Flagship of Industry Digitalization: Smolensk NPP Awarded “Tsifrovoye PSR-Predpriyatie” Status

Smolensk Nuclear Power Plant has emerged as one of Rosatom’s digital frontrunners: the station has completed an industry-level audit of digital PSR exemplars, met all target benchmarks, and confirmed its status as a “Tsifrovoye PSR-Predpriyatie.”

What Was Assessed at Smolensk NPP

The plant underwent a final industry-wide quality audit of the digital transformation of the Production System Rosatom – PSR (lean production system). Experts from AO PSR, GK Greenatom, Tsifrum (private entity), and specialized divisions of AO Kontsern Rosenergoatom evaluated how digital tools are embedded into core operational processes: maintenance and repair, plant operation, logistics, and management.

In 2025, the station developed and digitized new PSR exemplars – improvement projects implemented using IT-based tools. The audit confirmed 100% compliance with mandatory benchmarks and more than 80% development maturity across the new digital exemplars, fully meeting industry requirements.

What the High Status Delivers

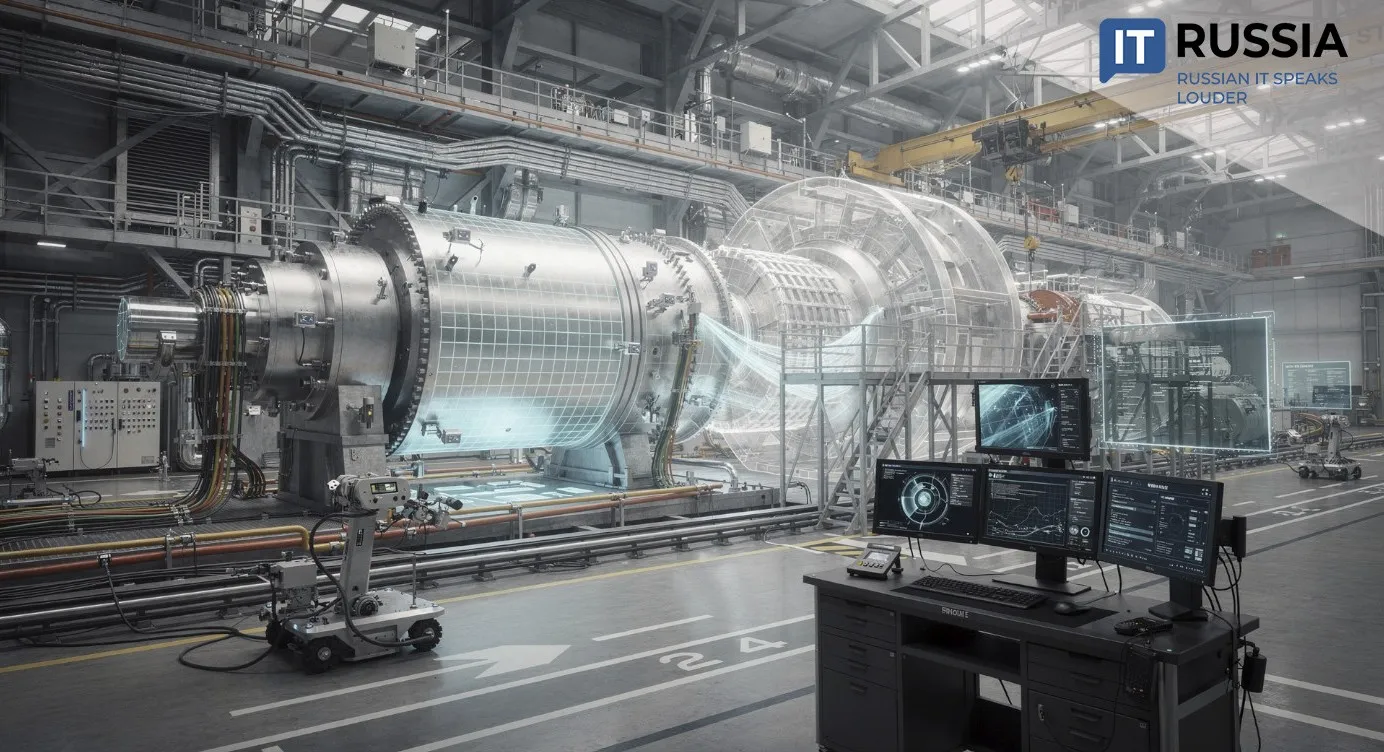

The status “Tsifrovoye PSR-Predpriyatie” reflects the depth of integration between lean production and digital technologies within day-to-day operations. Core planning, monitoring, maintenance and repair, equipment rounds, and warehouse logistics have been transitioned into a unified digital environment. Decisions on safety, reliability, and efficiency are made using data streams operating close to real time. Personnel rely on digital inspection routes, electronic equipment passports, and data dashboards instead of paper documentation.

For the surrounding region, this translates into more reliable power supply and reduced risk of outages. For the nuclear sector, it establishes a reference site from which digital practices can be replicated across other nuclear power plants.

