Formula for Efficient Turnarounds from DataBriz

Russian industrial intelligence is moving into some of the harshest production environments on the planet. The DataBriz platform, which combines artificial intelligence, advanced analytics, and mobile tools, is not only gaining traction across Russia but is also drawing demand from international operators seeking tighter control over high-risk industrial repairs.

Technologies of the Future Already Operating in the Arctic

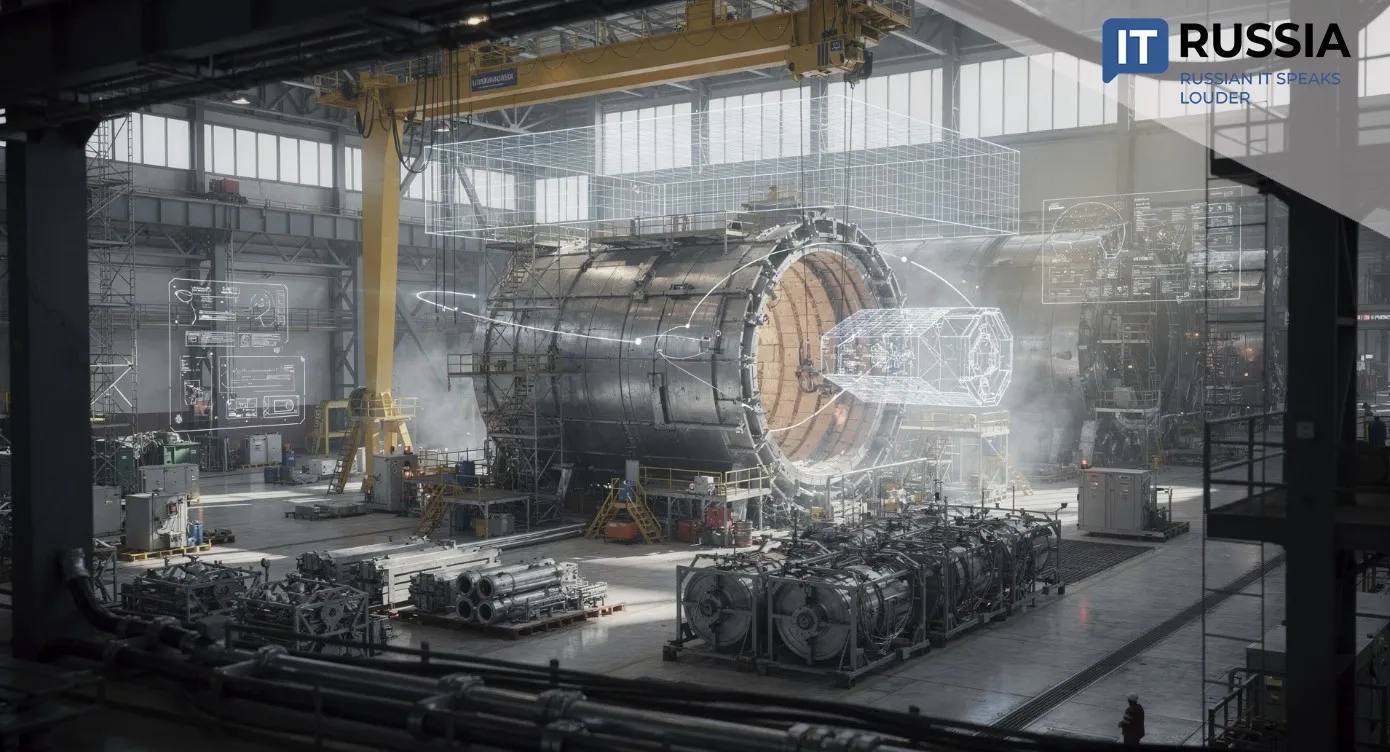

At the Nadezhdinsky Metallurgical Plant named after B.I. Kolesnikov, the largest metallurgical facility in the Arctic and part of Norilsk Nickel, large-scale furnace overhauls have begun using the Russian digital repair management service DataBriz TsUR (Tsifrovoy servis upravleniya remontami – Digital Repair Management Service). The system is being deployed during the capital overhaul of Slag-Cleaning Electric Furnace No. 1, known as OEP 1 (Obednitelnaya elektropech No. 1), one of the plant’s core production units.

