Digitizing from the Shop Floor to the Entire Industry

In a breakthrough for industrial analytics, Russian engineers have built an intelligent management system for key sectors of heavy industry. Developed on the foundations of Continuous Intelligence and Object Relations Technique, the platform is designed to optimize production end-to-end – from raw material intake to finished goods.

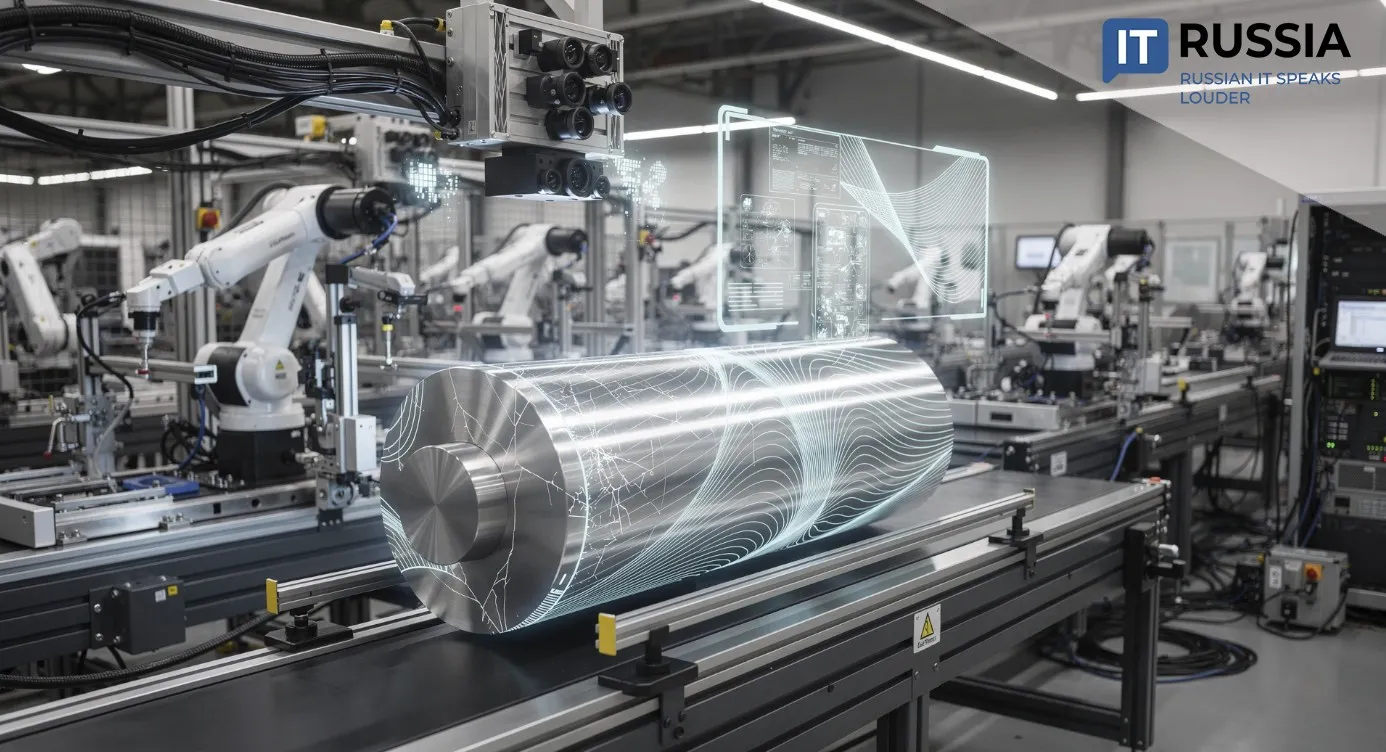

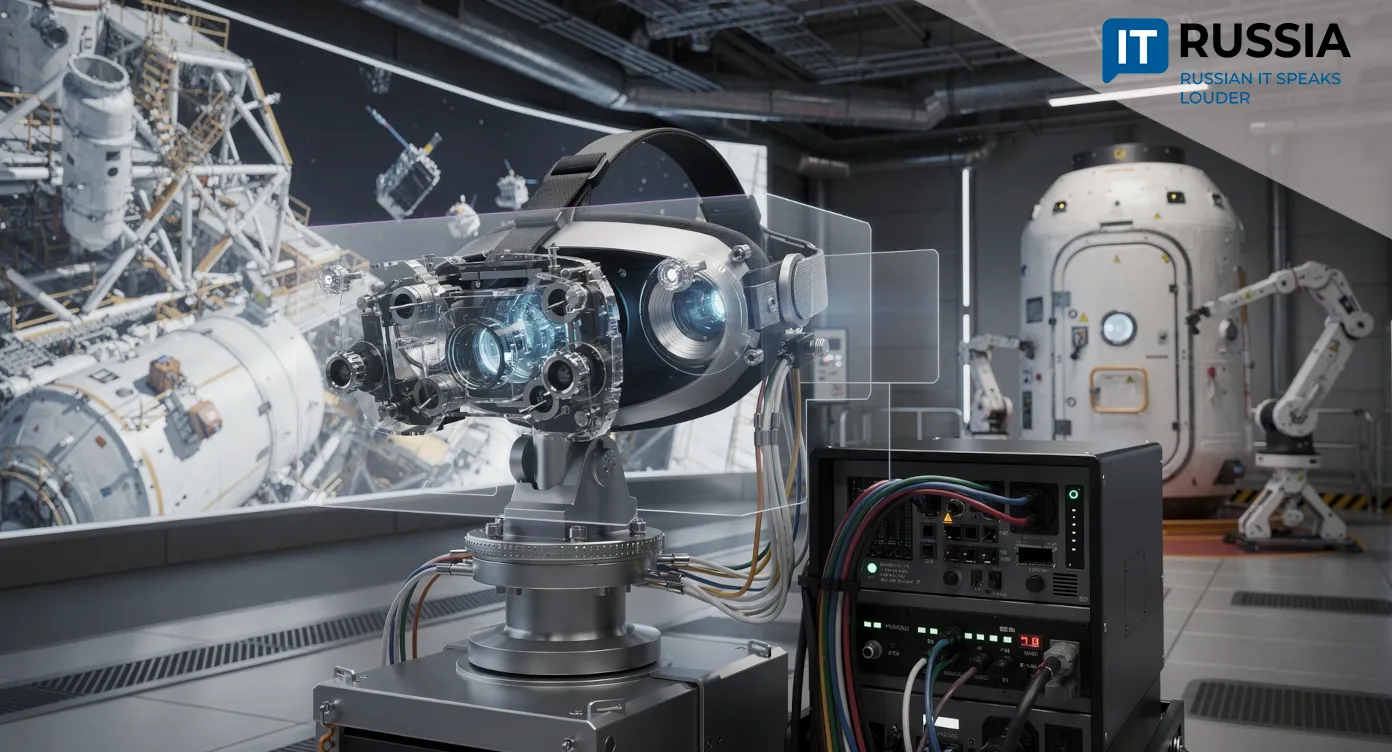

Intelligence for the Factory of the Future

Russian company Data-Center Avtomatika has introduced an intelligent management system for metallurgy, machine building and aerospace manufacturing. Theoretical research behind the project was supported by the Russian Science Foundation. Computational experiments and hypothesis validation involved researchers from the Department of Probability Theory and Computer Modeling and students from Institute No. 8 “Computer Science and Applied Mathematics” at MAI.

