Nornickel Sets Course for Full Drill Automation in the Arctic

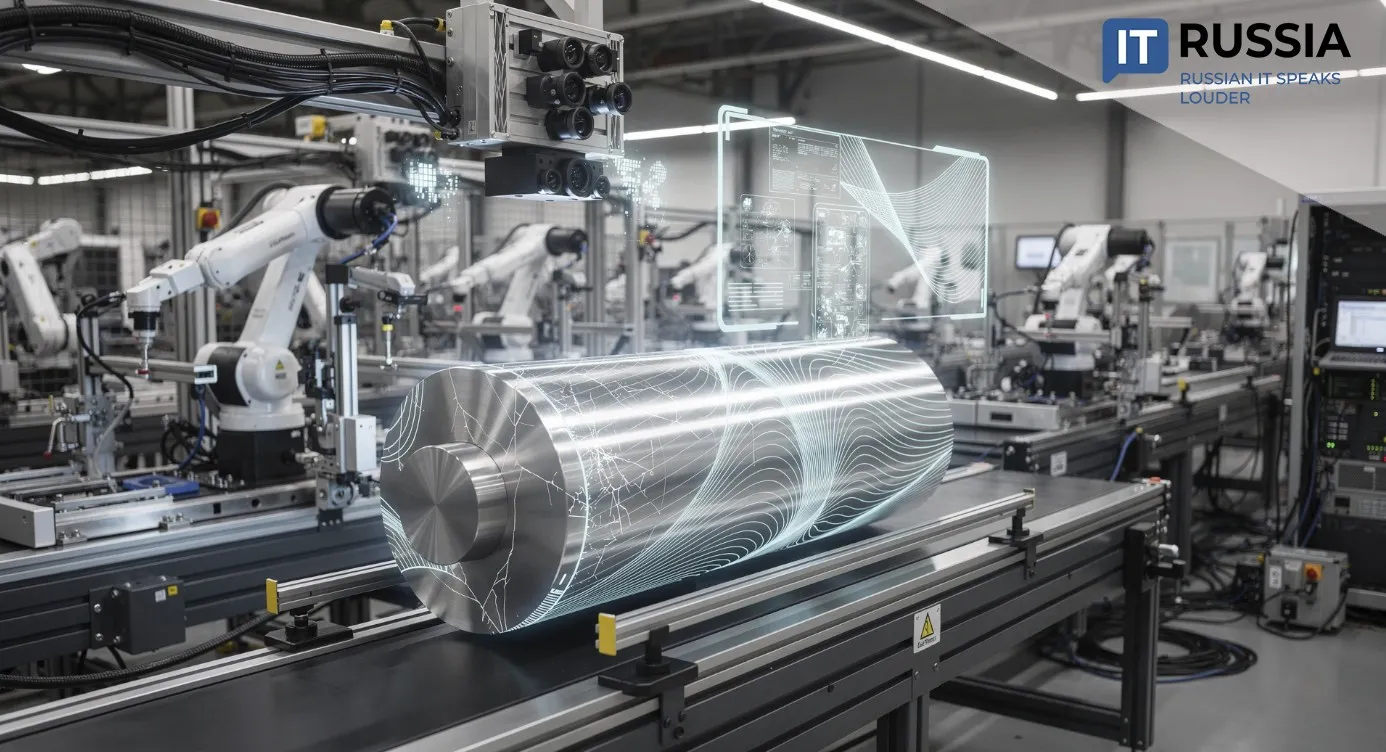

PJSC MMC Norilsk Nickel plans to fully automate drilling machines at its northern mines and shift to a new drilling mode as early as 2026, marking a decisive step in the digital transformation of underground mining operations.

One Year to Modernize an Entire Fleet

Part of PJSC MMC Norilsk Nickel’s drilling fleet is already operating in automatic mode, and the entire fleet of drilling rigs at the Talnakh site of its Polar Division is scheduled for modernization within a year. The company is rolling out digital solutions including machine vision systems, operator decision-support software and digital “passports” for drilling and blasting operations. The move toward full automation aligns with broader digital transformation trends in the global mining industry. These measures not only improve drilling accuracy and operational safety but also reduce the impact of human error in high-risk production environments.

Nornickel is also expanding digital planning and control tools for its core technological processes. That shift comes as global competition intensifies and operational efficiency becomes a strategic imperative. The company is testing domestically developed automated drilling systems. In 2025, the “Assistant for Development Drilling” system successfully completed industrial trials at the Oktyabrsky and Skalisty mines, demonstrating readiness for scaled deployment.

