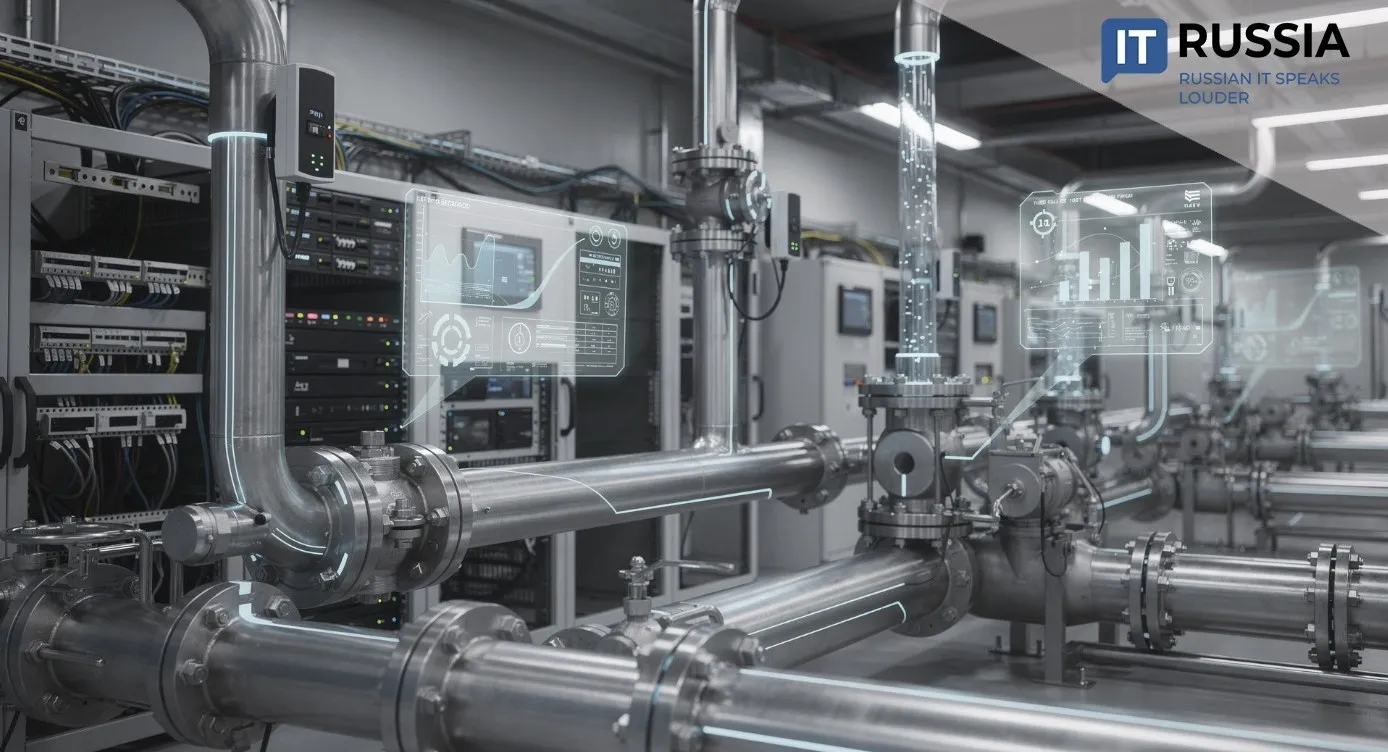

Rosneft Introduces an Innovation for Pipeline Integrity Monitoring

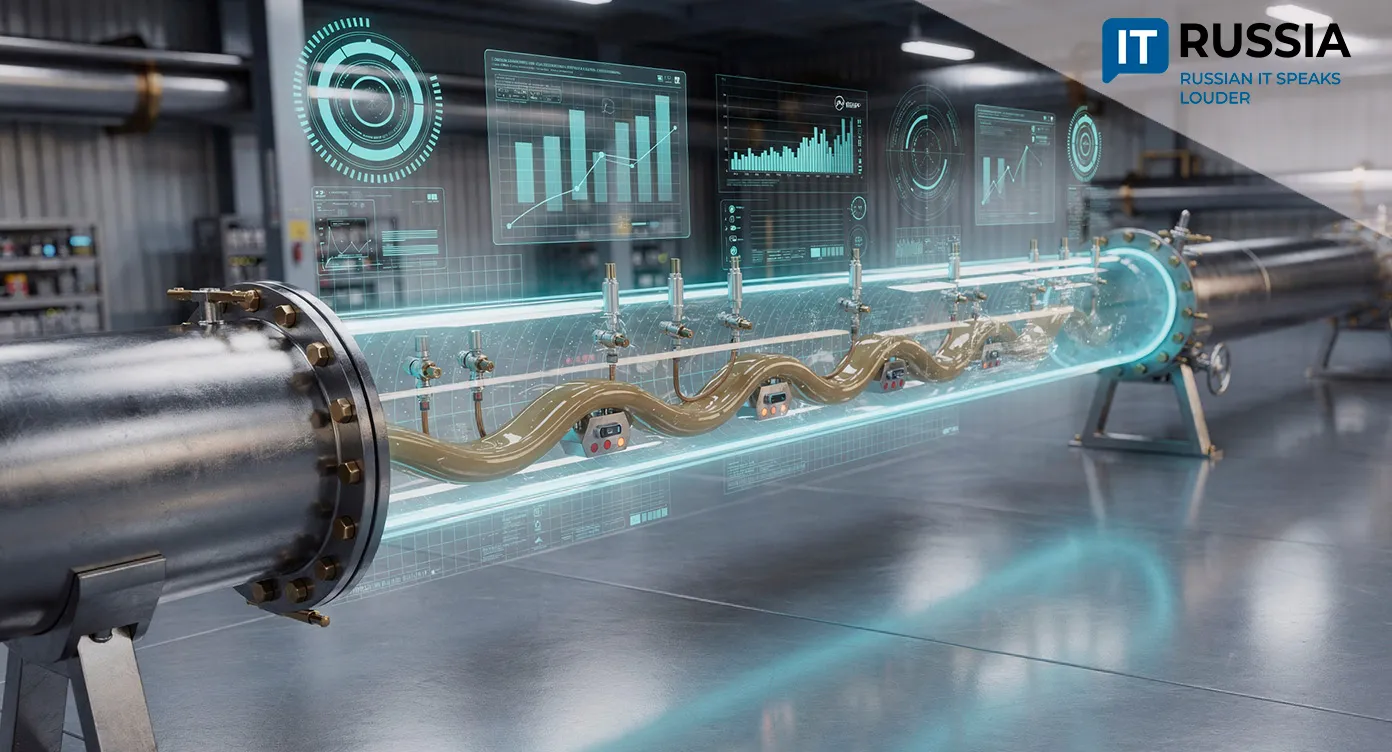

Rosneft has developed an advanced software and analytics system designed to monitor pipeline integrity and improve the reliability of oil transportation infrastructure.

Raising the Bar in the Oil Sector

Specialists at Rosneft’s Ufa research institute have developed and tested a software system that analyses data on transported hydrocarbons and pressure sensor readings in real time. Up to 20 measurements are processed every second. The system automatically identifies the coordinates of a potential loss of pipeline integrity and issues an alert. The software and analytics solution significantly reduces product losses and prevents downtime caused by pipeline incidents.

The product is unique on the Russian market, as it operates even with partially processed hydrocarbons. This solution strengthens the technological capabilities of Russian oil and gas companies in ensuring the safe transportation of hydrocarbons. While the technology is currently focused on domestic needs and the Russian pipeline segment, experts note its clear development potential.

Reliability Pushed to the Maximum

Importantly, the system’s methods and algorithms account for pipeline routing conditions, structural design, and fluid flow regimes. Deployment of the software solution is expected to substantially reduce environmental risks and lower the costs associated with eliminating the consequences of pipeline failures.

The system has already undergone pilot industrial trials at facilities operated by Bashneft-Dobycha, Rospan International, and Samaraneftegaz. In all cases, high efficiency was confirmed. Near-term plans include rolling out the software and analytics system across all pipeline assets of the company. This will involve integration with other digital monitoring platforms and predictive analytics systems. Experts also point to the potential commercialisation of the solution for use by other industry players.

