Russia Launches Digital Transformation of Vanadium Production

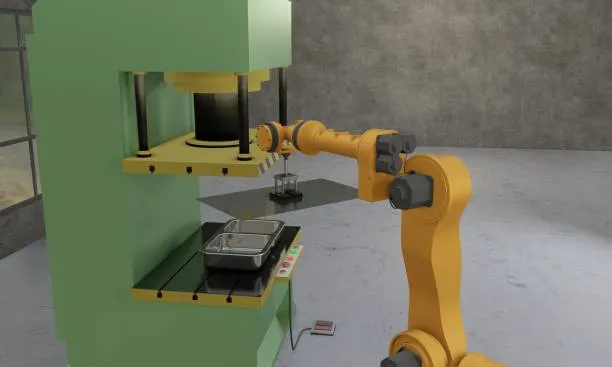

The plant will deploy video analytics to monitor conveyor loads and create a centralized control room for remote equipment management.

EVRAZ Vanadiy Tula has begun a digital overhaul of its wet grinding section in the hydrometallurgical workshop, the company’s press service said.

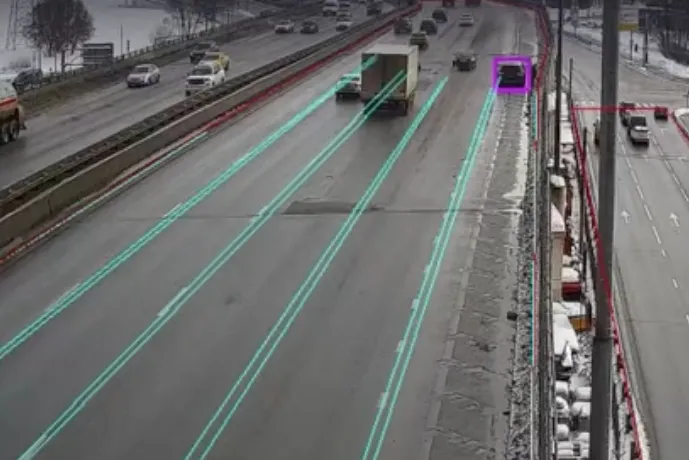

The first stage focuses on introducing video analytics. Five operating conveyor lines will be equipped with industrial video monitoring systems to enable remote oversight of equipment loading.

In the second half of 2026, the plant plans to build two additional conveyors to ensure direct and uninterrupted crushed stone supply to all three mills in the section. The transformation will conclude with the launch of a unified dispatch control room for remote equipment management and process monitoring.

Earlier, EVRAZ’s Tula plant introduced a digital assistant for predictive control of a roasting furnace. The system monitors six critical parameters in real time, flags deviations, and offers recommendations to address issues. This enables operators to anticipate disruptions and respond proactively.

Productivity Gains Through Monitoring

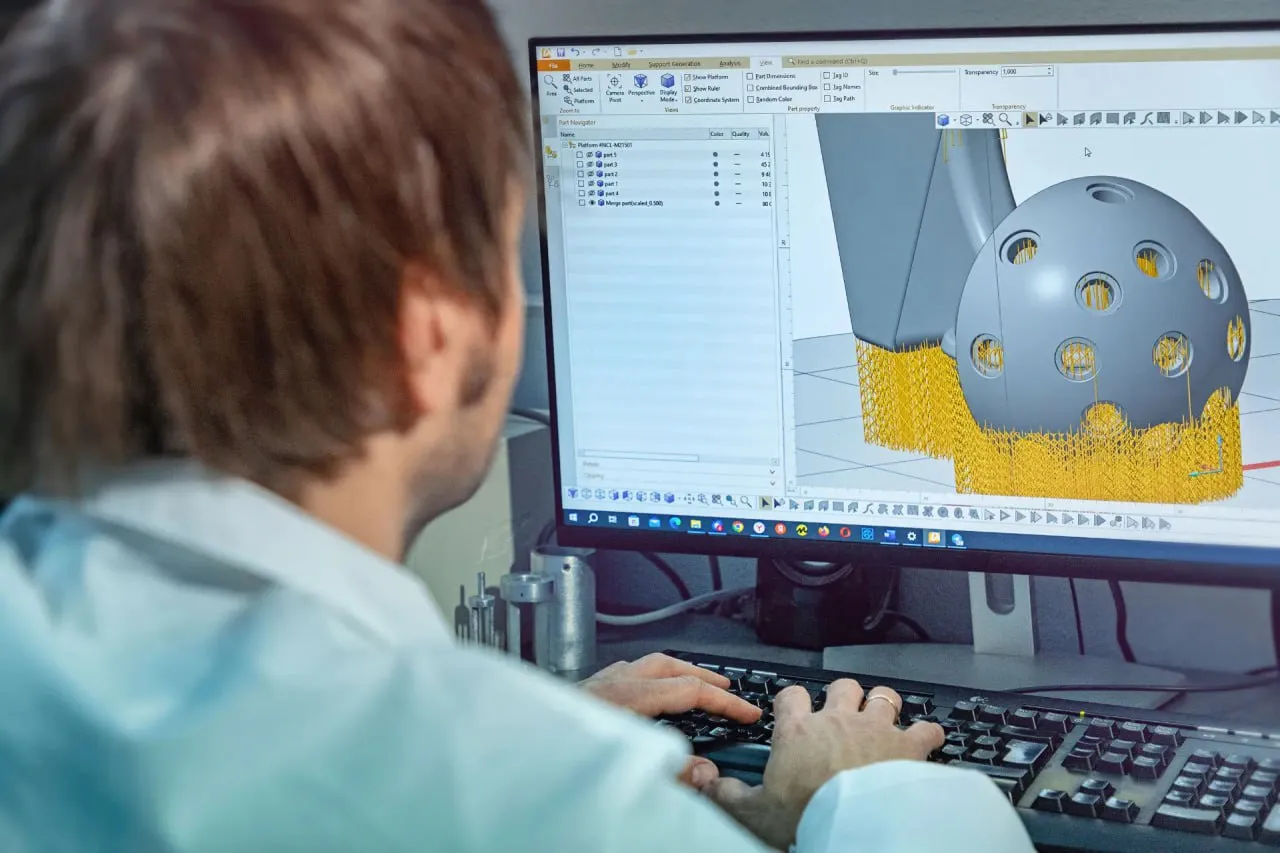

The rollout of digital equipment monitoring systems at other company facilities has already delivered results. Machine efficiency in the mechanical workshop at Zapadno-Sibirskiy Metallurgicheskiy Kombinat (West Siberian Metallurgical Plant) increased by 15 percent thanks to real-time data analysis and reduced changeover time.

Operations of the 40 most heavily used machines are tracked in real time — including operating modes, load levels, and causes of downtime. This allows for more accurate maintenance planning, faster identification and resolution of stoppages, and broader optimization of resources and costs.