Russian Engineers Automate Cable Harness Wire Layout

The new system could dramatically speed up and cut costs in aerospace, automotive, and electronics manufacturing.

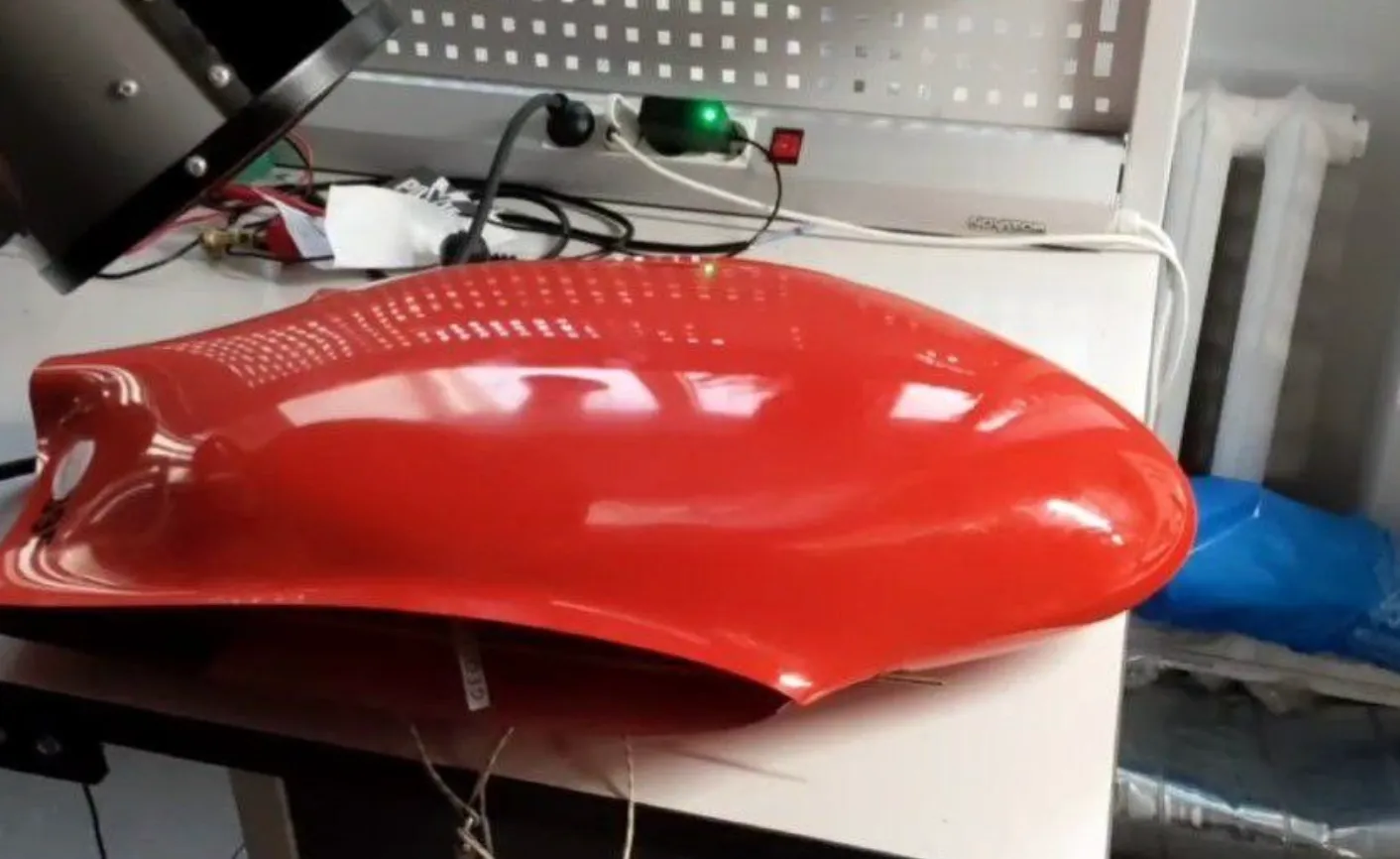

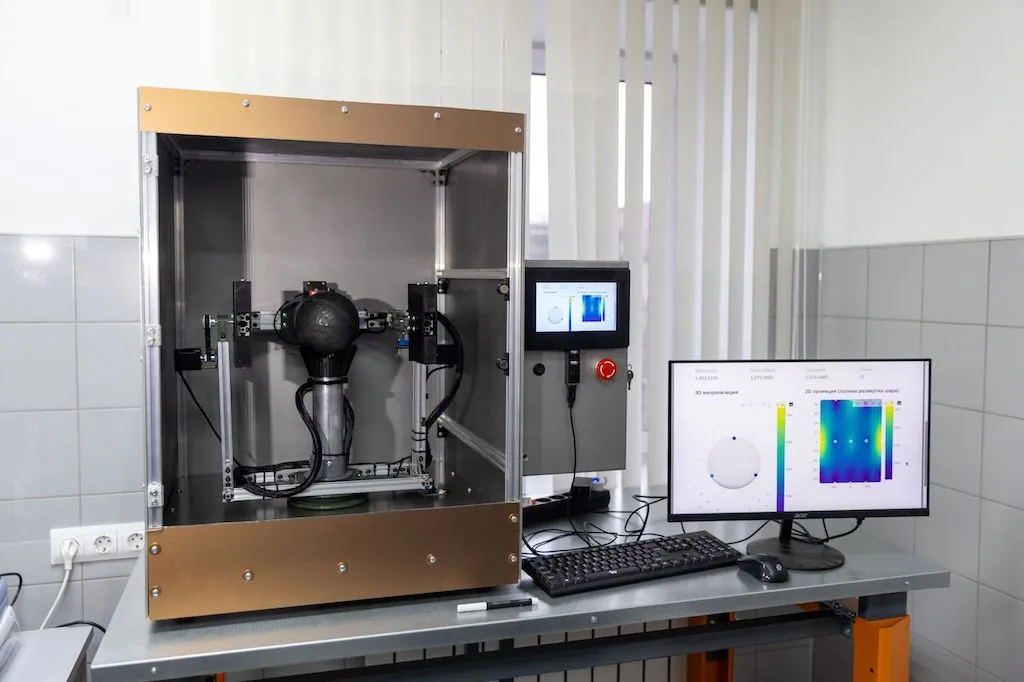

Engineers at the Moscow Aviation Institute have developed an automated machine for laying wires into cable harnesses, the university’s press service said.

At many Russian industrial facilities, cable harness assembly is still done manually. The process is labor-intensive: a one-meter harness can contain up to one kilometer of wiring and around 1,000 connections.

The new system automates this complex process, reducing assembly time from two to four weeks to just six to ten hours. A single operator can supervise the setup, which is designed to run around the clock.

How It Works

Operators enter, review, and adjust harness parameters through the machine’s software interface. Engineers specify wire gauge and length, the number and size of branches, and the total number of connections. The operator then loads spools of wire into the machine, positions connector simulators and support stands, and initiates the layout process. Moving along three axes, the system arranges the wires according to the programmed design, removes the harness blank, and transfers it to the next production stage.

According to Fyodor Vasiliev, head of the Department of Digital Technologies and Information Systems at MAI, the machine’s software can be reconfigured for virtually any type of harness. The system has already passed preliminary commission testing on two standard harness models.