How Digital PSR Is Transforming NPP Operations

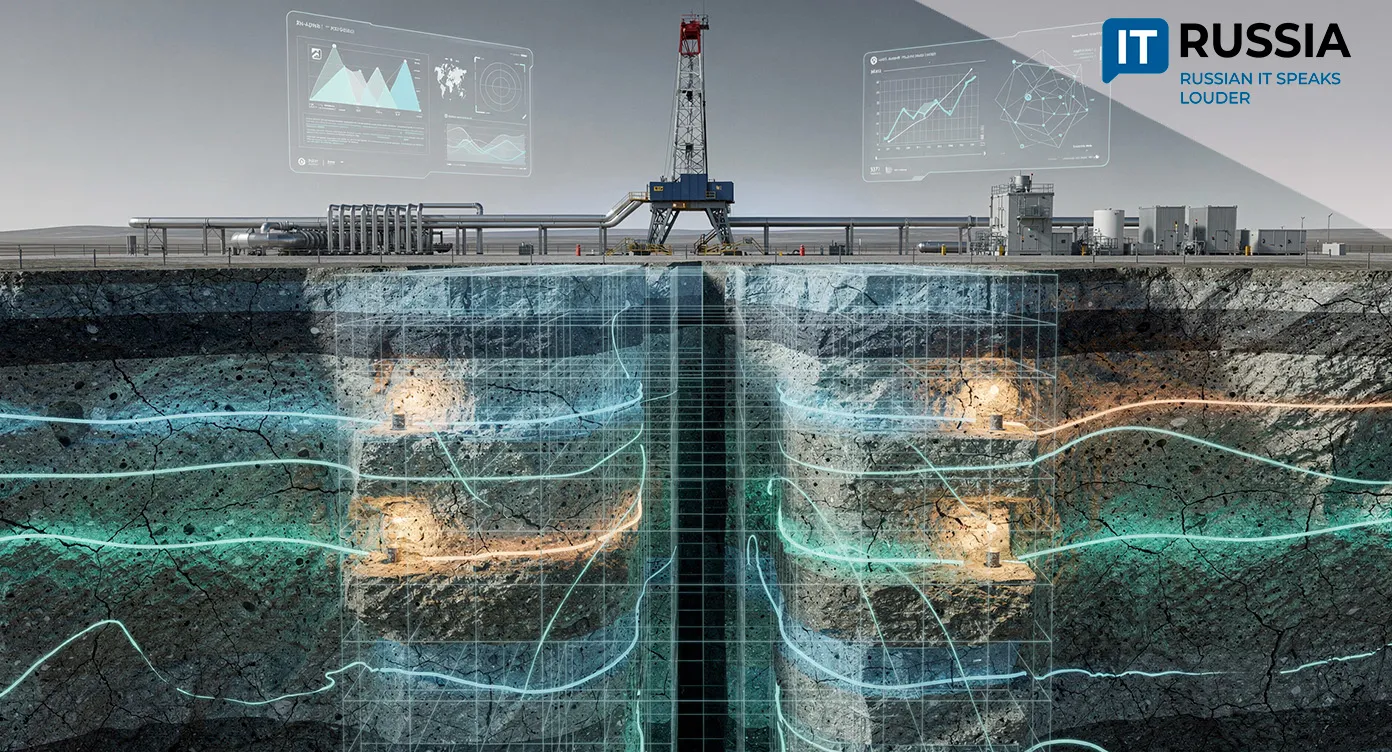

PSR within Rosatom was initially designed as a continuous improvement and lean manufacturing framework. Today it increasingly rests on digital foundations: sensors, monitoring systems, digital twins, and analytical platforms. At stations such as Smolensk and Beloyarsk, digital PSR exemplars already include modules such as

- “Operativnoye Upravleniye Ekspluatatsiyey Energobloka. Obkhody Oborudovaniya” (Operational Management of Power Unit Operation. Equipment Inspections),

- “Upravleniye Dopuskami Personala Dlya Vypolneniya Rabot” (Personnel Work Permit Management), and

- “Pasportizatsiya Bazy Oborudovaniya” (Equipment Database Certification).

Equipment rounds are conducted using information systems that record component condition and automatically generate maintenance requests. This shortens response times to deviations, reduces manual workload, and improves the quality of operational data on which plant management decisions depend.

Within the Framework of Industry Leadership

Smolensk NPP has already entered Rosatom’s top three PSR leaders and in 2025 received the bronze-level “Tsifrovoye PSR-Predpriyatie” designation. The current audit shows the plant is not merely maintaining its position but deepening its digital transformation: new PSR projects have been formally validated, digital tools have been expanded across operations and maintenance, and IT infrastructure has been strengthened.

In the coming years, Smolensk NPP plans to further extend best practices in digitalization – expanding electronic inspection routes, increasing the number of information terminals in workshops, and launching additional digital initiatives in warehouse operations and corporate functions. The station is consolidating its role as a pilot site where digital solutions are refined before scaling across additional power units.