Digital Tools Boost Repair Efficiency at Khiagda’s Mining Operations

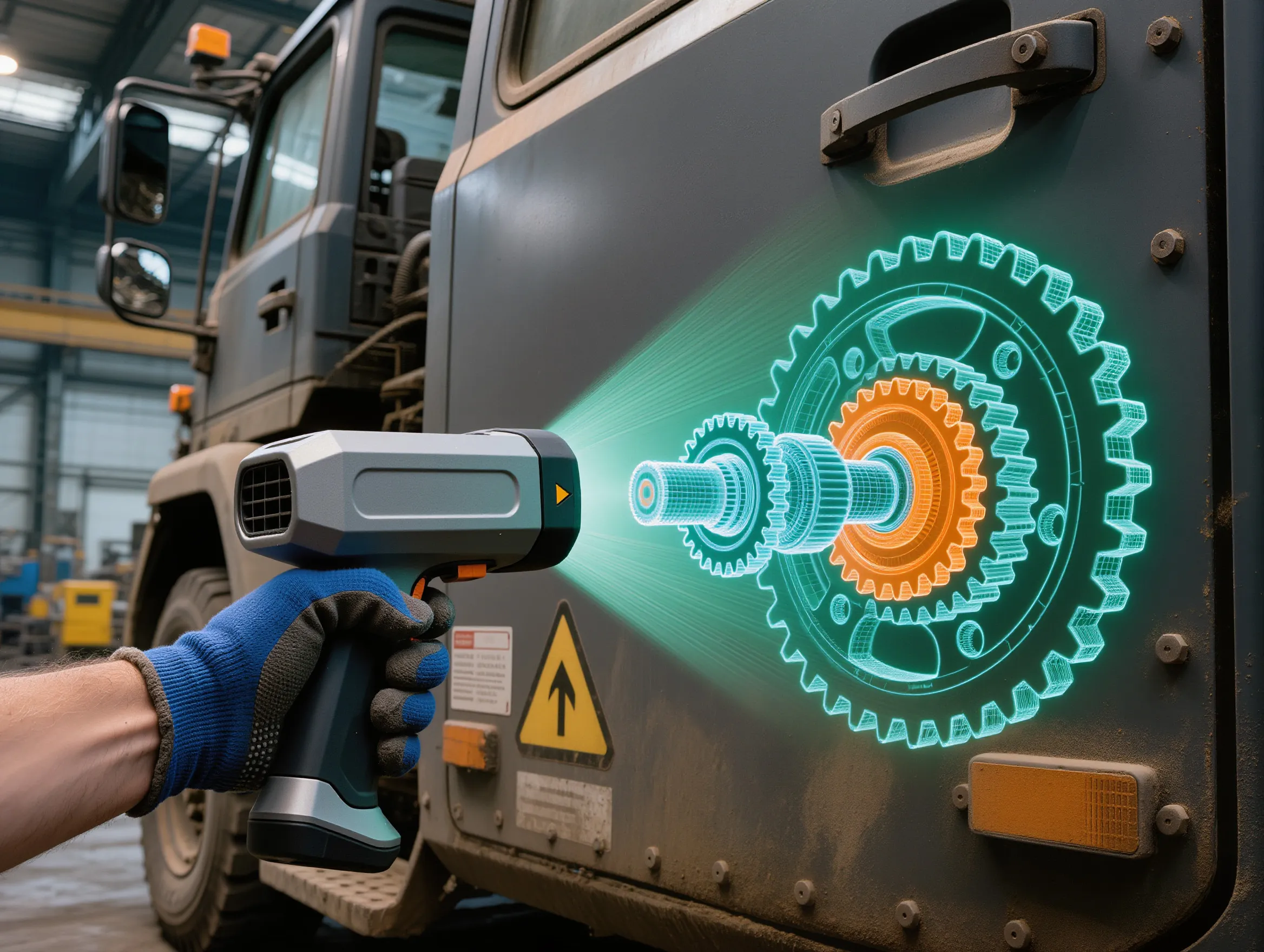

Khiagda, a subsidiary of Rosatom’s Mining Division, is introducing an innovative multi-brand diagnostic scanner to increase the efficiency of repairing vehicles and specialized machinery at its production base.