AI at the Core of Industrial Strategy

Nornickel is the world’s largest producer of palladium and high-grade nickel and a leading producer of platinum, cobalt, copper and rhodium. The company is known for a systematic, innovation-driven approach to modernization. Artificial intelligence plays a central role in that strategy. In 2025, Nornickel defined four primary AI development tracks that together generate at least $100 million in annual economic impact. In practical terms, advanced analytics and automation have become a tangible competitive advantage rather than an experimental add-on.

The first of these deeply embedded tools is computer vision. At Nornickel’s concentrators, computer vision systems assess ore particle size in real time. The Talnakh concentrator alone processes seven ore types from four different mines. Hard ore requires slower processing, while softer ore enables time and energy savings. Machine vision evaluates incoming raw material and adjusts parameters accordingly, freeing operators from manual assessment. Its use extends beyond conveyor belts. Since 2023, the company has deployed the “Antinaezd” (anti-collision) system on self-propelled underground vehicles. The system detects personnel not visually but through thermal imaging, adding a critical safety layer in low-visibility mine environments.

The second tool is predictive analytics. Forecasts are built on extensive historical datasets that aggregate operational parameters into detailed, high-resolution process models. The advantage of AI over human operators became especially evident when it was tasked with optimizing flotation, the core process in ore beneficiation. Approximately 40 variables are taken into account, including the chemical composition of frothers, agitation speed and air flow volume. Unlike a process engineer responding reactively to changing conditions, AI identifies an optimal configuration within five to ten minutes, often before deviations affect output quality. Predictive analytics is also applied in flash smelting furnace operations and in chemical analysis stages for both raw materials and finished products.

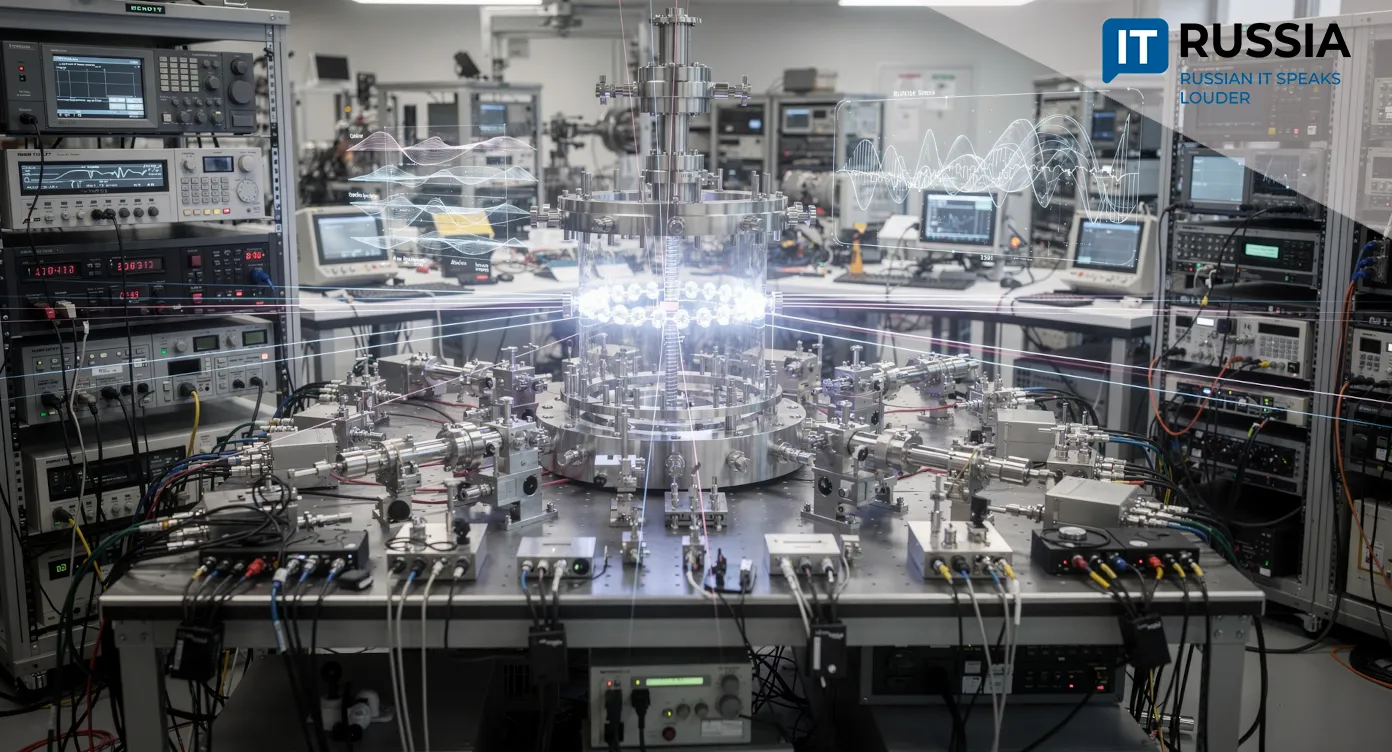

Computer modeling supports both integrated systems and physical processes. It is used in deposit development planning as well as in underground heading and tunneling design. A notable example is Axioma, a digital twin platform developed by Nornickel for broader use across the mining industry. The product enables companies to simulate operational scenarios, test design assumptions and optimize production chains before physical implementation.

