Digital Passport for a Bearing

Ural Steel has rolled out a real-time digital system to monitor bearing wear for predictive maintenance.

Digital Twins as the Backbone of Reliability

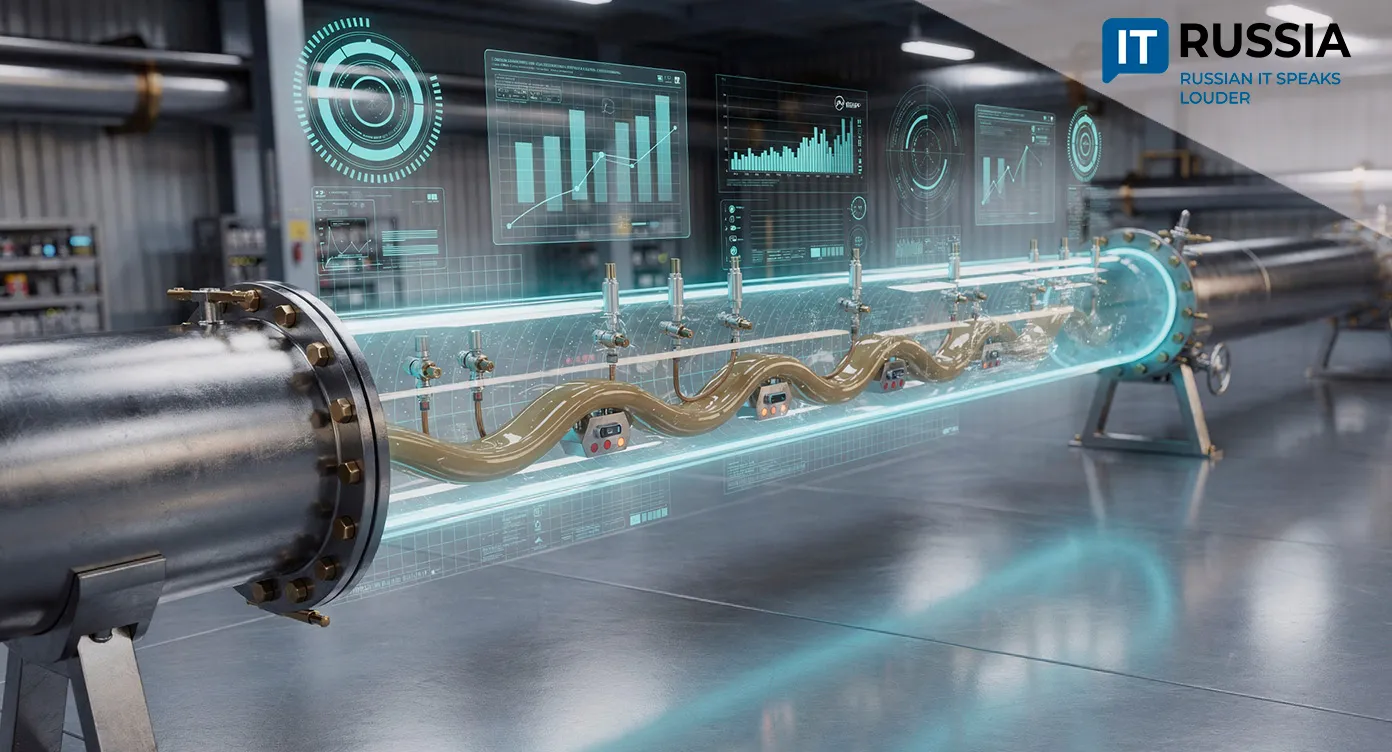

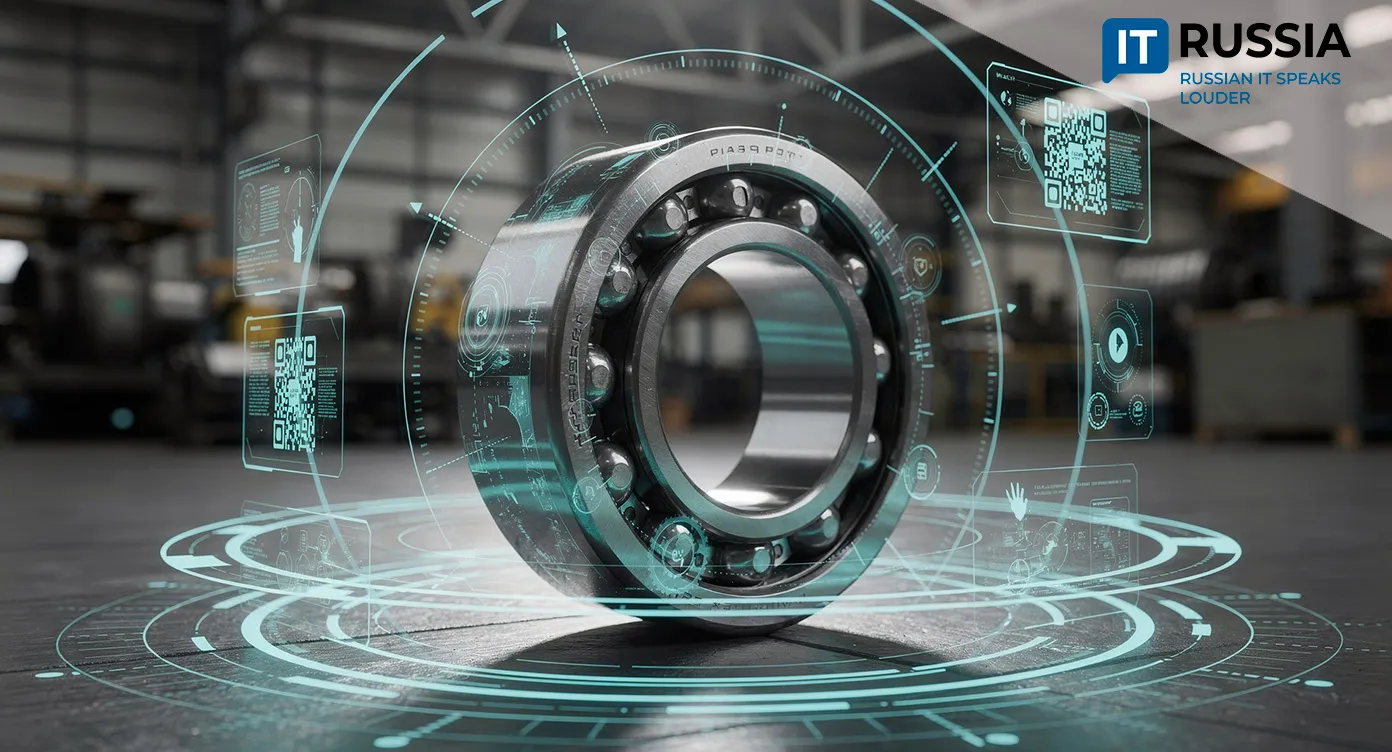

The deployment of an automated system to monitor bearing service life on continuous casting machines at the electric steelmaking shop of Ural Steel marks a shift from a reactive maintenance model to a predictive approach.

Previously, bearings were replaced either after a failure or according to averaged service norms that did not reflect actual operating loads. This led to unplanned line stoppages, higher emergency repair costs, and inefficient use of spare parts. The absence of a unified digital database made objective wear analysis and failure forecasting impossible.

The new system addresses these issues in a comprehensive way. Each bearing is assigned a unique digital identifier linked to its passport data, manufacturer, production batch, and exact installation point on the continuous casting machine. In real time, the system automatically records the number of heats and technological cycles completed, building a precise picture of the operational load on each specific component. Wear levels are visualized through color coding: green indicates normal service life, yellow signals approaching end of life, and red flags the need for immediate replacement.

This approach allows engineers to plan maintenance within the production schedule and avoid critical failures during casting operations. Reducing unplanned downtime improves production stability, cuts emergency repair costs, and optimizes spare-parts inventories. The core innovation – the creation of digital twins – lays the groundwork for further deployment of machine-learning-based predictive analytics, moving equipment reliability management to a new qualitative level and supporting the broader digital transformation of the plant.

Maintenance 4.0

Although the project was initially conceived as a local initiative, its significance extends well beyond a single production unit. It is a representative case of digitizing core maintenance and reliability processes, showing that advanced digital tools can deliver value even for traditional, low-visibility components. Such practices are becoming an important element of the wider digital transformation of Russia’s steel industry. The economic impact will not be immediate and is expected to materialize only after several full operating cycles under new key performance indicators, which calls for patience and a systematic approach to performance assessment.

