AI on Quality Patrol: Computer Vision Flags Defects in Nuclear Components

At the Mayak Production Association in Chelyabinsk region, artificial intelligence has begun replacing human inspectors in quality control. The system identifies microscopic defects in seconds – a task beyond the limits of the naked eye.

First Steps

A pilot project incorporating artificial intelligence elements was launched in 2020 at Mayak Production Association, part of Rosatom and located in the closed city of Ozersk in Chelyabinsk region. The first computer vision deployment was introduced within the supply department to control the distribution of preventive nutrition to employees.

The system relies on biometric identification linked to personal ID cards: a camera captures an employee’s face and matches it against records in the database. This eliminates the possibility of using another person’s card and ensures that meals are issued only to authorized staff.

Biometrics Without Error

The biometric system identifies employees with 99.9% accuracy. The algorithm accounts for facial features even when lighting conditions change or appearance shifts slightly – for example, when a person wears glasses or changes hairstyle.

The technology was tested in real production conditions and demonstrated operational reliability. It now functions continuously in cafeterias and meal distribution points across the facility. That initial rollout laid the groundwork for more ambitious AI initiatives at Mayak.

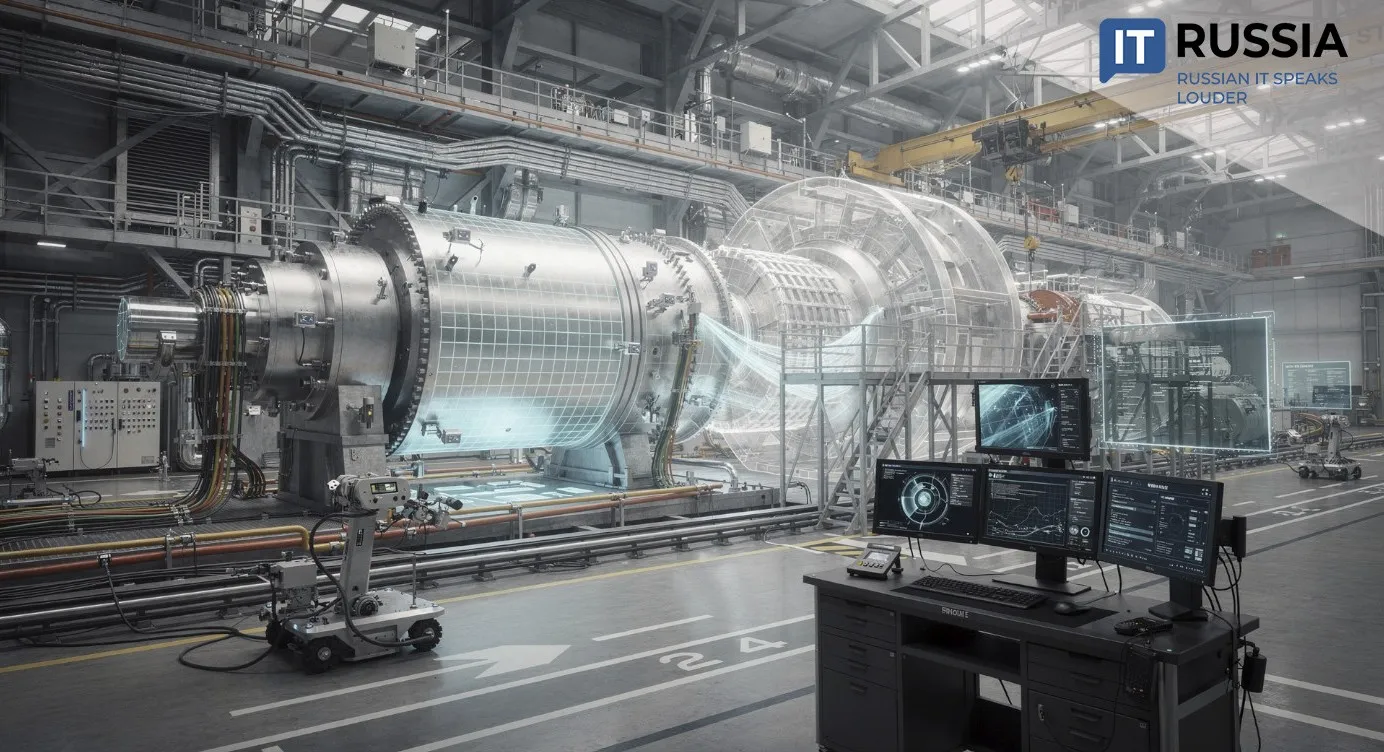

Computer Vision on the Production Floor

The next phase introduced the “Iskusstvenny Intellekt na Sluzhbe Kontrolya Kachestva” (Artificial Intelligence in Quality Control) system at Mayak’s Instrument-Mechanical Plant. The facility manufactures precision components for the nuclear industry, where even a microscopic scratch is unacceptable for safety reasons and quality standards are uncompromising.

