Fiber Under Voltage: Russian Scientists Find a Way to See Inside a Transformer Under Load

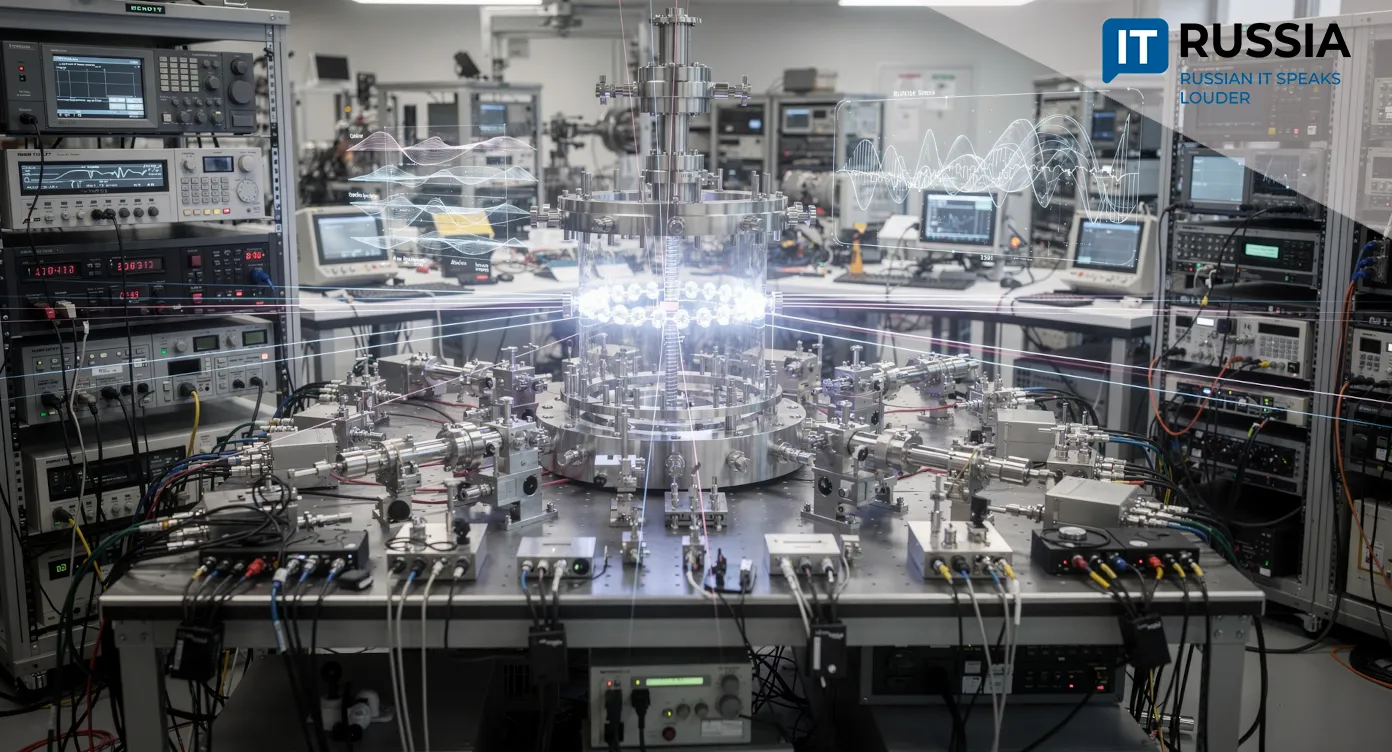

The convergence of optical instrumentation and digital technologies could redefine how power transformers are diagnosed. Researchers in Russia’s Chuvash Republic have developed and tested a new class of devices capable of detecting nearly any emerging fault directly on energized equipment, operating reliably despite electromagnetic interference and other sources of signal distortion.