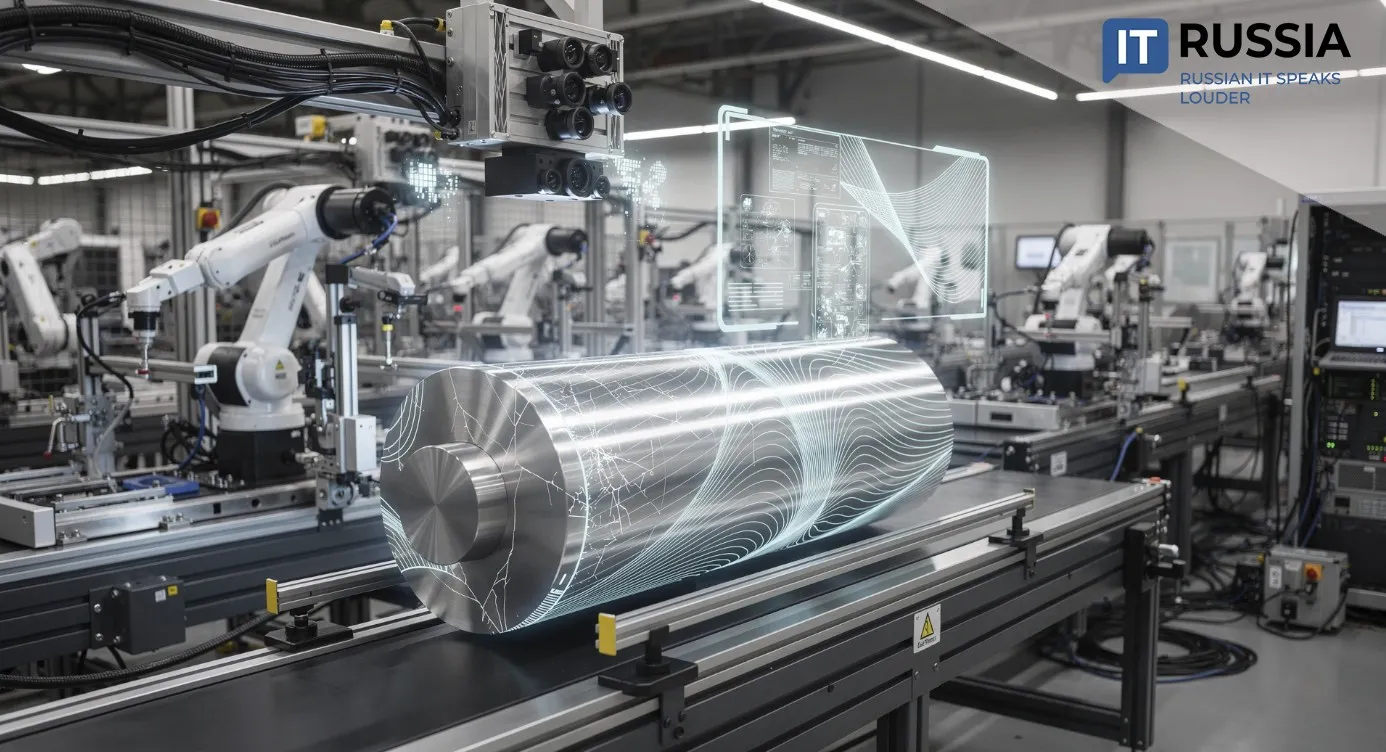

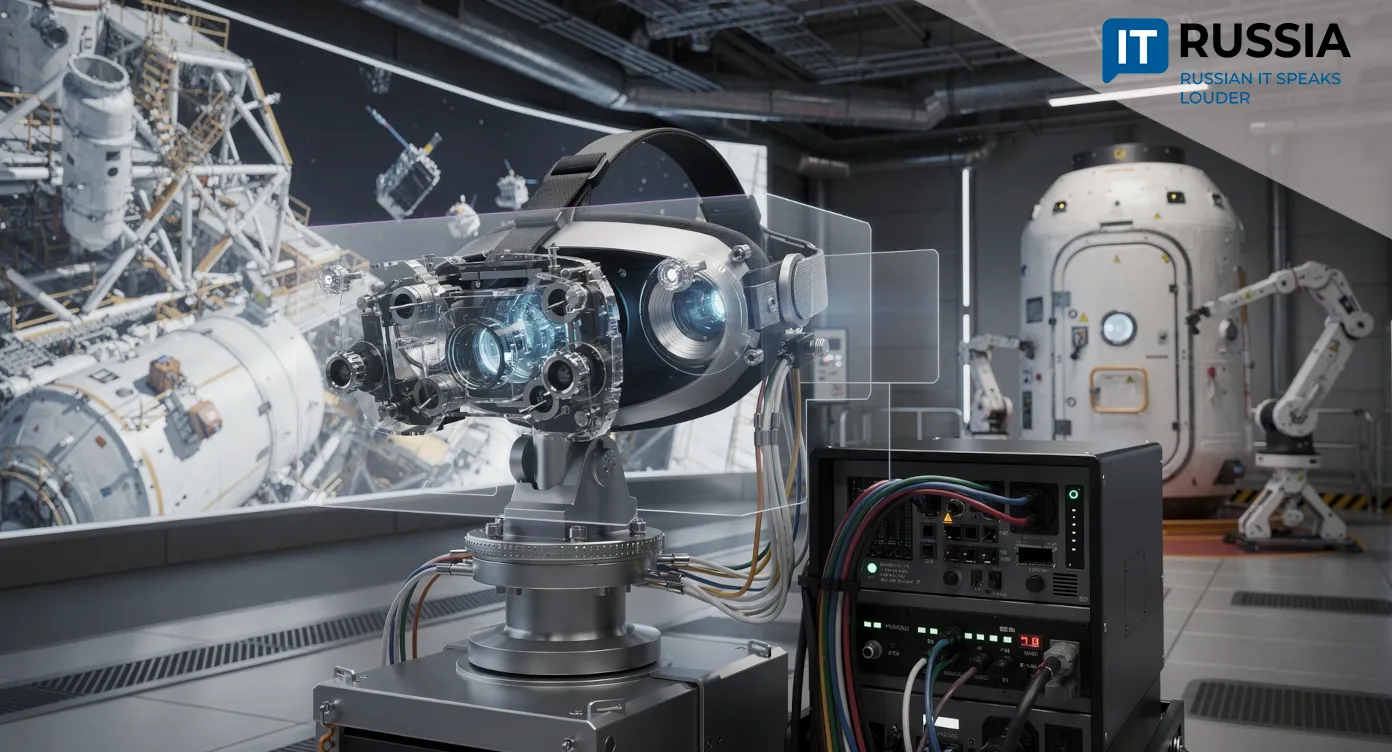

Wireless Diagnostics

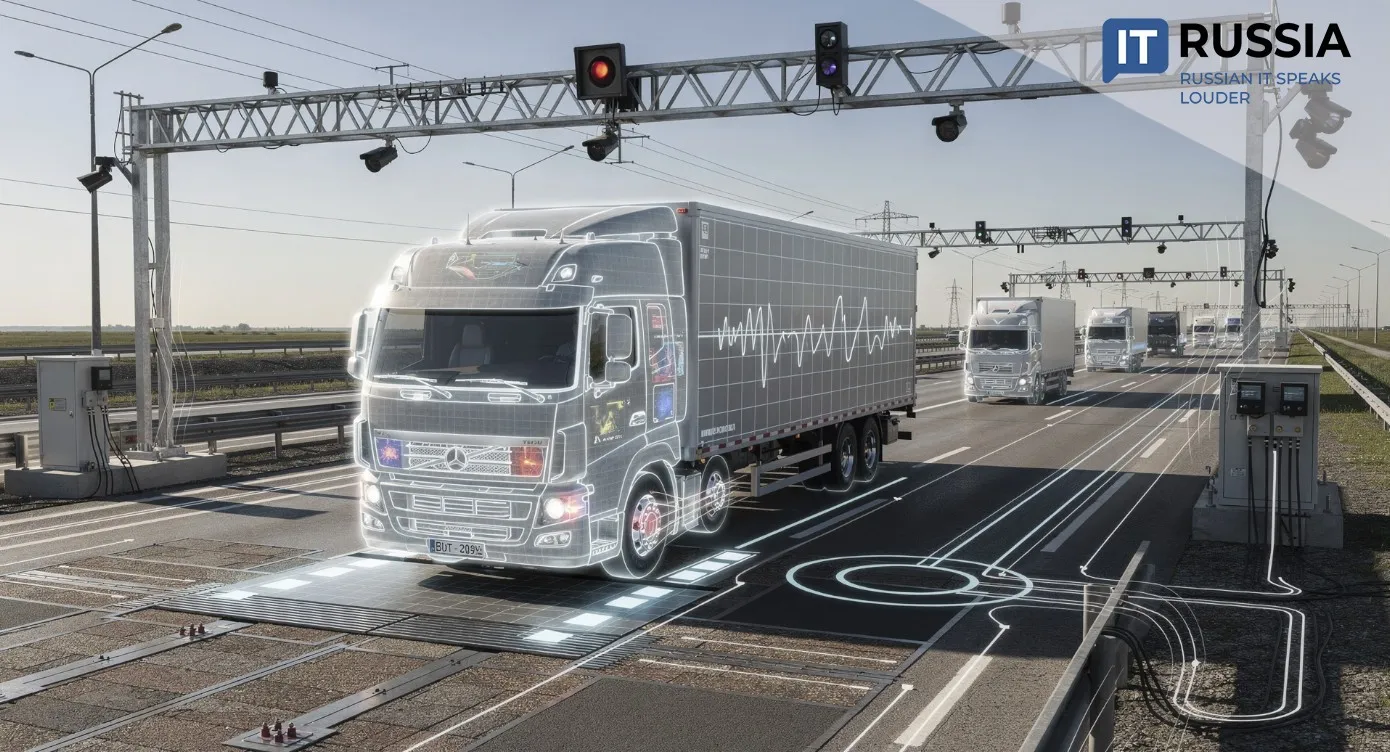

The new diagnostic equipment works with a wide range of vehicle makes and models thanks to a comprehensive onboard database. Diagnostics are performed faster and with greater accuracy, reducing downtime and labor costs, including the ability to operate wirelessly at distances of up to 10 meters. The system supports passenger vehicles, heavy trucks and specialized industrial machinery.

The adoption of this type of technology may serve as a benchmark for other mining companies, demonstrating how service and technical operations can be digitized. Diagnostic tools have long been standard in automotive service centers, but deploying them within the internal infrastructure of a mining enterprise signals a higher level of modernization in maintenance management.

The scanner features a 10-inch touchscreen display designed to minimize diagnostic time. It specializes in analyzing automatic transmissions, engines and complex electronic systems, areas where precision and speed directly affect operational continuity.

A Technological Response to Expansion