Planned shutdown repairs at major industrial sites are not routine maintenance. They are strategic operations in which every minute of downtime can translate into millions of rubles in lost output. The DataBriz software coordinates hundreds of specialists, enforces scheduling discipline, tracks tasks in real time, optimizes resource allocation, and reduces idle time.

Its effectiveness was tested during the most intense phase of the OEP 1 overhaul. When dismantling of the furnace’s lower ring fell 16 hours behind schedule, creating a risk of missing the overall deadline, DataBriz algorithms recalculated an optimized plan almost instantly. Within three days, the delay was eliminated.

In 2024, the service was also used during the technical modernization of the plant’s second production line. It coordinated the work of 2,500 personnel and enabled the project to finish ahead of schedule.

Another case underscores the impact. During the capital overhaul of Flash Smelting Furnace No. 2, the repair timeline was cut by 8 percent. The system processed 974 tasks and more than 8,500 digital reports, giving managers a detailed operational picture throughout the turnaround.

Looking ahead, Norilsk Nickel plans to integrate DataBriz TsUR with video surveillance and 3D equipment models. That step would raise safety and quality control standards for Arctic repair operations, where environmental risks and logistical constraints leave little room for error.

Flexible Planning and Deep Integration

The DataBriz TsUR digital repair management service was developed by Databriz LLC, a Perm-based company specializing in research-driven business management systems built on neural networks and artificial intelligence.

DataBriz is a business process and project management platform listed in Russia’s official domestic software registry. It combines mathematical modeling, predictive tools, and advanced analytics. The system builds multidimensional schedules and allows managers to flexibly allocate both in-house staff and contractors.

One of its core strengths is deep integration with other enterprise systems, including SAP. That simplifies data import and schedule generation. The platform supports multiple operating systems and runs in cloud environments, allowing use across devices and industrial sites. A dedicated mobile app for Android and iOS enables on-site workers to interact directly with planners and supervisors, improving coordination between contractors and plant management.

Field-Proven Industrial Applications

Databriz provides consulting and full lifecycle support for shutdown repairs at energy, mining, metallurgical, and chemical facilities using its proprietary software platform.

The company’s solutions have demonstrated durability under real operating conditions. For nearly five years, its shutdown repair management system has supported production sites of the Azot branch of Uralchem in Berezniki, helping organize and execute large-scale repair campaigns.

In a compressed timeframe, Databriz, working with its partner MAINTEX Fabrica ONE.AI, whose shareholder is Softline Group, reduced the total duration of the capital overhaul of Sintering Machine No. 1 at EVRAZ Kachkanarsky GOK by 15 percent. The sintering machine is a critical production asset that underpins the continuity of the company’s metallurgical cycle. In another joint project, the companies oversaw the overhaul of a primary crushing unit, completing the work 6 percent ahead of the previously planned deadline.

Russian Software Expands into International Markets

Databriz software is also gaining traction abroad. In November 2025, MAINTEX Fabrica ONE.AI announced completion of a pilot deployment of the DataBriz platform for Eurasian Resources Group in Kazakhstan.

The client required a unified digital solution that not only consolidated all repair tasks in one environment but also established planning discipline, provided transparent visibility into project status, and flagged potential risks and performance gaps in advance. Databriz delivered the technological platform, while the MAINTEX team provided methodological and organizational support for change management.

The platform was configured to align with ERG’s infrastructure, including access rights and baseline integration with corporate systems such as SAP TORO (Technical Maintenance and Repair), Mobilnoye TORO (Mobile Maintenance), and Operativnoye Planirovaniye (Operational Planning). The project resulted in delivery of an adaptive DataBriz repair management distribution configured for operation inside the client’s corporate network. The pilot proved the platform’s value, and the parties agreed to continue cooperation through the end of 2027, with plans to scale the solution across other holding companies.

DataBriz has positioned itself as a practical tool for raising the efficiency of industrial repair management. Implementation cases suggest that Russian digital engineering solutions can deliver reliability and competitiveness at scale, and that they are increasingly becoming exportable technology products.