Optical Insight into the Transformer: A New Era of Diagnostics

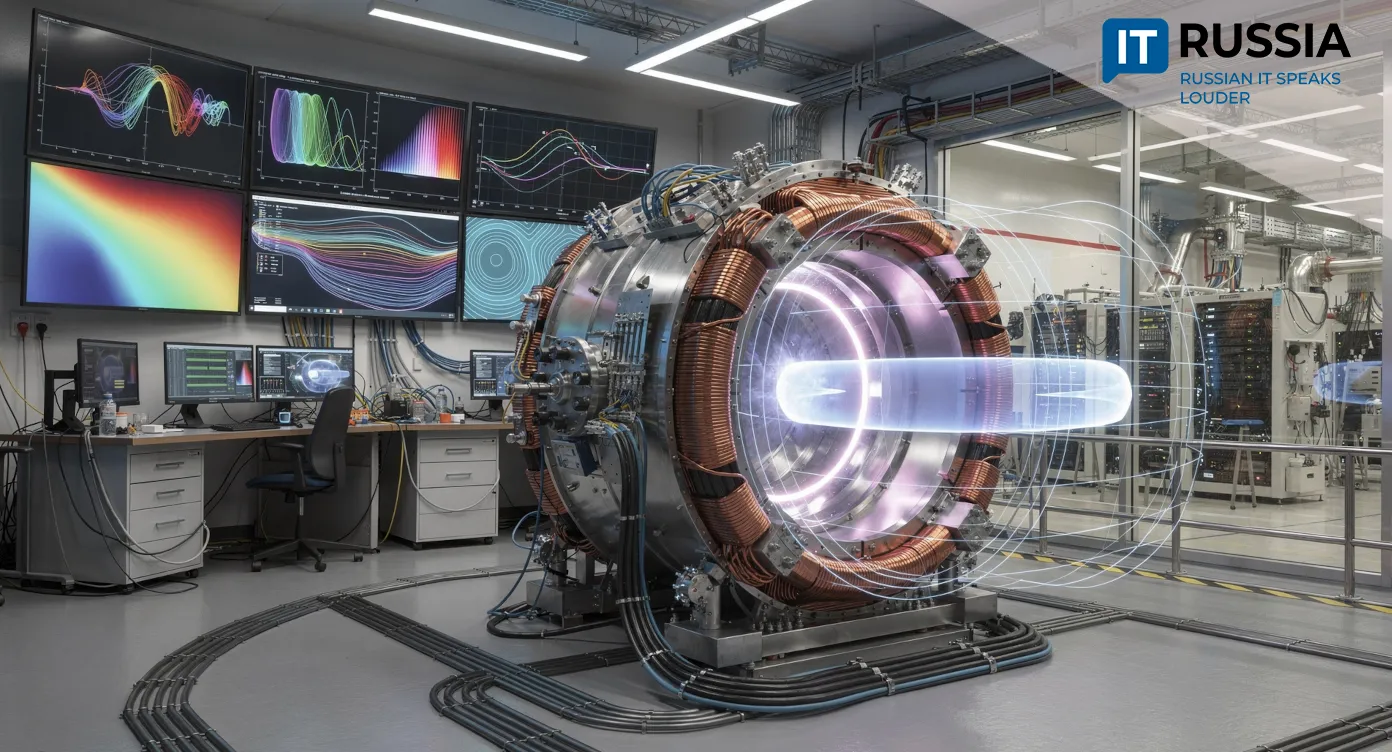

While most conventional diagnostic methods for high-voltage equipment require a full shutdown or suffer from reduced accuracy due to interference generated by energized transformers, a fiber-optic sensor system developed by Chuvash State University named after I.N. Ulyanov, known as ChGU, eliminates these constraints.

The sensors can be mounted directly on operating equipment and function under load. The system is immune to electromagnetic interference and captures winding temperature, vibration, and acoustic signals, transmitting data to a central analytics unit without distortion.

Real-time parameter acquisition enables the use of advanced diagnostic algorithms, including predictive analytics, to identify insulation ageing and early-stage defects before they escalate into failures, helping utilities prevent unplanned outages.

