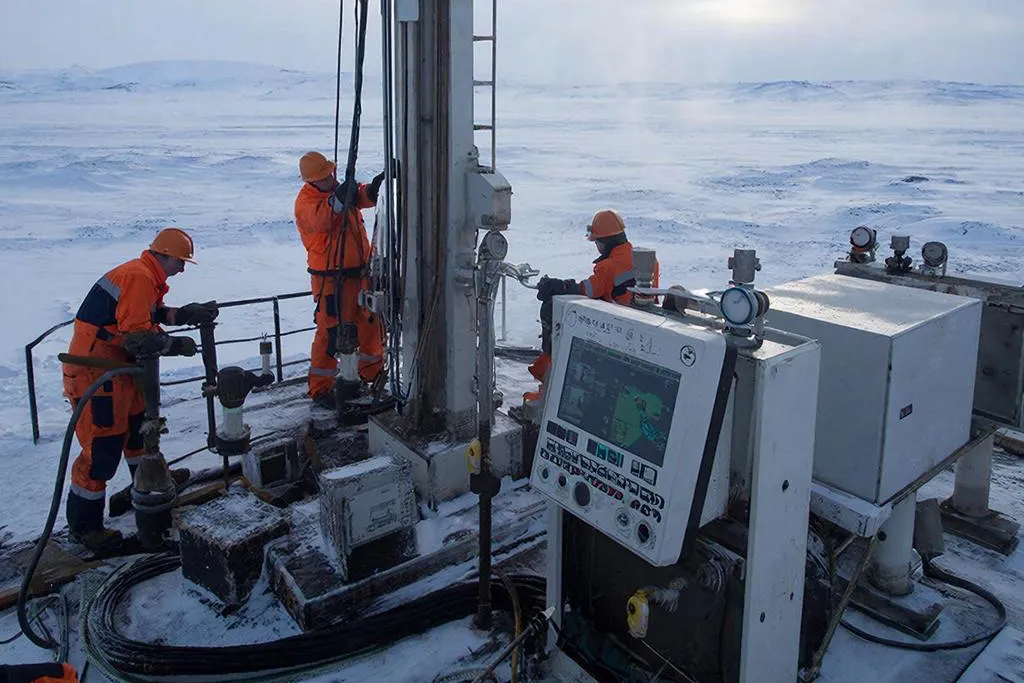

An AI-powered quality control system has been introduced at the METEOR Lift facility in St. Petersburg. For testing, the company selected a final assembly line for electronic modules. An intelligent camera-equipped unit was installed above the workstation, where it takes an image of the finished assembly and compares it with a reference model.

If the system detects deviations, it highlights the problematic area in the image, helping the operator quickly correct the error. This reduces the need for repeated inspections and saves working time, especially during periods of high workload.

Accuracy Will Improve

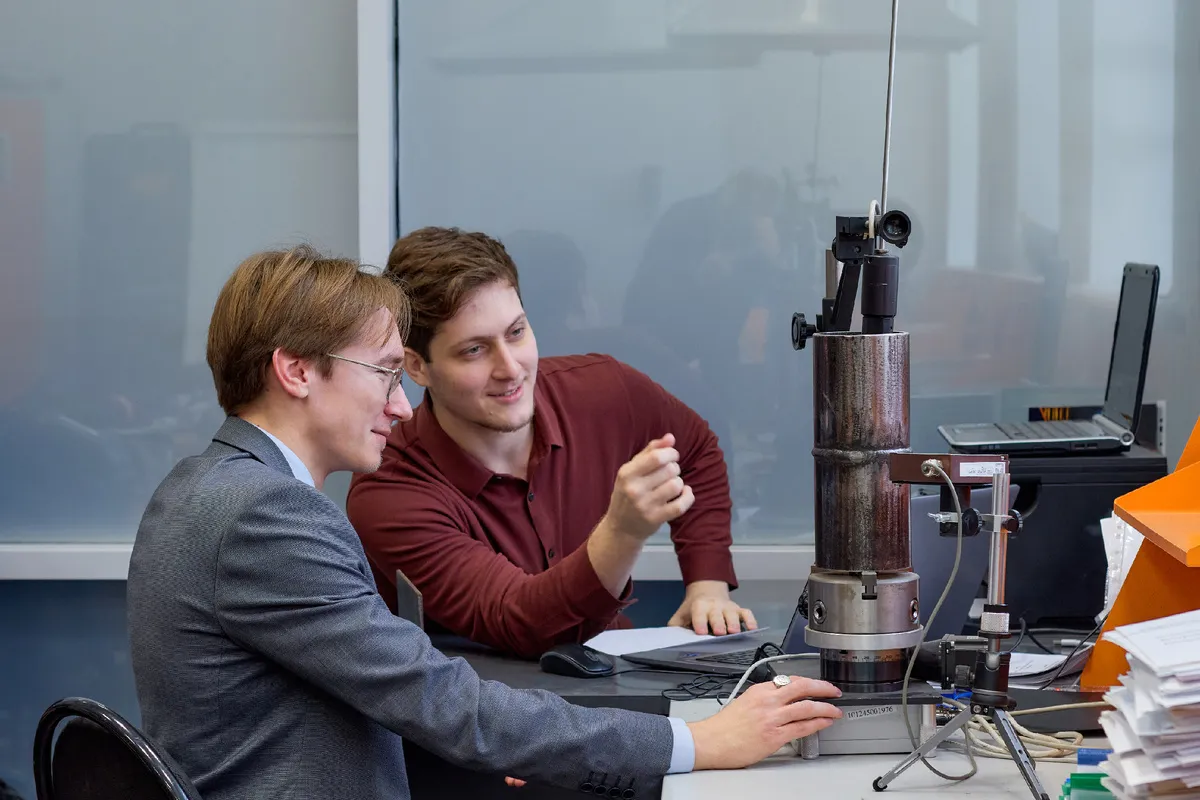

The technology is based on a trained neural network that analyzes hundreds of examples of both correct and incorrect assemblies. As more data is accumulated, recognition accuracy will continue to improve, allowing the system to identify a wider range of deviations. At the same time, the AI serves only as a support tool – the final quality assessment remains the responsibility of a human specialist.

No Threat to Jobs

METEOR Lift’s management emphasizes that the introduction of AI is aimed at boosting labor productivity and reducing errors without cutting staff. The system is being developed as part of the national “Labor Productivity” program and is expected to become a foundation for the broader rollout of digital technologies across the plant.

The deployment of this solution illustrates how modern IT tools are helping Russian manufacturers improve product quality and strengthen their capabilities in high-tech production.