A Long-Term Development Path

As early as 2022, PJSC NK Rosneft reported on the development of software aimed at improving pipeline transport reliability. Specialists at RN-BashNIPIneft, part of Rosneft’s research and engineering division, created a solution for assessing the technical condition and service life of polymer-reinforced pipelines. The development was based on test results from pipeline samples produced by various manufacturers. Researchers identified stress patterns in polymer-reinforced pipelines under internal pressure, temperature variations, and bending loads. The resulting data were incorporated into numerical models, enabling accurate service-life calculations based on operating conditions and pipeline characteristics.

In 2024, Rosneft presented a report on its achievements in sustainable development, highlighting its contribution to environmentally responsible and safe operations. The company is a national leader in deploying innovative solutions in the upstream sector. As part of its innovation development programme, Rosneft actively invests in research and the creation of proprietary technologies, producing advanced digital products that support Russia’s technological sovereignty. Rosneft’s portfolio of science-intensive software includes 24 software products. In 2023, the company implemented and scaled 58 new technologies and concluded more than 100 licensing and sublicensing agreements for software transfer. Rosneft holds more than 1,000 patents. Strategic decisions are guided by the company’s Rosneft 2030: Reliable Energy and Global Energy Transition strategy.

The company continues to develop amid an accelerating trend of digitalisation across the oil and gas industry, including the adoption of AI algorithms for predictive maintenance and infrastructure condition monitoring.