IT Tools Become the “Circulatory System” of Industrial Production

EVRAZ has launched a real-time machine management system, marking another step in embedding digital tools directly into shop-floor operations.

+15% in Equipment Efficiency

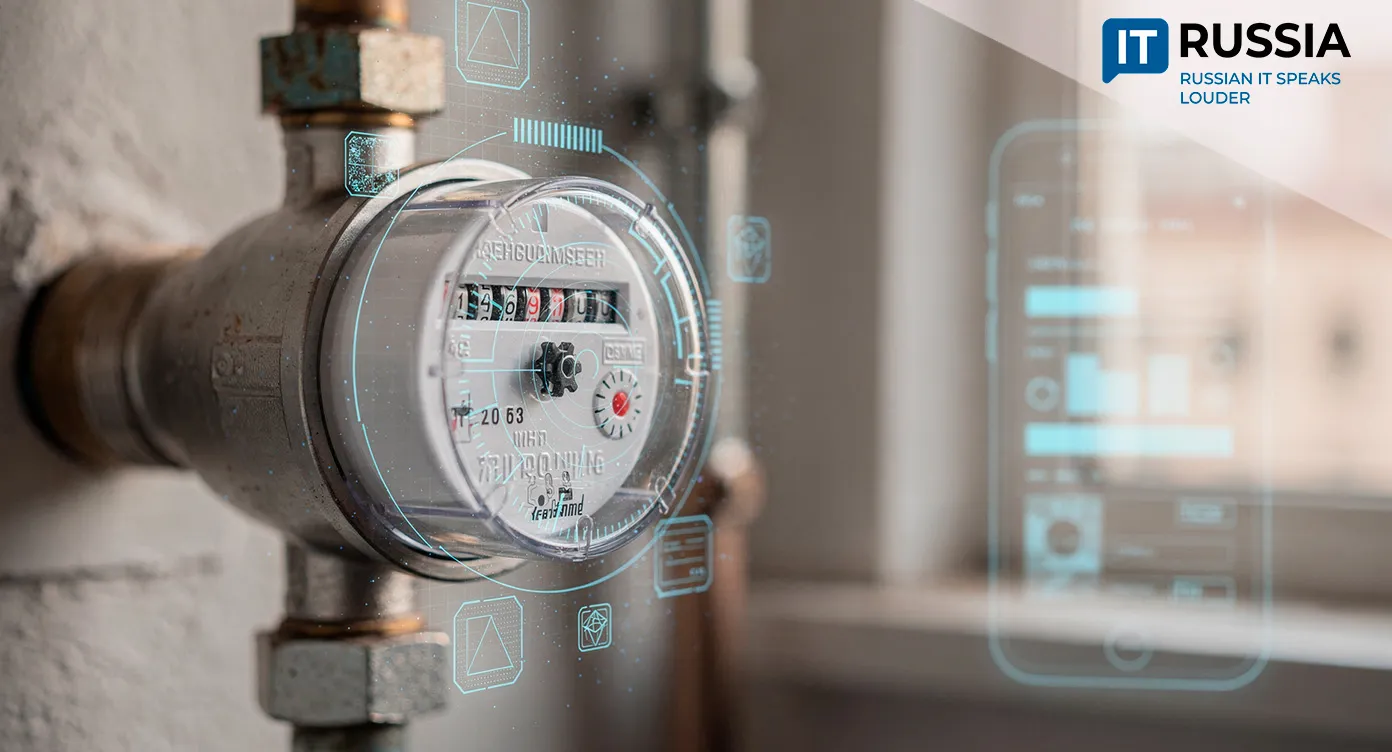

At the West Siberian Metallurgical Plant, part of EVRAZ ZSMK, the first phase of a digital equipment monitoring system has been completed in the mechanical shop. The new platform collects and analyzes key machine parameters in real time, including operating modes, downtime duration, utilization levels, and other production metrics. At this stage, 40 of the most heavily used machines have been integrated into the system. Plans call for connecting another 61 machines, extending coverage to a significant share of the shop’s equipment fleet.

The main outcome so far is a 15% increase in equipment utilization efficiency. The gain comes from faster identification of bottlenecks, reduced changeover time, and the elimination of so-called hidden losses – downtime that previously went unrecorded. Data is delivered through an intuitive visual interface accessible to everyone on the shop floor, from machine operators to senior management. This transparency allows decisions to be based on real-time analytics rather than subjective assessments.

EVRAZ ZSMK is one of Russia’s largest steel producers and the country’s dominant supplier of rail products, holding roughly 70% of the domestic market. The plant exports to around 30 countries worldwide.

MES and IIoT in Action

The project at EVRAZ ZSMK illustrates what modern industrial digital transformation looks like in practice. It is not about automating isolated tasks, but about integrating IT tools into everyday equipment operation. Real-time data collection and analysis – core elements of MES (Manufacturing Execution Systems), IIoT (Industrial Internet of Things), and BI platforms – are becoming the foundation for productivity gains and cost reduction at the level of a single shop.

The experience of the mechanical shop has already attracted interest from other machine-building divisions at ZSMK, where digitalization is expected to reduce costs and improve resource utilization.

Within the enterprise, there are plans to roll out the system to other production sites and integrate it with predictive maintenance modules and automated repair planning. Additional potential lies in applying machine learning to identify root causes of downtime and optimize work schedules.

For now, the solution remains local. Over time, however, it could have export potential. Similar systems are in demand at metallurgical and machinery plants abroad, opening opportunities for Russian IT firms specializing in industrial analytics.

From Point Solutions to a Digital DNA

Since 2017, EVRAZ has been systematically deploying digital solutions, including advanced analytics projects that deliver millions of dollars in annual savings. At other sites within the group, such as the Nizhny Tagil Metallurgical Plant, EVRAZ in 2023 partnered with the Russian firm Cifra to launch a unified, real-time production management system known as “Dispatcher.” The platform connected more than 160 machines into a single digital environment. Machine operators record job completion, the system tracks work-in-progress, downtime, and maintenance needs, and all operational data is available on screen. Paper drawings and process sheets have been replaced by digital workflows. The result has been more accurate utilization tracking, better quality control, shorter operation times, lower unit costs, and higher productivity.

Other digital initiatives are also underway. In 2025, EVRAZ ZSMK introduced a digital system for optimizing the cutting of OR65 switch rails on drilling and cutting machines. The system automatically calculates optimal cutting patterns while accounting for defects, increasing usable metal yield. One operator can now manage three machines from a single console, improving working conditions. Real-time data flows into the corporate network, providing quality control teams with live statistics on scrap and output. The technology increased the share of first-grade rails and shipment volumes. The economic impact over seven months of 2025 reached 9 million rubles ($116,000).

IT as the Backbone of Production

The new project at EVRAZ ZSMK is part of a broader, long-term digital strategy backed by measurable results. It shows how modern IT solutions are becoming an integral part of industrial production in Russia, delivering tangible efficiency gains even at the pilot stage. Over time, such systems are expected to form the backbone of unified enterprise digital platforms. Their wider adoption across the industry could accelerate the development of Russia’s industrial software market and improve its competitiveness internationally.