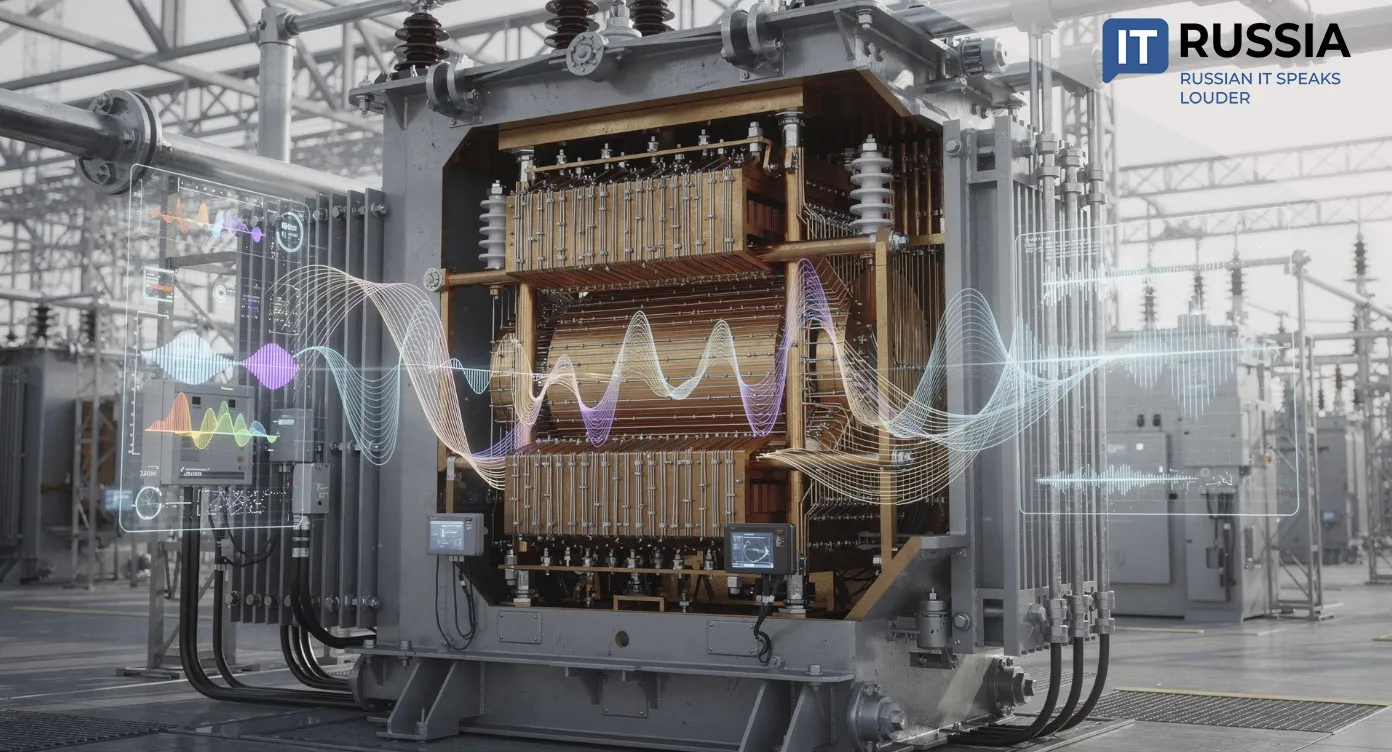

Broad deployment of the technology could significantly reduce the cost of diagnosing oil-filled power equipment. At the consumer level, that would translate into fewer emergency shutdowns and improved reliability of electricity supply. At the industry and national level, it would strengthen Russia’s technological independence in grid infrastructure.

From Cheboksary to Global Power Grids: Scaling the Technology

The system’s operability has already been validated through live trials at an active substation in the Moskovsky district of Cheboksary. The next step is industrial-scale deployment.

According to specialists, more than 70 percent of high-voltage equipment in Russia has exceeded its designed service life, creating strong demand for high-precision diagnostics. The ChGU system can be deployed at virtually any substation and integrated during modernization or construction of thermal power plants, hydropower stations, and distribution networks. Its relevance increases as Russia accelerates digitalization of its grid infrastructure.

International markets also show robust demand for digital diagnostic systems for high-voltage assets. This positions the technology for potential adoption in CIS countries that operate similar equipment, as well as in other partner markets seeking cost-effective modernization solutions.

The Evolution of Power Equipment Diagnostics in Russia

In recent years, multiple solutions for monitoring transformer fleets have entered the Russian market. Most are designed for periodic inspections. However, demand is shifting toward systems capable of continuous condition monitoring or delivering high-accuracy diagnostics within compressed timeframes.

For example, Dalnevostochnaya raspredelitelnaya setevaya kompaniya, part of RusHydro, developed a mobile automated diagnostic system based on dissolved gas analysis in transformer oil after 3.5 years of trials. The system measures nine key indicators and supports forecasting of remaining transformer life. In 2025, the solution received a patent and is being prepared for rollout across other subsidiaries of the holding.

Reliability, Safety, and Operational Independence

The Cheboksary-developed system addresses several operational challenges simultaneously. It is resilient under extreme conditions, enables continuous monitoring under load, and reduces maintenance costs. If deployed at scale, it could provide Russia’s power sector with a functional “nervous system” capable of detecting critical conditions before they result in equipment failure.