The fourth pillar is generative artificial intelligence. Generative AI tools are assigned complex business tasks. Large language models using a retrieval-augmented generation approach significantly accelerate work with technical, legal and regulatory documentation. In addition, generative AI supports marketing and management functions by generating structured insights and scenario options. In a sector traditionally associated with heavy machinery and geology, data-driven decision-making is becoming just as critical as physical assets.

In Line With Global Mining Trends

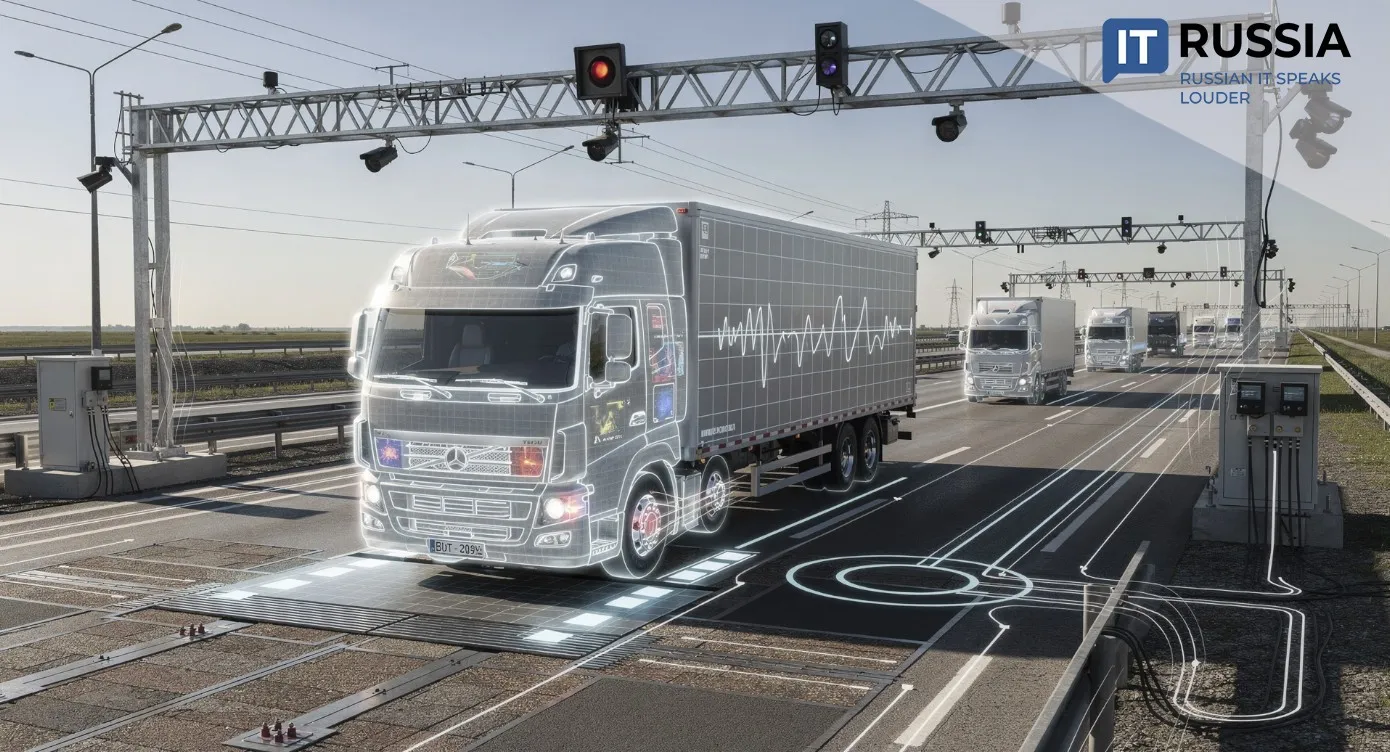

Nornickel’s strategy mirrors developments among major Western mining companies, many of which have been deploying autonomous drilling rigs and haul trucks for several years. In Russia, other industry players have also announced digital initiatives, including automated output quality control systems at SUEK and additional digital mining projects in the Far East.

Technological progress at the drilling stage is likely to serve as a foundation for deeper digital oversight across the entire mining value chain. Automation at the front end of extraction makes downstream optimization more precise, from processing to logistics and metal refining.