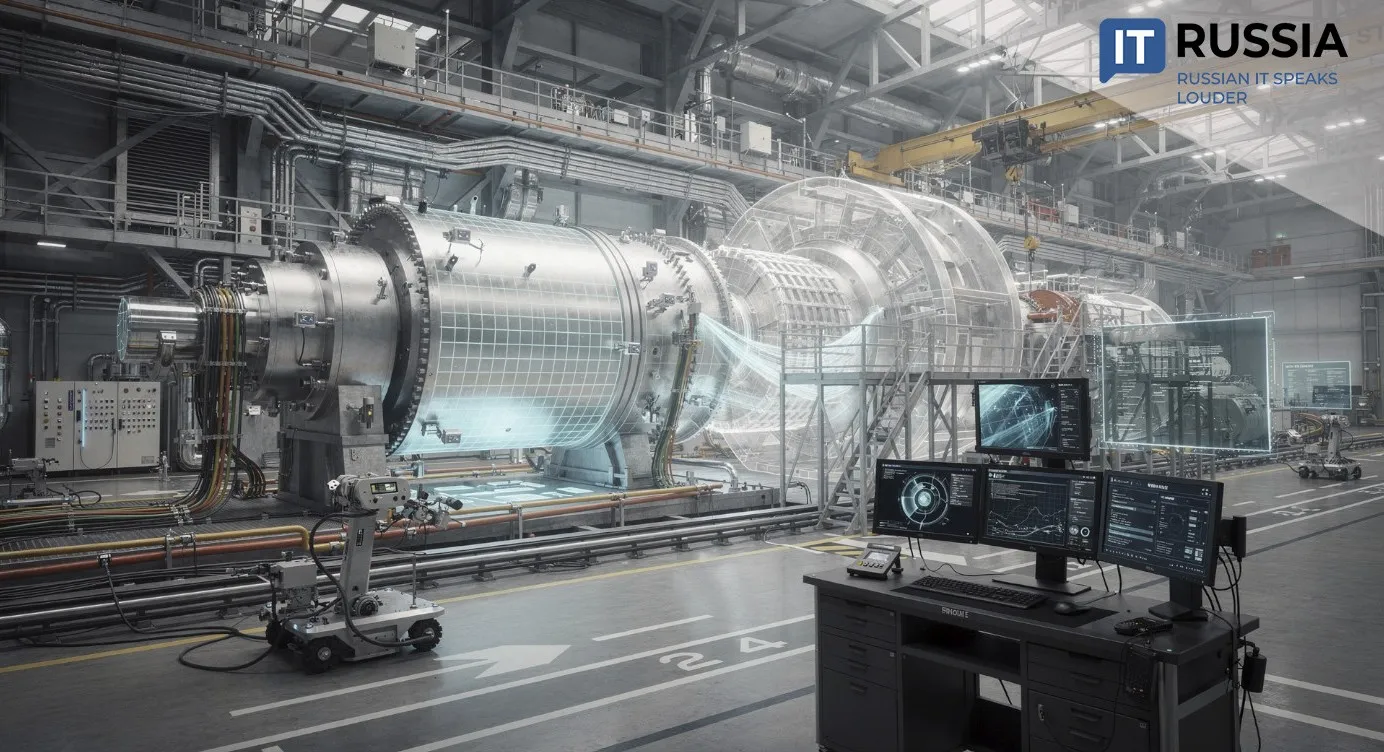

The software follows a modular architecture. Each module performs a distinct function: storing data on products, equipment and technological processes; decomposing complex production tasks into structured stages; building mathematical models; and interfacing with solver algorithms. The system integrates with existing enterprise IT environments rather than replacing them.