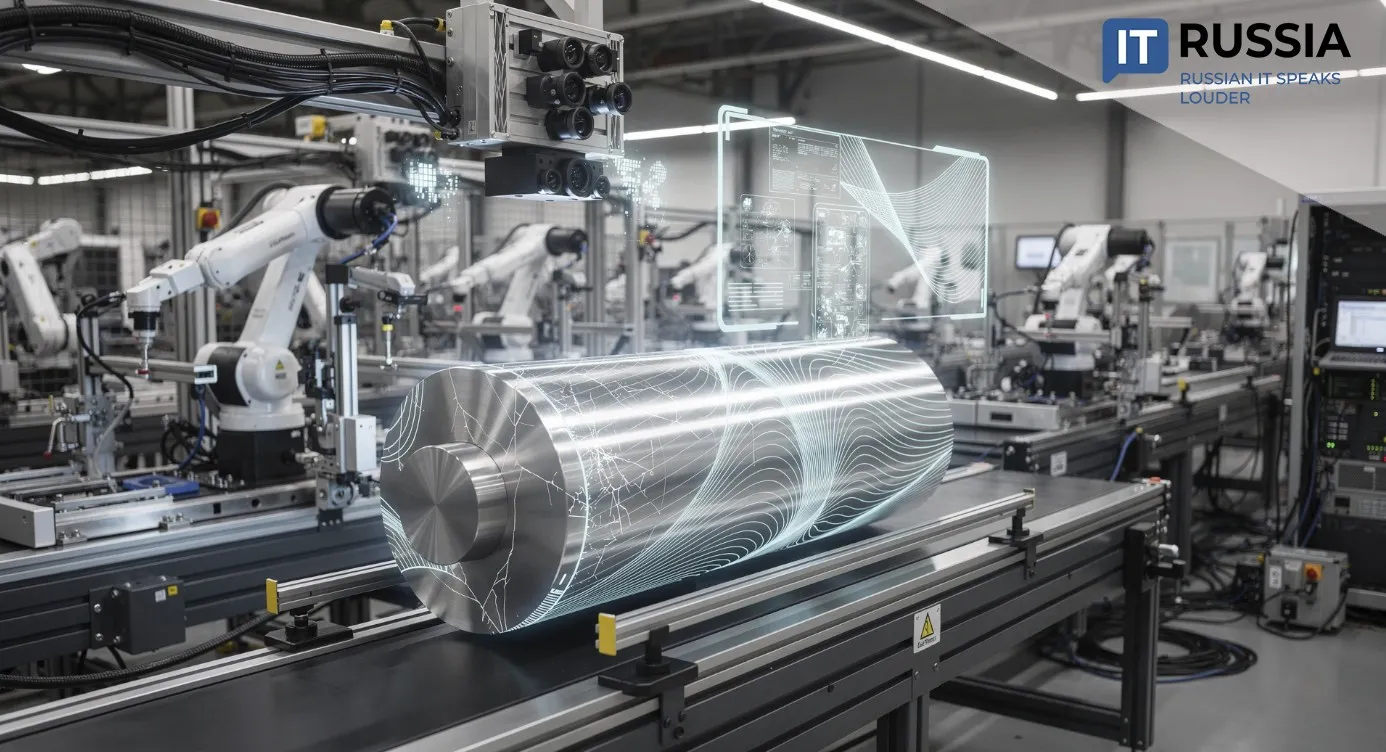

Engineers trained the neural network using thousands of images of parts with and without defects. The system learned to recognize deviations based on predefined parameters. Cameras now scan every component moving along the production line, and the algorithm instantly determines whether the part meets specifications or must be rejected.

Speed and Precision at Scale

The new system operates hundreds of times faster and more thoroughly than a human inspector. A check that previously required several minutes is now completed in fractions of a second. At the same time, the AI detects defects smaller than 0.1 millimeters – scratches and microcracks invisible without magnification tools.

