MEPhI’s Atomic 3D Scanner Maps Materials One Atom at a Time

Scientists at MEPhI have developed a unique instrument capable of analyzing the composition of matter at the atomic level. The technology is expected to accelerate the creation of next-generation alloys for Russian industry, from nuclear energy to aviation and biomedical engineering.

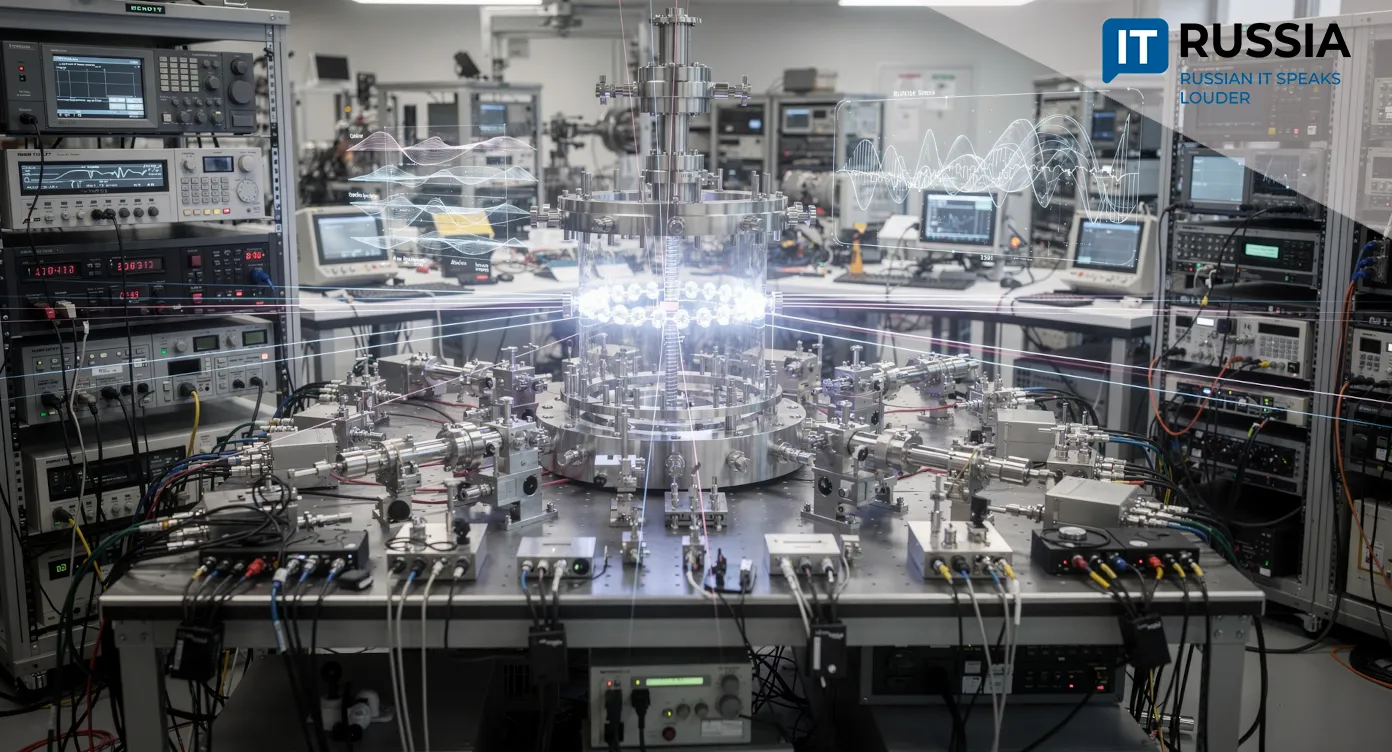

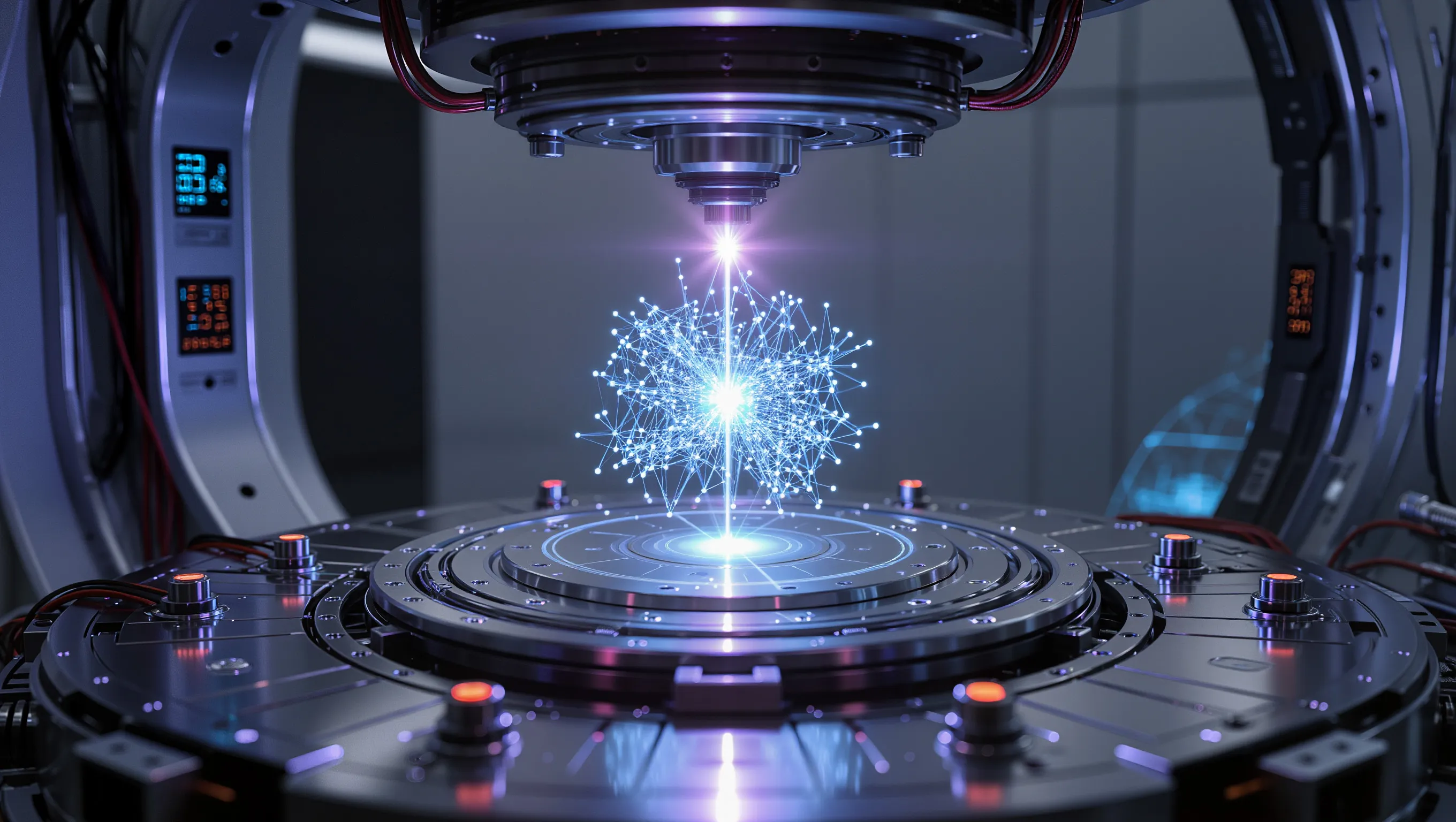

How the Instrument Works

A material sample is placed inside the scanner and exposed to high-powered laser pulses. The substance evaporates layer by layer inside a vacuum chamber, one or two atoms at a time. At the same moment, mass spectrometry determines the chemical composition of those atoms in real time. This approach captures the chemistry of each particle with atomic-scale precision and without distortion.

Using this data, the system builds a three-dimensional map of elemental distribution tied to spatial coordinates. The instrument analyzes millions of data points and reconstructs a detailed model of the material’s internal structure for further study.

The scanner offers several advantages. First, its measurements reach true atomic resolution. Second, the laser-based method avoids mechanical damage to the sample during analysis. Researchers can therefore examine rare or high-value materials without compromising their integrity.