From an export perspective, the system is of interest to countries with large steel industries – including India, China, and Turkey – where there is strong demand for specialized predictive maintenance solutions. Its competitive advantage lies in real-time operation and forecasting based on actual usage cycles rather than averaged norms. Within the plant, deep integration of bearing monitoring with the unified IT ecosystem is planned, including logistics modules, inventory management systems, and corporate platforms such as ERP and PDM. The next phase will involve deploying machine-learning algorithms to improve failure prediction accuracy and extending the system to other critical components, including gearboxes, shafts, and hydraulic systems.

To reduce risks linked to data quality and workforce skills, Ural Steel has also introduced an advanced training system for maintenance personnel based on 3D and VR technologies. Virtual simulators allow specialists to practice repair operations safely, without risking disruptions to production processes or violations of industrial safety standards.

Reliability in Every Detail

Ural Steel is a leading full-cycle metallurgical company in Russia and a market leader in bridge steel and high-tech plate products. Its steel has been used in the construction of more than 100 bridges, including the Russky Island Bridge and the Krasnyi Drakon (Red Dragon) Bridge, as well as facilities for the Sochi Olympics, stadiums for the 2018 FIFA World Cup, and the Moscow City business district. The company has also mastered the production of bimetal and specialized steel grades, including cryogenic and weather-resistant steels.

For Ural Steel, digitalization is not a one-off initiative but a long-term strategy. As early as 2010, an automated process control system for tundish preheating was deployed on CCM-1, developed by Nauchno-Tekhnicheskie Innovatsii (Scientific and Technical Innovations) using the BPLK-022 controller and TRACE MODE 6 SCADA. The system automated control of gas burners, fans, and exhausters, while enabling real-time data collection and archiving. After forming a unified holding with the Zagorsk Pipe Plant in 2022, the company built its own IT infrastructure based on a private cloud operated by ITGLOBAL.COM, ensuring high availability and geographic redundancy for critical services.

Digital Architecture for the Factory of the Future

The new project fits into the global trend of industrial digitalization. Worldwide, manufacturers have long relied on vibration monitoring and IoT solutions to assess bearing condition. However, specialized systems that track the service life of specific components in real time through digital twins remain rare at Russian industrial enterprises.

The introduction of bearing monitoring is not merely an automation of record-keeping but a full-scale digital transformation of the technological process. It replaces subjective judgments with objective data, establishes a foundation for predictive analytics, and serves as a building block for creating a digital twin of the entire production facility. The next logical step is the development of a unified “smart factory” platform at the intersection of ERP, SCADA, and the industrial Internet of Things, where every piece of equipment reports on its condition and enables proactive decision-making.