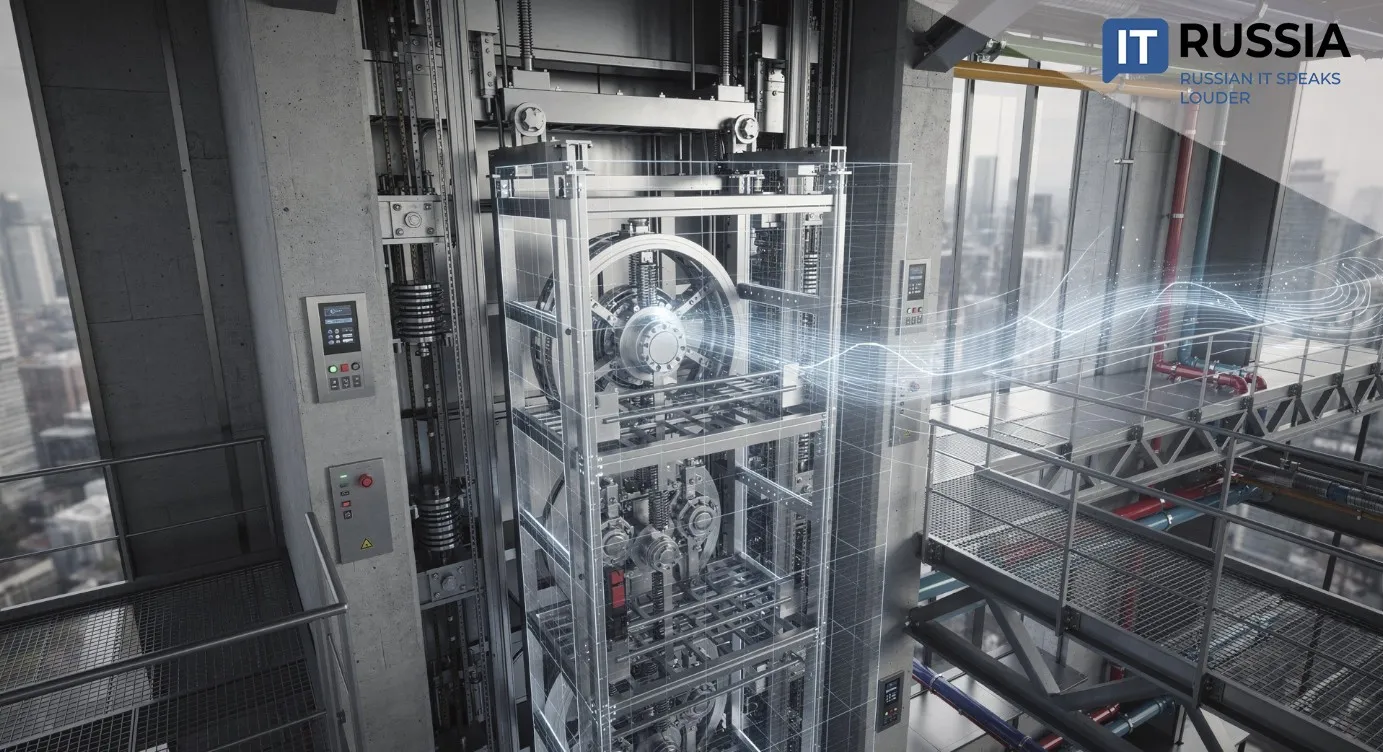

The solution has already been deployed in metallurgical enterprises. The development team is now expanding functionality. A predictive analytics module is under construction, designed to forecast potential production bottlenecks and recommend optimal response strategies. In parallel, adaptive control mechanisms are being developed. The system will be able to self-adjust based on user feedback, increasing operational flexibility and ease of use.

More broadly, the platform is applicable across multiple industrial sectors. It can reduce operational costs, improve delivery schedule accuracy, respond dynamically to production changes and minimize losses associated with manual planning errors.

Precision Planning Without Waste

Data-Center Avtomatika, a leading system integrator in industrial automation, positions itself as Russia’s first adopter of Continuous Intelligence methodology. Its core innovation lies in combining the ORT approach – Object Relations Technique – with continuous analytics. The company’s industrial platforms DATA-TRACK and EXPERT BASE are designed to address critical digital transformation challenges in manufacturing.

