Drones First: How Digital Technologies Are Reshaping Industrial Environmental Safety

Norilsk Nickel has modernized its tailings storage monitoring system – one of the most critical and potentially hazardous types of industrial facilities – by deploying unmanned boats and aerial drones.

Safe Industry

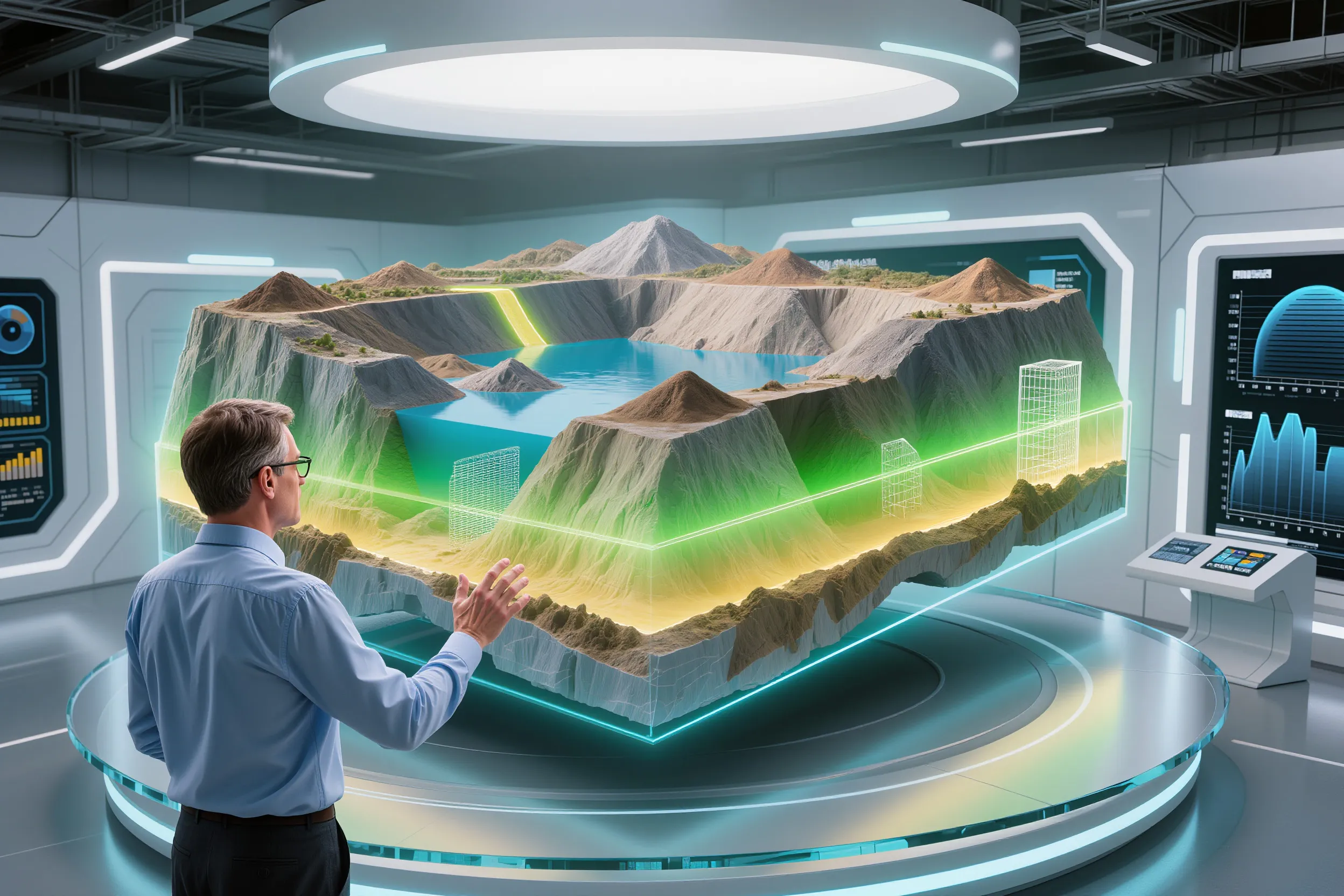

Tailings storage facilities, where ore processing waste is accumulated, require continuous monitoring of water levels, volumes, and the condition of containment dams. Until recently, these inspections were labor-intensive and not always timely. That work is now handled by an integrated system of unmanned technologies. A robotic unmanned surface vessel weighing about 16 kilograms autonomously follows a preprogrammed route, conducting high-resolution bathymetric surveys at intervals of 1–2 meters and collecting millions of data points. Working alongside it are specialized drones equipped with LiDAR scanners and thermal imaging cameras. These drones perform aerial photography and surface scanning even at temperatures as low as –20°C and in strong winds, assessing structural conditions and detecting potential deformations.

All collected data is consolidated into a single digital 3D model of the facility – its so-called digital twin. This model enables highly accurate volume calculations, forecasting of storage capacity, scenario modeling, and early detection of even minor deviations from normal operating parameters.

Preventing Disaster

Following a series of industrial accidents – including the 2020 Norilsk diesel spill, when around 21,000 tons of fuel were released into the environment – Russia has tightened safety requirements for such facilities. Environmental oversight is shifting from a reactive model to a predictive one. As early as 2021, Norilsk Nickel announced plans to use drones and digital models for monitoring tailings storage facilities. By 2024, unmanned systems were already being actively tested at the Skalisty mine.

By deploying digital technologies, the company reduces errors caused by human factors, significantly increases both the frequency and the level of detail of inspections, and, as a result, sharply lowers environmental risks for the regions where it operates.

An Environmental Control Center

The terabytes of spatial data generated through this monitoring process represent a valuable foundation for more advanced analytical systems. On their basis, companies can build predictive analytics platforms, train AI models to forecast potential incidents, and create intelligent asset management services.

According to expert estimates, Russia’s spatial data market could grow tenfold by 2030 – from 51.2 billion rubles (approximately $610 million) in 2020 to 512 billion rubles (around $6.1 billion) by the end of the decade.

Proven methodologies and software solutions developed in this context may be of interest to mining companies both in Russia and abroad, creating a new market niche for Russian technology providers in the field of industrial ecology. In today’s world, safety and efficiency are measured not only in tons of extracted metal but also in gigabytes of accurate data analyzed in time by intelligent algorithms.