In nuclear manufacturing, where each component directly affects operational safety, this level of precision is critical. Automated inspection reduces human-factor risks and strengthens reliability across the production chain.

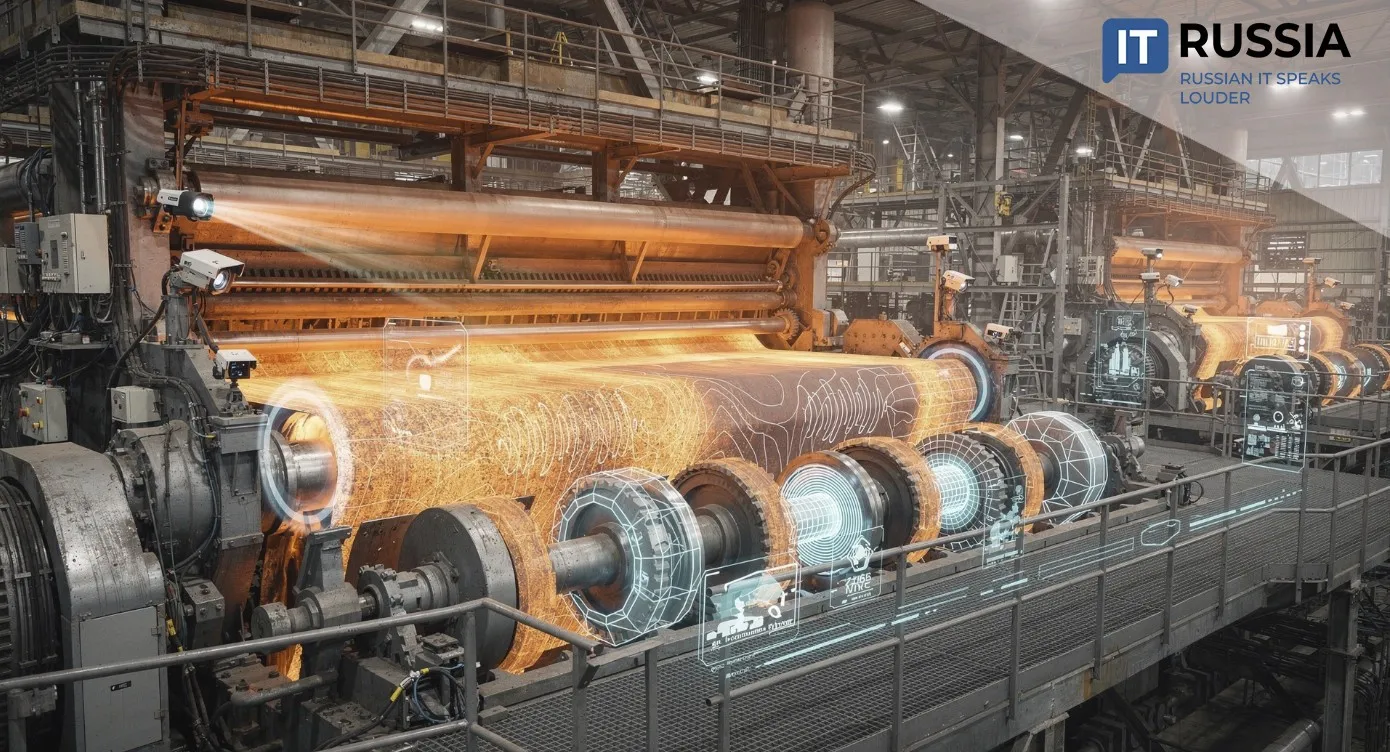

From Prototype to Industrial Deployment

The AI systems at Mayak are currently in pilot industrial operation. After completing testing and certification, the company plans to roll them out as standardized solutions across additional production sites.

The projects have already received industry recognition. They were nominated for Rosatom’s “Digital and IT Leaders of the Nuclear Industry” award, signaling that Mayak’s developments align with the corporation’s digital transformation benchmarks.

Experience for the Entire Sector

The computer vision technologies validated at Mayak can be adapted for other nuclear facilities and, more broadly, for critical manufacturing sectors. Quality control solutions of this kind are particularly in demand in high-tech production environments where absolute precision and complete confidence in component integrity are mandatory.

Russian engineers are demonstrating the capacity to build industrial AI systems for complex manufacturing tasks on a domestic scientific and technological foundation, including for some of the most demanding sectors of critical industry.