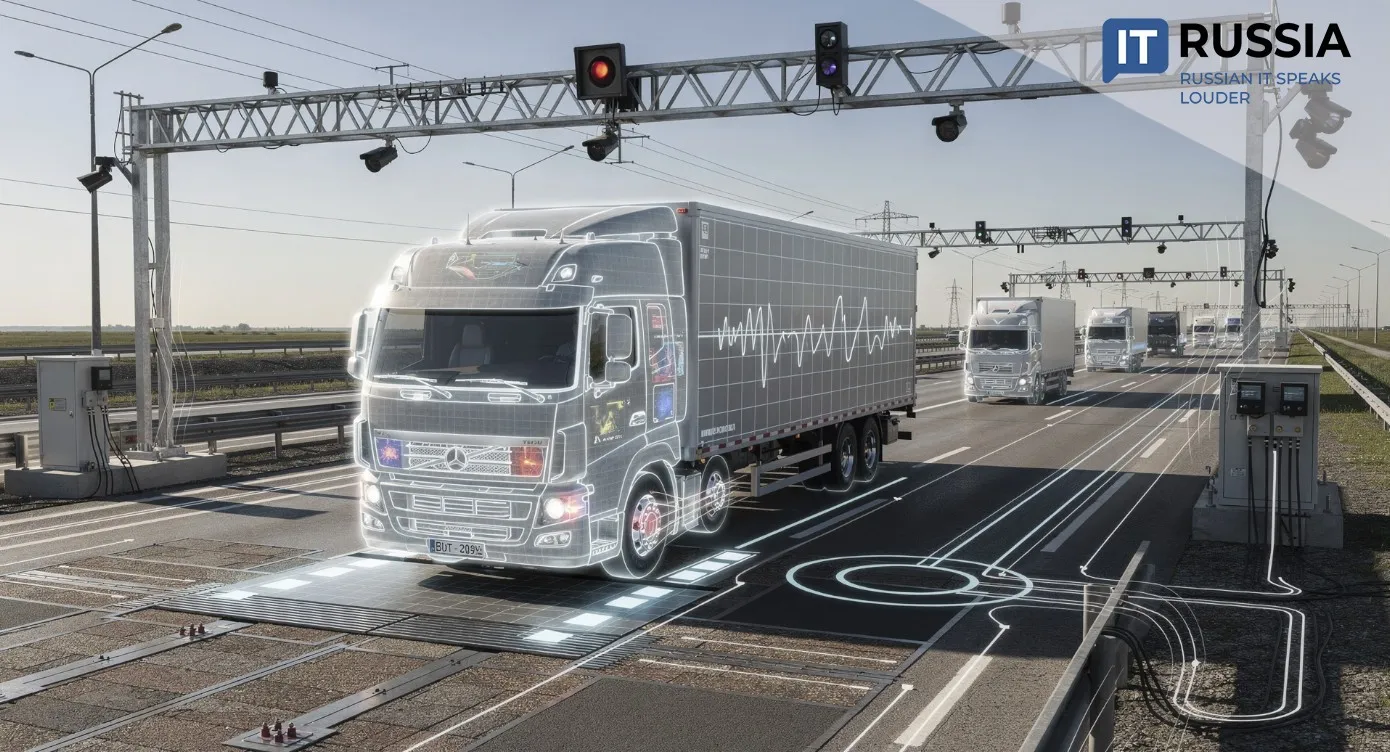

DATA-TRACK is proprietary software that enables enterprises to control material flow, manage processing across technological stages and achieve end-to-end digital traceability – from raw materials to finished products.

EXPERT BASE functions as an enterprise analytics backbone. Its primary objective is to consolidate production data into a unified structure regardless of source or format, enabling experts to conduct production research aimed at optimization and operational improvement.

This architecture allows real-time data processing without waiting for batch uploads from fragmented systems and without isolating analytics into separate silos. The result is a unified production view spanning individual machines to sector-wide analysis. Optimization decisions can be made at a systemic level rather than at isolated operational points.