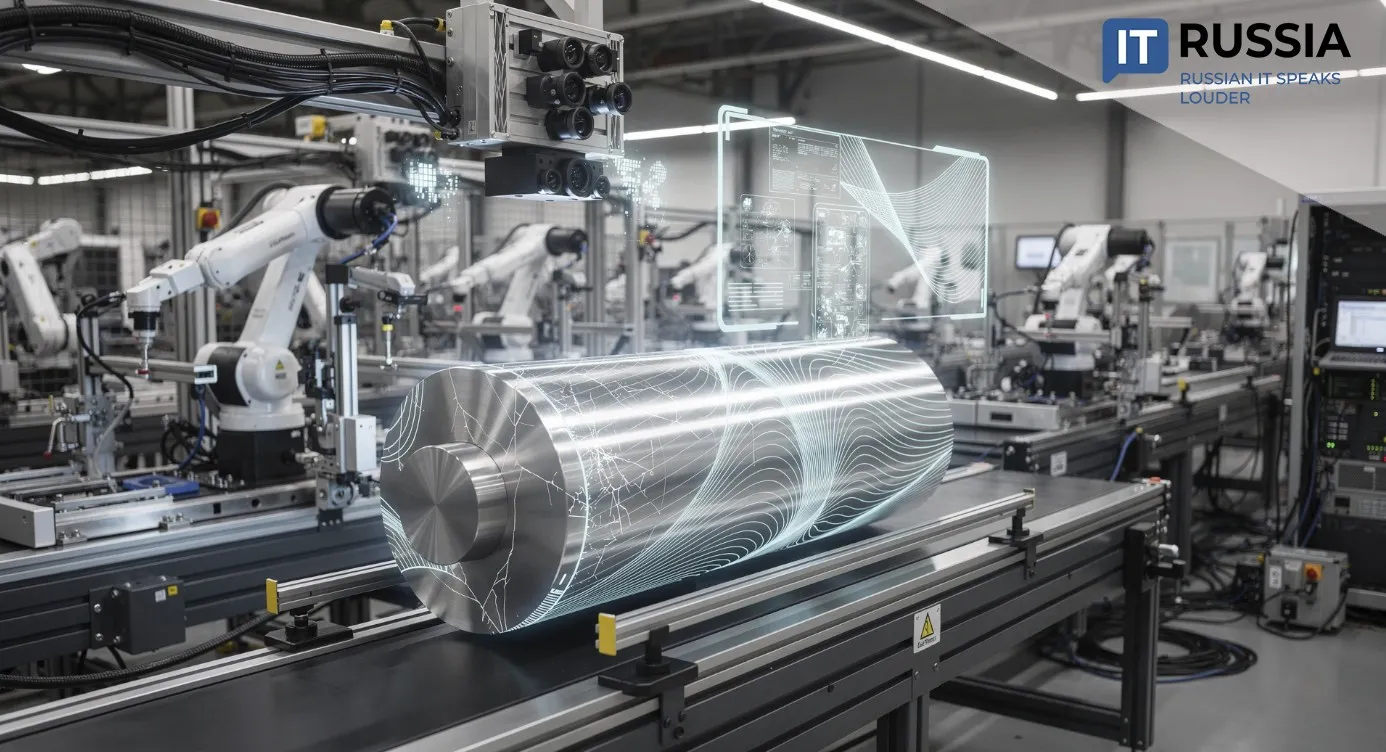

Quality Control for Nuclear Alloys

The nuclear industry requires exceptional material purity to ensure safe reactor operation. Even trace impurities can alter the properties of nuclear alloys and introduce unpredictable risks. The new scanner can detect foreign inclusions at early stages of component production.

By deploying the scanner, specialists can evaluate raw material quality long before installation and operational use of equipment. This reduces the risk of emergency incidents and extends the service life of critical power plant components. The technology becomes a key reliability tool for nuclear facilities.

Engineering Materials for Future Engines

The aviation sector has long sought heat-resistant materials capable of supporting next-generation engine designs. Turbine blades operate under extreme temperature conditions and endure high mechanical stress during flight.

Precise knowledge of an alloy’s atomic structure enables engineers to improve its performance characteristics. With that insight, they can tailor material composition to specific flight conditions and climate zones, increasing engine lifespan and reducing fuel consumption through lighter structural design. In this way, the MEPhI development contributes to advancing Russia’s aerospace manufacturing capabilities.

Promising alloys typically undergo extensive laboratory testing before serial production. The new scanner can shorten the time required to refine composite formulations to their target composition.

From Reactors to Implants

The instrument also opens new possibilities in biomimicry, smart implant design and advanced medical composites. Detailed atomic-scale analysis allows researchers to replicate the natural architecture of biological structures at the micro level. Such materials can combine exceptional strength with biological compatibility in living tissues.

Scaling the Technology

The platform is designed with potential for serial manufacturing and broad industrial deployment. The 3D scanner supports innovation in energy and materials science by enabling rapid laboratory analysis of samples.

In the coming years, demand for such scanners is expected to grow among research centers and engineering design bureaus. The university plans to expand its instrument line for multiple industrial sectors. Partnerships with major companies will support serial production and commercialization, while the resulting innovations are positioned to drive growth across adjacent sectors of the economy and scientific research.