JSC Khiagda, a mining company headquartered in Chita, operates under the Uranium Holding of Rosatom’s Mining Division. It is the only enterprise in Russia extracting uranium through in-situ recovery under permafrost conditions. The company is Russia’s leading uranium producer and one of the largest producers of natural uranium globally. In addition, it is involved in the extraction of gold, lithium and rare and rare-earth metals, including titanium, zirconium, scandium, niobium and tantalum.

In 2019, Khiagda announced the successful completion of pilot industrial operations at its “Smart Polygon” site at the Istochnoye deposit. This made it the first uranium producer in Russia and the only one worldwide to digitize extraction at every stage of the technological cycle – from planning to site reclamation.

In 2020, in cooperation with the Seversk Institute of NRNU MEPhI, the company developed a digital twin integrating financial, economic and production management models. Specialists gained access to real-time monitoring of technological processes in the ore field.

As the enterprise continues to expand, freight volumes are rising, and with them the size of its vehicle fleet. Khiagda operates more than 100 units of transport equipment, making the introduction of the new diagnostic scanner a direct response to production growth and the increasing complexity of asset management.

Culture of Continuous Improvement

Khiagda maintains a consistent focus on operational excellence. The company holds an annual “Leaders of Improvement” competition aimed at optimizing production systems. In 2022, the chief mechanic developed and implemented the best Rosatom Production System project, titled “Optimization of Maintenance for Core Technological Equipment.” Following the reorganization of maintenance, energy supply and productive solution extraction units, equipment servicing and repair times were cut in half. The enterprise also tracks replicable improvement initiatives and conducts regular workplace organization reviews.

Across Russia’s mining and mineral processing sector, digital monitoring and AI-supported decision systems are becoming standard practice. Digital diagnostics tools are expected to be deployed more broadly across industrial service divisions. Looking ahead, integration with IoT devices, augmented analytics and predictive maintenance frameworks is likely. The upskilling of service teams in digital competencies is expected to be a defining trend over the next three to five years.

Although the new scanner is not a standalone IT product, it illustrates the digitalization of operational processes in heavy industry. Improving diagnostic accuracy for mechanical and electronic systems reduces operational risks and strengthens business performance.