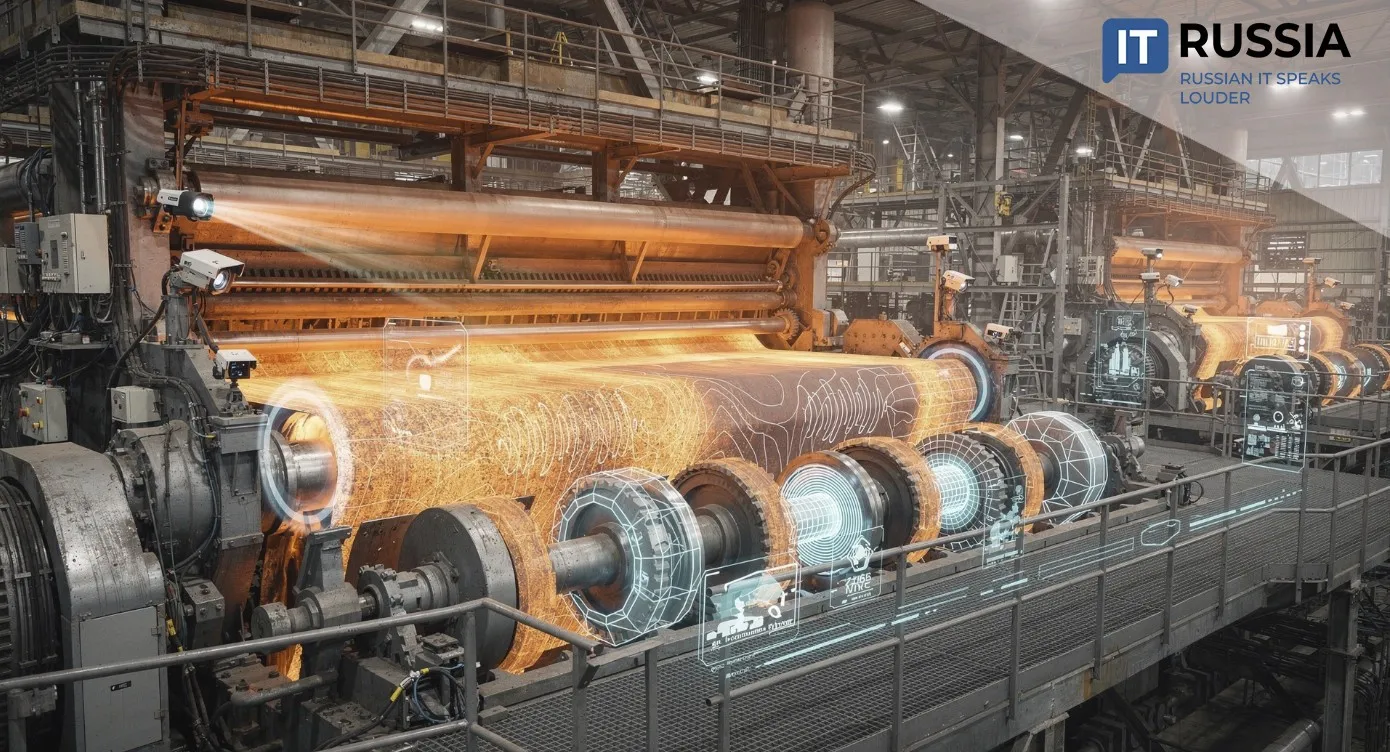

Digital Metallurgy in Practice

Data-Center Avtomatika’s management and end-to-end asset control systems are actively being implemented across Russian industry. A pilot deployment of a full-cycle product tracking system at the Abinsk Electrometallurgical Plant, part of the Novostal-M holding, demonstrated how digital metallurgy can function in practice. By integrating video analytics, Big Data and artificial intelligence with DATA-TRACK and EXPERT BASE, the plant unified information systems across all workshops, centralized technological data storage, reduced equipment downtime and improved product quality.

Among other successful cases is the creation of a unified production data analysis system, “Tekhnologiya,” at the Cherepovets Metallurgical Plant of Severstal. At the Novolipetsk Metallurgical Plant, part of the NLMK Group, a logistics planning and dispatching system for foundry operations was implemented between 2021 and 2022.

From Lab to Global Markets

The joint development by Data-Center Avtomatika and MAI researchers and students is designed for deployment both within Russia and internationally. The company reports inquiries from major enterprises in Russia and Kazakhstan. Expansion into international markets is expected to focus on BRICS countries.

Equally significant is that the platform is domestically developed. As the project’s implementation shows, homegrown solutions can form a viable foundation for large-scale industrial digital transformation in Russia.